BC (Bacterial Cellulose)/PVA (Polyvinyl Alcohol) composite material, as well as preparation method and application thereof

A technology of bacterial cellulose and bacterial cellulose film, which is applied in the fields of medical science and prosthesis, can solve the problem of not meeting the practical application in clinical practice, and achieve the effect of reducing the friction coefficient, satisfying the firm bond and improving the mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of preparation method of BC / PVA composite material, concrete steps are as follows:

[0055] 1 Preparation of medical bacterial cellulose membrane

[0056] Medium composition: yeast powder: 10g, peptone: 6g, MgSO4: 0.2g, CaCl2: 0.1g, glucose: 20g, coconut milk 1000ml, add 10ml of absolute ethanol after sterilization.

[0057] Cultivation method: Inoculate Acetobacter xylinum into the seed culture medium, shake at 180rpm for 18 hours, inoculate the fermentation medium at a ratio of 10%, and culture for 20 days.

[0058] 2 Purification of natural bacterial cellulose products for medical use

[0059] The bacterial cellulose membrane obtained by fermentation is washed with tap water to remove the culture medium, and then soaked in deionized water until the water is colorless and transparent. Then soak 4 times in 3% SDS, replace the SDS solution once every 12 hours; Pure water once.

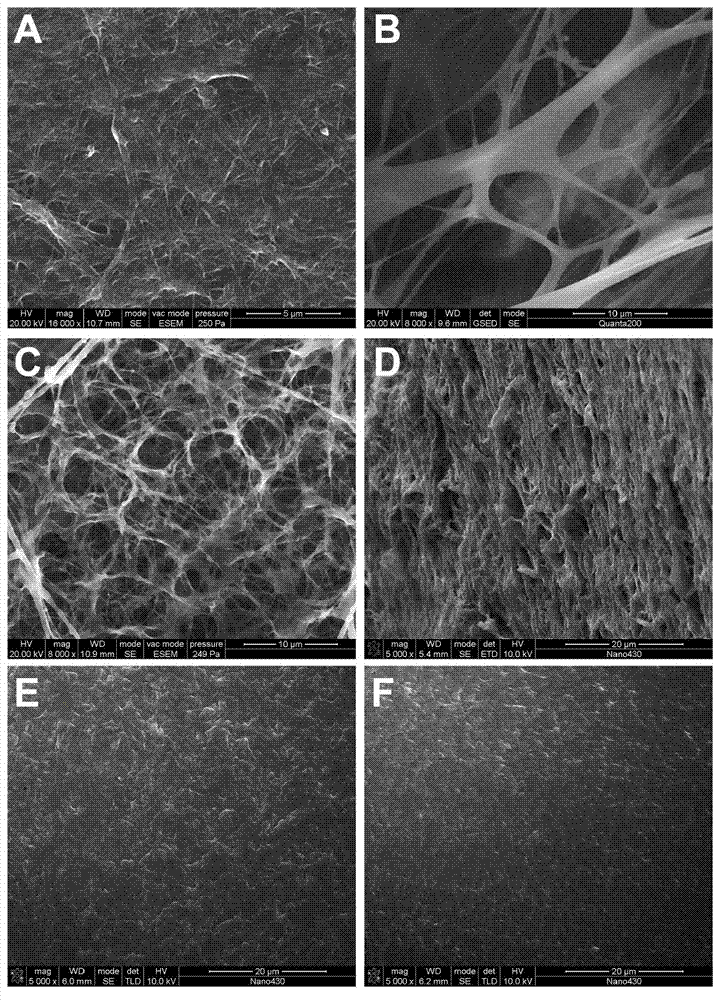

[0060] Such as figure 1 As shown, the L929 cell line (mouse fibroblast cell line...

Embodiment 2

[0074] A kind of preparation method of BC / PVA / PVP composite material, concrete steps are as follows:

[0075] 1 Preparation of medical bacterial cellulose membrane

[0076] Medium composition: yeast powder: 10g, peptone: 6g, MgSO4: 0.2g, CaCl2: 0.1g, glucose: 20g, coconut milk 1000ml, add 10ml of absolute ethanol after sterilization.

[0077] Cultivation method: Inoculate Acetobacter xylinum into the seed culture medium, shake at 180rpm for 18 hours, inoculate the fermentation medium at a ratio of 10%, and culture for 20 days.

[0078] 2 Purification of natural bacterial cellulose products for medical use

[0079] The bacterial cellulose membrane obtained by fermentation is washed with tap water to remove the culture medium, and then soaked in deionized water until the water is colorless and transparent. Then soak 4 times in 3% SDS, replace the SDS solution once every 12 hours; Pure water once.

[0080] 3 Preparation of bacterial cellulose wet film block

[0081] A low-te...

Embodiment 3

[0089] Preparation of polyvinyl alcohol / bacterial cellulose / hydroxyapatite integrated cartilage repair products

[0090] 1 Preparation of medical bacterial cellulose membrane

[0091] Medium composition: yeast powder: 10g, peptone: 6g, MgSO4: 0.2g, CaCl2: 0.1g, glucose: 20g, coconut milk 1000ml, add 10ml of absolute ethanol after sterilization.

[0092] Cultivation method: inoculate Acetobacter xylinum into the seed culture medium, shake and cultivate at 180rpm for 16 hours, inoculate the fermentation medium at a ratio of 10%, and culture it statically for 10 days.

[0093] 2 Purification of natural bacterial cellulose products for medical use

[0094] The bacterial cellulose membrane obtained by fermentation is washed with tap water to remove the culture medium, and then soaked in deionized water until the water is colorless and transparent. Then soak 4 times in 3% SDS, replace the SDS solution once every 12 hours; Pure water once.

[0095] 3 Preparation of bacterial cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com