A sealed cabin body of an integral wall plate type spacecraft

An integral wallboard and spacecraft technology, applied in the field of aerospace, can solve problems such as complicated welding and assembly processes, increasing the number of structural assembly units, and reducing the reliability of the cabin on orbit, so as to ensure reliability, reduce manpower operations, and control The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

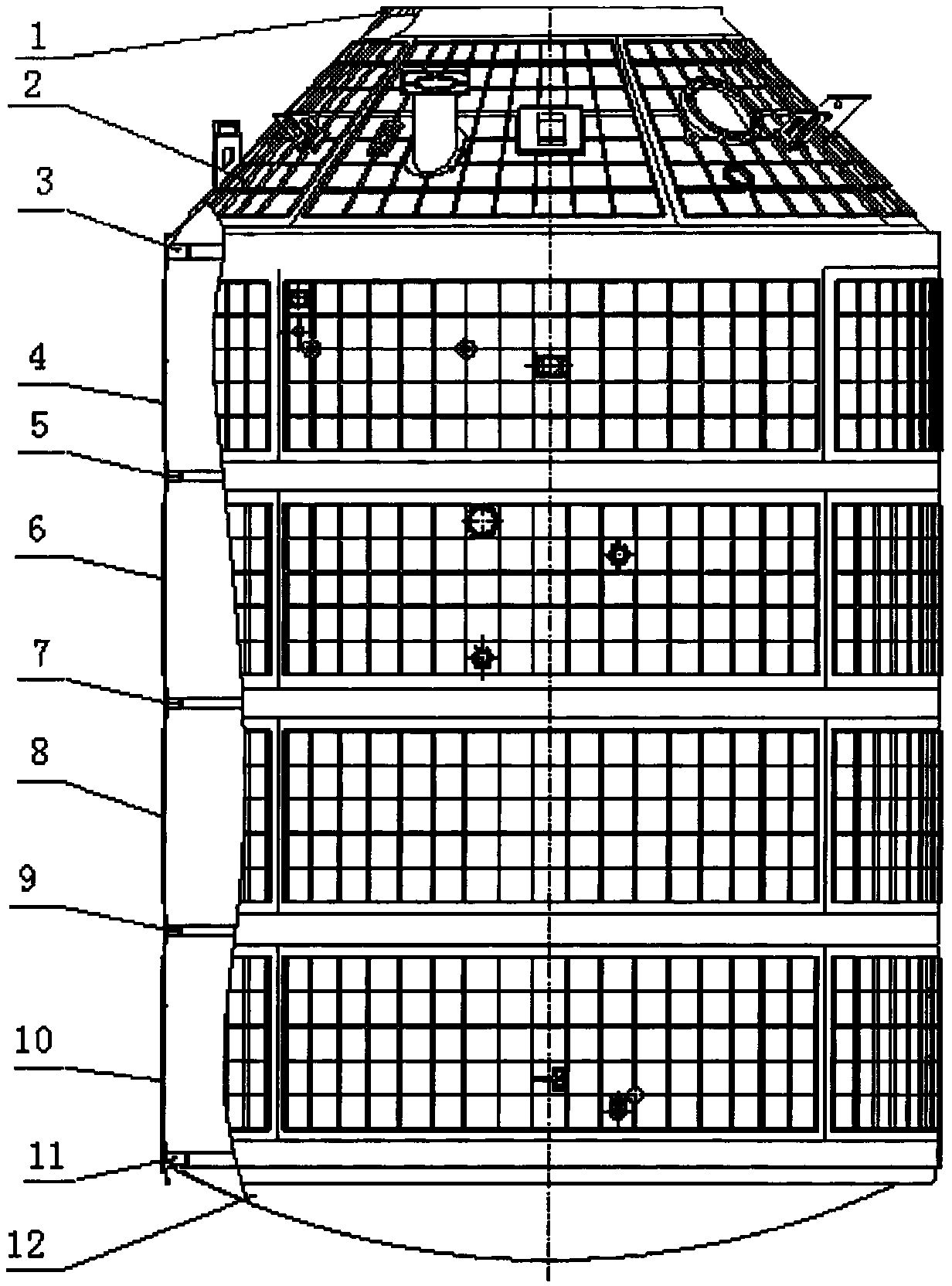

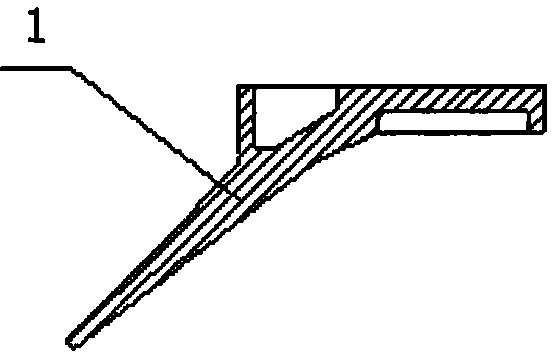

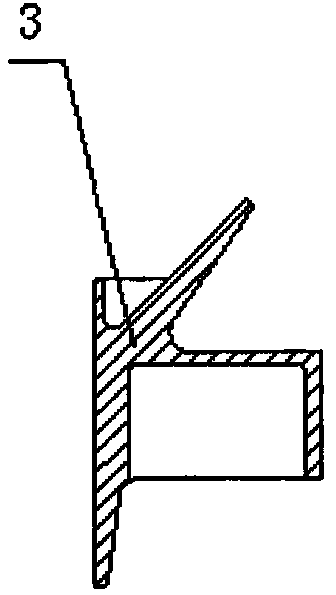

[0017] Such as Figure 1 to Figure 5 As shown, the technical solution for the specific implementation of the present invention is: a kind of integral panel type spacecraft airtight cabin cabin body, comprises front end frame 1, front cone section 2, front connection frame 3, first column section 4, first middle frame 5 , the second column section 6, the second middle frame 7, the third column section 8, the third middle frame 9, the fourth column section 10, the rear connection frame 11 and the sealed ball bottom 12;

[0018] Wherein, the front end frame 1 is a conical shell with an open lower end and a closed upper end; the front connecting frame 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com