Pit-type aluminum ingot heating furnace

An aluminum ingot heating furnace and heating furnace technology, which is applied in the field of heating furnaces and pit-type heating furnaces for small batch production of multi-alloy aluminum ingots, can solve the problems of increasing production and operation costs, energy waste, etc., and reduce heat loss in the furnace , Reduce the height of the factory building, and the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

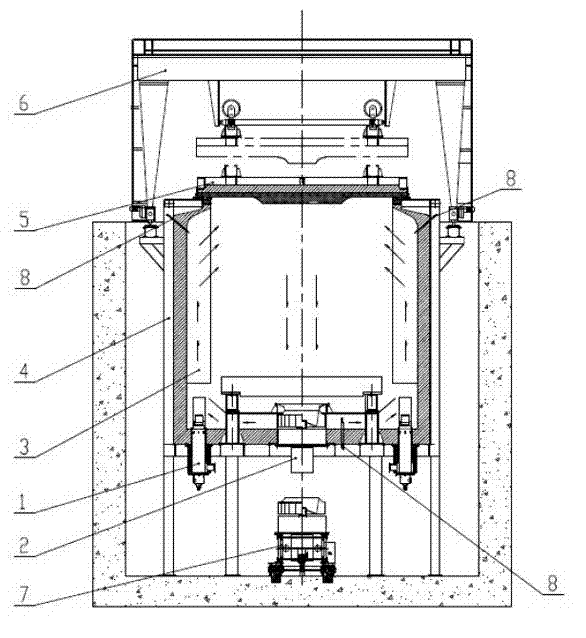

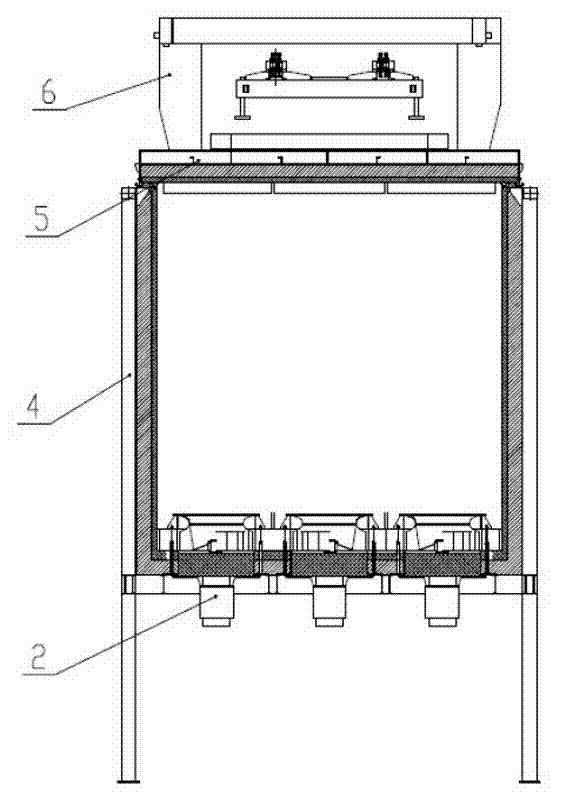

[0024] see figure 1 and figure 2 As shown, the pit-type aluminum ingot heating furnace according to an embodiment of the present invention includes: a heating system 1, a circulating fan 2, a diversion system 3, a furnace body 4, a top-opening furnace door 5, a furnace door lifting and transferring mechanism 6, Circulating blower installation maintenance mechanism 7, and furnace temperature detecting device 8. The top-opening furnace door 5 of the pit-type heating furnace is located on the top of the furnace body 4. After the top-opening furnace door 5 is completely lifted up by the furnace door lifting and transfer mechanism 6 of the furnace body 4 across the furnace body, it is fixed on the floor of the workshop along the The track on the ground and parallel to the running direction of the furnace door is quickly transferred to the designated position and needs to be heated

[0025] The alloy ingots are placed horizontally or vertically into the furnace by a special fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com