All aluminum alloy tank trailer

An aluminum alloy, tank-type technology, applied in the field of tank-type semi-trailers, can solve the problems of being unsuitable for large-scale batch production, low processing efficiency of product parts, and high quality requirements for workers, so as to reduce the workload of secondary processing, The effect of low processing difficulty and improving structural strength and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

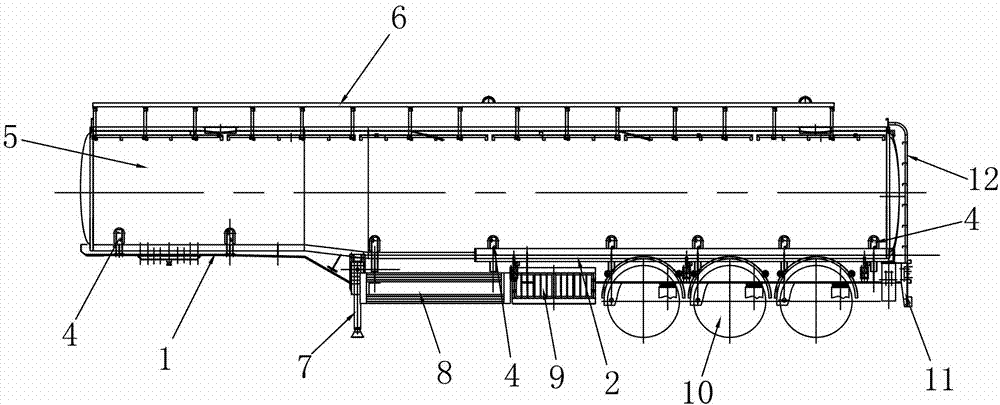

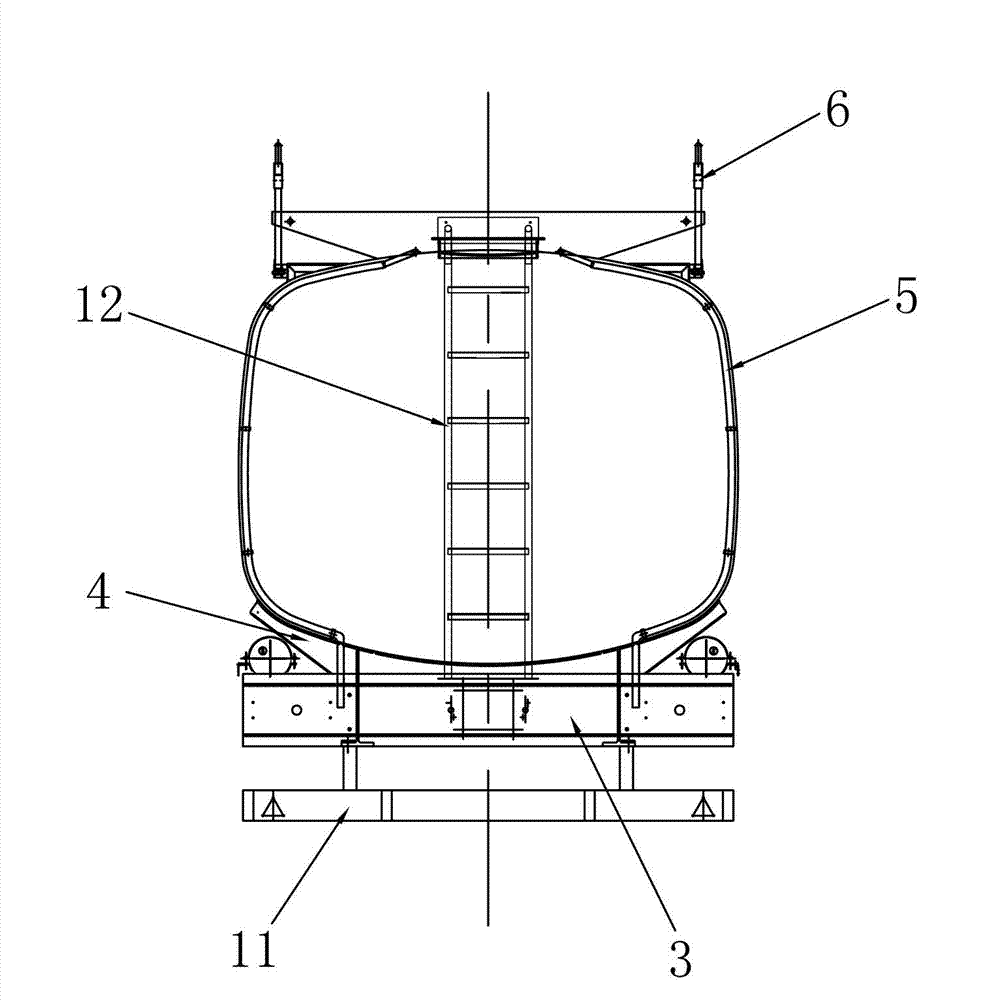

[0013] like figure 1 and figure 2 The shown first embodiment of the all-aluminum alloy tank trailer of the present invention includes a vehicle frame composed of a gooseneck 1, a longitudinal beam 2 and a cross beam 3, and the vehicle frame is sequentially provided with several laterally arranged tank body supports from front to back. Frame 4, the tank body support frame 4 is provided with tank body 5 along the front and rear directions, and the top of tank body 5 is provided with hurdle frame 6, and the bottom of the car frame is provided with supporting leg 7, side protection 8, toolbox 9, three A group of wheels 10 and a bumper 11, a climbing frame 12 is provided at the rear end of the tank body 5, wherein a gooseneck 1, a longitudinal beam 2, a beam 3, a tank support frame 4, a fence frame 6, legs 7, side protection 8, The tool box 9, the bumper 11 and the climbing frame 12 are all made of aluminum alloy, and the gooseneck 1, the longitudinal beam 2, the cross beam 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com