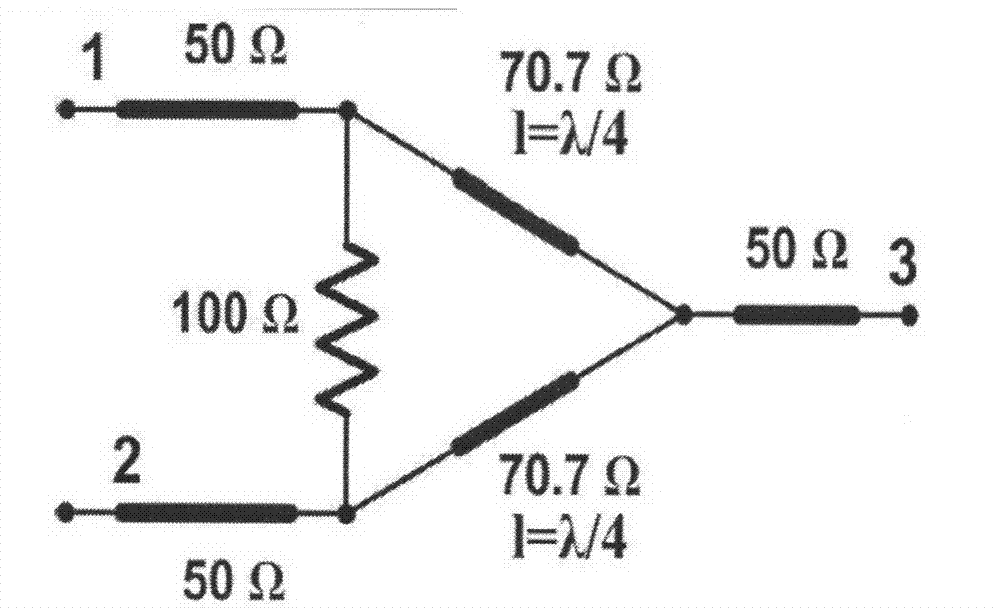

Novel ultra wide band Wilkinson power divider

An ultra-broadband and power splitter technology, applied in the field of microwave and millimeter wave power transmission devices, can solve the problems of Wilkinson power splitter performance degradation, thin film resistance calculation deviation, high manufacturing cost, etc., to improve the accuracy of simulation design and production efficiency, eliminate the influence of parasitic effects, and the effect of good input and output matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

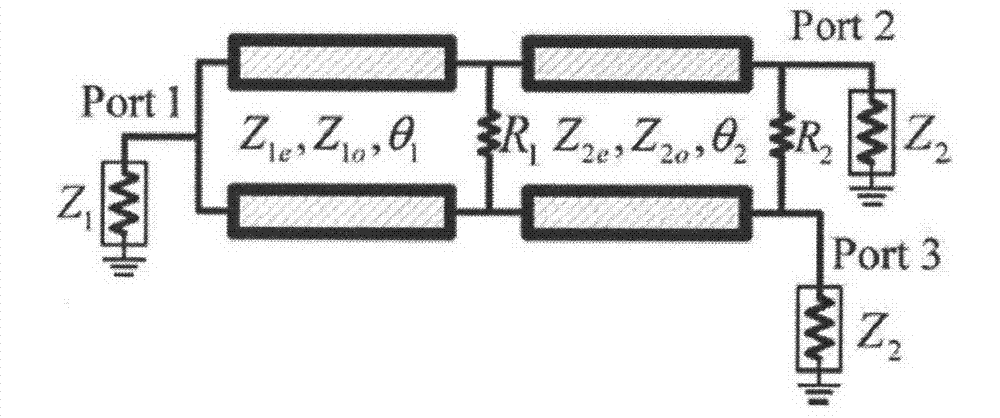

Embodiment 1

[0023] Its structure is as Figure 5 As shown, it is an equal power divider, Figure 6 is the S of the power divider model 11 , S 22 , S 12 , S 23 Schematic diagram of the curve. It can be seen from the graph that the center frequency of the power divider is 4.5GHz, where S 11 ≤-15dB, S 22 ≤-12dB, S 12 ≤0.12dB, S 23 ≤-10dB.

Embodiment 2

[0025] Its structure is as Figure 7 As shown, it is an equal power divider, Figure 8 is the S of the power divider model 11 , S 22 , S 12 , S 23 Schematic diagram of the curve. It can be seen from the graph that the center frequency of the power divider is 4.5GHz, where S 11 ≤-20dB, S 22 ≤-27dB, S 12 ≤0.1dB, S 23 ≤-17.5dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com