polyvinyl alcohol (PVA)/sodium carboxy methylated cellulose (Na-CMC) nanofiber, preparation method and application

A technology of sodium carboxymethyl cellulose and polyvinyl alcohol, which is applied in the fields of cellulose/protein conjugated rayon, fiber treatment, spinning solution preparation, etc., can solve the problems of small specific surface area of materials and limited application range, etc. Achieve the effects of simple preparation process, good biocompatibility and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Preparation of spinning solution: ① Weigh 0.9g of PVA into a dry Erlenmeyer flask, add 10.35mL of deionized water, and stir at 90°C for 2h. ②Weigh 0.1g Na-CMC into a dry Erlenmeyer flask, add 19.9mL deionized water, and stir at 70°C for 4h. ③Add the prepared Na-CMC solution into the prepared PVA solution, stir at 70°C for 4 hours, and prepare a uniform PVA / Na-CMC blend as the spinning solution.

[0021] 2. Electrospinning: Pour the configured solution into the glass spinneret, and start to apply voltage after the spinning solution flows out of the plastic nozzle. The spinning voltage is 8KV, and the receiving distance is 15cm. After electrospinning, a Na - Polyvinyl alcohol / sodium carboxymethylcellulose nanofibers with a CMC content of 10%.

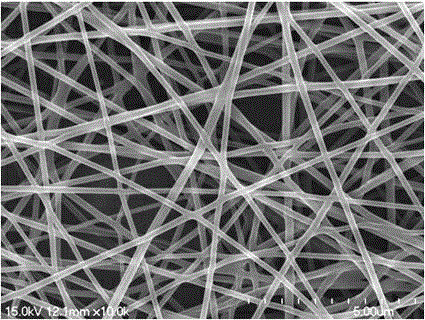

[0022] See attached figure 1 , it is the SEM photo of the PVA / Na-CMC fiber that the Na-CMC content provided by the present embodiment is 10%;

[0023] According to the method and process conditions of steps 1 and 2, PVA / Na...

Embodiment 2

[0027] 1. Preparation of spinning solution: ① Weigh 0.8 g of PVA into a dry Erlenmeyer flask, add 9.2 mL of deionized water, and stir at 90°C for 2 hours. ② Weigh 0.2g Na-CMC into a dry Erlenmeyer flask, add 9.8mL deionized water, and stir at 70°C for 4h. ③Add the prepared Na-CMC solution into the prepared PVA solution, stir at 70°C for 4 hours, and prepare a uniform PVA / Na-CMC blend as the spinning solution.

[0028] 2. Electrospinning: Pour the configured solution into the glass spinneret, and start to apply voltage after the spinning solution flows out of the plastic nozzle. The spinning voltage is 8KV, and the receiving distance is 15cm. After electrospinning, a Na - Polyvinyl alcohol / sodium carboxymethylcellulose nanofibers with a CMC content of 20%.

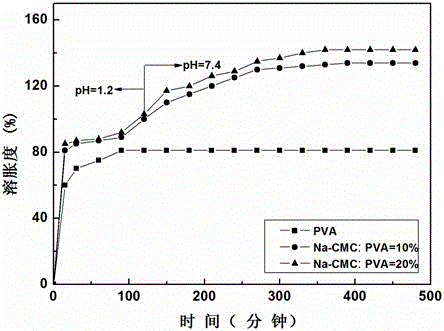

[0029] pH sensitivity test: Weigh 15 mg of the prepared polyvinyl alcohol / sodium carboxymethylcellulose nanofibers, first place them in HCl (pH = 1.2) for 2 hours, and then place them in a buffer solution (PBS, pH = 7.4). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com