Photoelectric device encapsulation and laser bonding temperature collection and control system and method

A technology of optoelectronic devices and control methods, applied in temperature control, control/regulation systems, non-electric variable control, etc., can solve the problem of lack of temperature acquisition and control modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

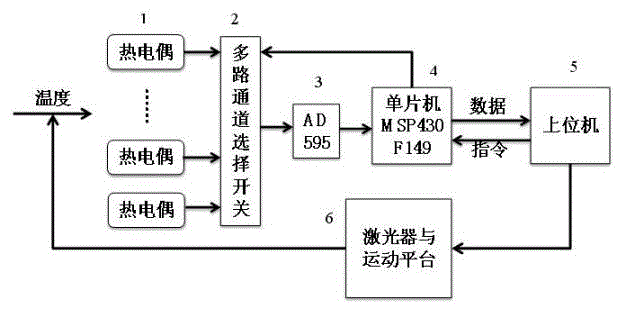

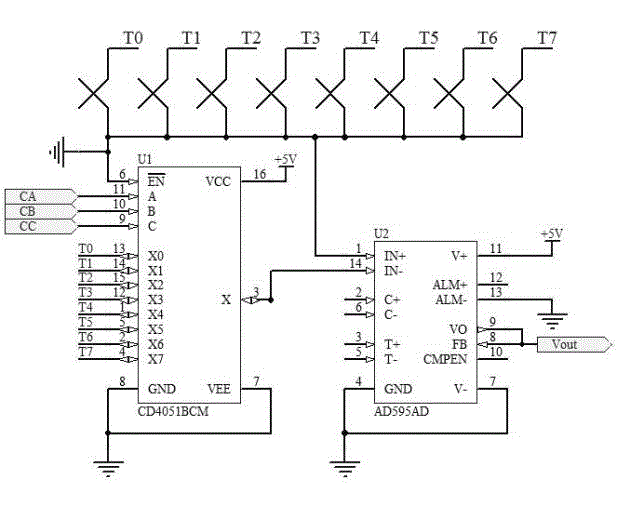

[0040] see figure 1, the photoelectric device packaging, laser bonding temperature acquisition and control system, including K-type thermocouple (1), analog switch CD4051 (2), temperature conversion chip AD595 (3), single-chip MSP430F149 (4), host computer (5 ), a laser and a motion platform (6), characterized in that: the K-type thermocouple (1) is connected to the single-chip microcomputer MSP430F149 (4) through the analog conversion switch CD4051 (2) through the temperature conversion chip AD595 (3); the single-chip microcomputer MSP430F149 (4) Connect and feedback control the analog switch CD4051 (2), and connect with the host computer (5), and the host computer (5) controls the bonding by controlling the laser and the motion platform (6) through its control program temperature.

Embodiment 2

[0042] see figure 1 , the optoelectronic device packaging, laser bonding temperature acquisition control system, including 8-way K-type thermocouple (1), multi-channel selection switch (2), AD595 chip (3), single-chip MSP430F149 (4), upper computer (5 ), laser and motion platform (6).

Embodiment 3

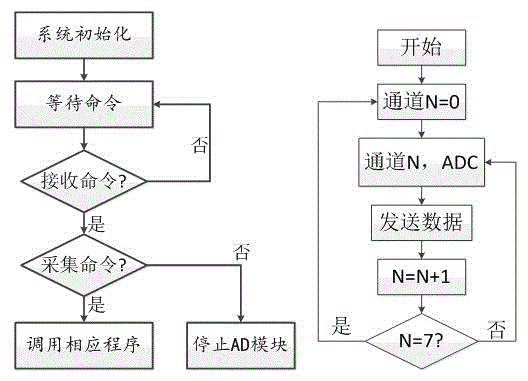

[0044] The optoelectronic device packaging, laser bonding temperature acquisition and control method, using the above system to operate, the operation steps:

[0045] 1. Place the OLED device to be packaged on the fixture platform for alignment and fixation;

[0046] 2. The upper computer (5) sends commands to run the laser and the motion platform (6) to make the laser head move according to the specified

[0047] Laser encapsulation of OLED devices;

[0048] 3. The upper computer and the lower computer carry out data transmission and communication, and send control commands from the upper computer to the unit.

[0049] In the MSP430F149 (4), the MSP430F149 (4) executes the command to control the multi-channel selection switch (2) to collect the temperature signals of the 8 thermocouples in sequence;

[0050] 4. Amplify and condition the collected temperature analog signal through AD595 (3) and then transmit it to

[0051] Input to the MSP430F149 (4) for analog-to-digital c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com