Oily water-soluble quenching liquid and preparation method thereof

A water-soluble, quenching liquid technology, applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of fire hazards, easy to pollute the environment, difficult to handle waste residues, etc., to eliminate fire hazards, wide application range, low cost of use low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

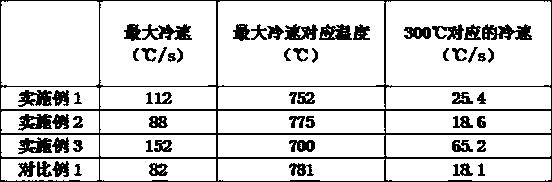

Examples

Embodiment 1

[0014] The oil-like water-soluble quenching liquid of the present invention includes 10% polyvinylpyrrolidone, 5% complex amine, 2% dicarboxylic acid, 1% boric acid, 0.5% defoamer, 1% sodium nitrite, and the rest is deionized water .

[0015] The preparation method of the above-mentioned oily water-soluble quenching liquid is as follows: dissolve the complex amine, add dicarboxylic acid, mix evenly at a temperature of 40-70°C, continue to add sodium nitrite, and then put in polyvinylpyrrolidone and defoamer in turn , stir and mix evenly at 100 rpm, and control the pH of the entire mixed liquid system at 9.5.

Embodiment 2

[0017] The oil-like water-soluble quenching liquid of the present invention comprises 15% of polyvinylpyrrolidone, 10% of compound amine, 2% of dicarboxylic acid, 1.5% of boric acid, 0.5% of defoamer, 1.2% of sodium nitrite, and the rest is deionized water .

[0018] The preparation method of the above-mentioned oily water-soluble quenching liquid is as follows: dissolve the complex amine, add dicarboxylic acid, mix evenly at a temperature of 40-70°C, continue to add sodium nitrite, and then put in polyvinylpyrrolidone and defoamer in turn , stirred and mixed evenly at 150 rpm, and the pH of the entire mixed liquid system was controlled at 9.0.

Embodiment 3

[0020] The oil-like water-soluble quenching liquid of the present invention includes 5% polyvinylpyrrolidone, 5% complex amine, 1.5% dicarboxylic acid, 0.7% boric acid, 0.5% defoamer, 1% sodium nitrite, and the rest is deionized water .

[0021] The preparation method of the above-mentioned oily water-soluble quenching liquid is as follows: dissolve the complex amine, add dicarboxylic acid, mix evenly at a temperature of 40-70°C, continue to add sodium nitrite, and then put in polyvinylpyrrolidone and defoamer in turn , stirred and mixed evenly at a rotating speed of 50 rpm, and the pH of the entire mixed liquid system was controlled at 9.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com