Resin transfer molding forming glue injection machine of continuous fiber reinforced PBT (polybutylece terephthalate) composite materials

A glue injection machine and glue injection technology, which is applied in the field of resin transfer molding glue injection machines and glue injection machines, can solve the problems of unfavorable promotion and application of continuous fiber reinforced PBT thermoplastic composite materials, achieve high accuracy and improve glue injection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

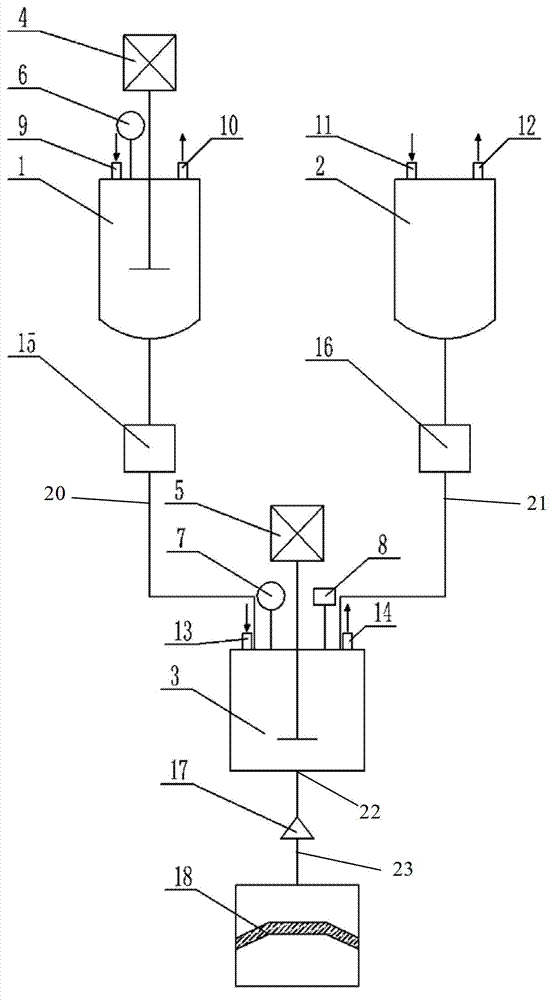

[0049]After extensive and in-depth research, the inventor of the present application accidentally designed an automatic resin transfer molding injection machine suitable for continuous fiber reinforced polybutylene terephthalate thermoplastic composites for the first time, including: A first tank to heat the monomer, a second tank to hold the catalyst, and a third tank. The monomer and the catalyst are transported to the third material tank through their respective metering devices to be mixed into the injection material; the injection material is injected into the mold through the discharge port and the pipeline at the bottom of the third material tank for molding, and the The volume of the third material tank is greater than the volume of the injection material that the mold can accommodate. The glue injection machine is capable of automatic metering and mixing, automatic glue injection, continuous process and high glue injection efficiency. On this basis, the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com