Polyoxy propane diethylene glycol borate polymer, preparation method thereof and environment-friendly water-soluble anti-rust quenching liquid prepared with the polymer

A technology of polyoxypropylene diethylene glycol borate and diethylene glycol borate, which is applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc. Not hard and other problems, to achieve the effect of good anti-rust effect, low cost of use and deep hardened layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh 25g of potassium borate and 3g of potassium sorbate and add them into 422g of water and stir, add 550g of polyoxypropylene diethylene glycol borate polymer B and stir for 2 hours at the same time to prepare the environment-friendly water-soluble rust-proof quenching liquid sample of the present invention.

[0050] The 10% aqueous solution of this sample was subjected to a damp heat test for 7 days according to the test method of GB / T2361, and the result was grade 1, meeting the standard.

[0051] Typical cooling rate characteristic curves of different concentrations of this sample's environment-friendly water-soluble anti-rust quenching liquid and tap water are as follows: figure 1 As shown (tested by IVF cooling rate tester in accordance with ISO 9950 standard). From figure 1 It can be seen that the cooling rate of the environment-friendly water-soluble anti-rust quenching liquid of the present invention is significantly lower than that of water in the convectio...

Embodiment 2

[0053] The quenching material is: 5CrMnMo, the size is: 760X310X280 die steel, the surface hardness after heat treatment is required to be 40-45HRC (the hardness difference is within 3HRC), and no rust can occur within 15 days after treatment. Quenching process: Preheat once at 500-550°C, heat at 830-850°C, temper twice at 450-480°C, and hold for 2 hours. Quenching tank volume is 15m 3 , can hold quenching medium 10-15 tons.

[0054] Add 500 kg of polyoxypropylene diethylene glycol borate polymer B into 473 kg of water to which 23 kg of potassium borate and 4 kg of potassium sorbate have been added and stir for 2.5 hours to prepare an environmentally friendly water-soluble anti-rust quenching liquid. The prepared environment-friendly water-soluble anti-rust quenching liquid is added to the quenching tank already equipped with 10 tons of water, and the pump is circulated to stir, and the quenching process also uses the pump to circulate.

[0055] Quality inspection results: A...

Embodiment 3

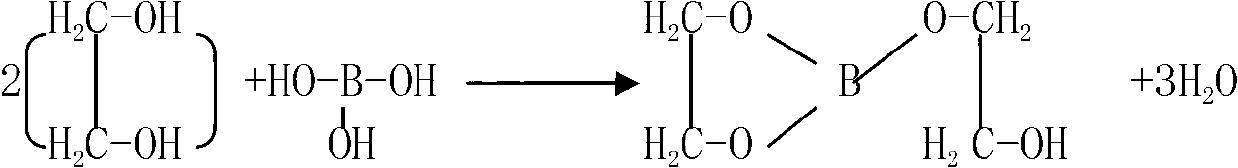

[0057] Step 1. Feed 124.136kg (2000mol) of ethylene glycol and 61.83kg (1000mol) of boric acid into the reaction kettle, fill it with nitrogen protection, stir and heat to about 175°C, keep it warm for 4.5 hours, pass in toluene and azeotrope the mixed solution, Diethylene glycol borate A138kg (1000mol) was obtained by distilling off the azeotrope of water and toluene.

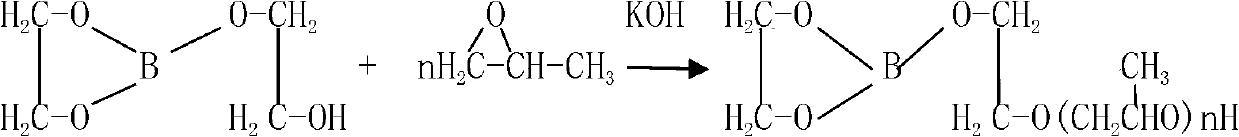

[0058] Step 2. Add 138 kg (1000 mol) of diethylene glycol borate A and 10 kg of potassium hydroxide obtained in step 1 into a polymerization tank cooled by ice-salt water circulation at about 0°C and stir, then feed nitrogen into the polymerization tank to switch The air in the kettle, when the nitrogen in the polymerization kettle maintains a positive pressure, use the nitrogen feed tank to push 1742.4kg (30000mol) propylene oxide into the polymerization kettle, while stirring and raising the temperature to 100°C, and adjusting the pressure to 0.3MPa. After 16 hours of polymerization, Extrude the polymer in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com