Iron-based low-alloy-steel powder for powder metallurgy and preparation method of iron-based low-alloy-steel powder

A low-alloy steel and powder metallurgy technology, applied in the field of iron-based metallurgical powder and its preparation, can solve the problems of mold wear and high alloy content, and achieve the effects of avoiding wear, small particle size range, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

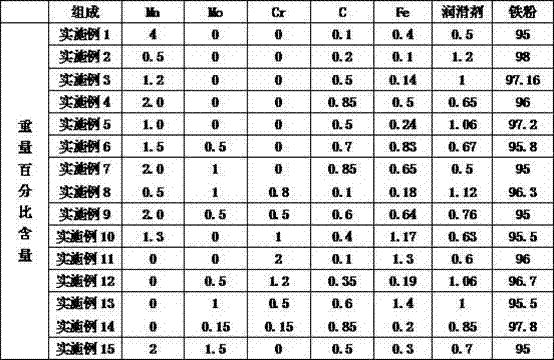

[0025] (1) Mix powder.

[0026] Grind ferromolybdenum powder, ferrochromium powder and ferromanganese powder according to the requirements of the above alloy powder preparation process, select part or all of them, add graphite and lubricant, mix them into iron powder, and mix them to form iron-based low-alloy steel powder. The composition of the alloy powder and the percentage by weight of the alloy powder, graphite, lubricant, and matrix iron powder in the total weight are shown in the table below, where Fe is the iron in the alloy powder.

[0027]

[0028] (2) Pressing and sintering:

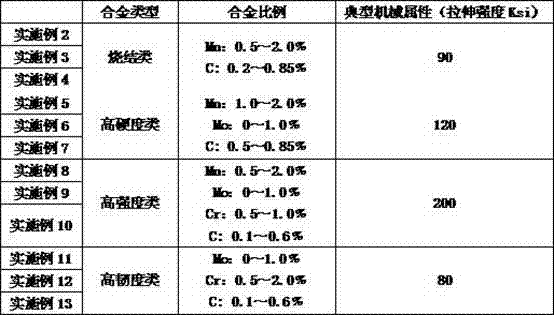

[0029] The various iron-based low-alloy steel powders prepared above are pressed with a certain press to form the green parts required, and then placed in a high-temperature reducing atmosphere sintering furnace (90% nitrogen, 10 hydrogen) for high-temperature sintering to form powder metallurgy parts. The mechanical properties of the prepared powder metallurgy parts are tested as shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com