High-strength polyurethane film for laminated glass and preparation method thereof

A technology of polyurethane film and laminated glass is applied in the preparation of high-strength polyurethane film. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

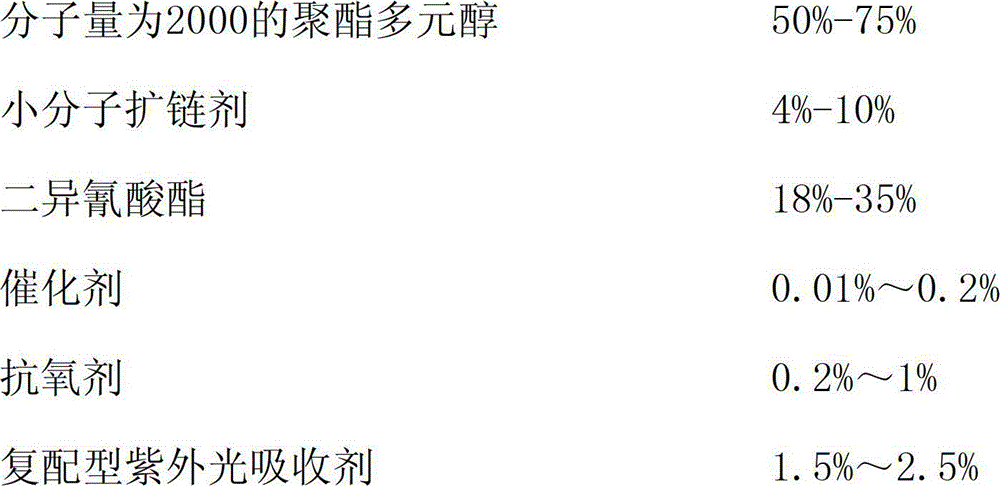

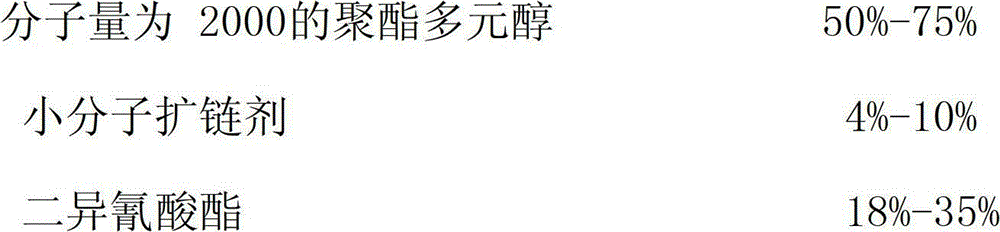

Method used

Image

Examples

Embodiment 1

[0022] Step 1. Vacuum dehydrate 140kg of polyester polyol (molecular weight: 2000) and 9kg of small molecule chain extender at 100-120°C for about 2 hours to make the moisture content less than 0.05%.

[0023] Wherein: polyester polyol is polybutylene adipate diol prepared by condensation of adipic acid and 1,4-butanediol; its reaction chemical equation is as follows:

[0024]

[0025] Among them, nHOOC-R-COOH corresponds to HOOC-(CH2)4-COOH (adipic acid)

[0026] HO-R'-OH corresponds to HO-CH2CH2CH2CH2-OH (1,4-butanediol)

[0027] Step 2, the polyester polyol described in step 1, the small molecule chain extender and 40kg diphenylmethane-4,4'-diisocyanate (MDI), 0.02kg catalyst (0.01kg dibutyltin dilaurate and 0.01kg triethylenetriamine), 1.0kg antioxidant, 4kg compound UV absorber (1.5kg di(2,2,6,6-tetramethyl-4-piperidinyl) sebacate and 2.5kg 2-(2-hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole) were added to the twin-screw extruder in parts by weight (screw spe...

Embodiment 2

[0030] Step 1. Vacuum dehydrate 134kg of polyester polyol (molecular weight: 2000) and 15kg of small molecule chain extender at 100-120°C for about 2 hours to make the moisture content less than 0.05%.

[0031] Step 2, the polyester polyol described in step 1, the small molecule chain extender and 51.5kg diphenylmethane-4,4'-diisocyanate (MDI), 0.02kg catalyst (0.01kg dibutyltin dilaurate and 0.01kg triethylenetriamine), 1.0kg antioxidant, 4kg compound UV absorber (1.5kg di(2,2,6,6-tetramethyl-4-piperidinyl) sebacic acid Esters and 2.5kg 2-(2-hydroxyl-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole) were added to the twin-screw extruder in parts by weight (screw speed between 70-90rpm ) to mix and react. The temperature of the feeding section of the extruder is controlled at 100-140°C, the temperature of the reaction zone is controlled at 150-200°C, the temperature of the extrusion zone is controlled at 160-210°C, the reaction time is 5-10 minutes, and finally the organic head...

Embodiment 3

[0034]Step 1. Vacuum dehydrate 132kg of polyester polyol (molecular weight: 2000) and 14kg of small molecule chain extender at 100-120°C for about 2 hours to make the moisture content less than 0.05%.

[0035] Step 2, the polyester polyol described in step 1, small molecule chain extender and 36kg1,6-hexamethylene diisocyanate (HDI), 0.02kg catalyst (0.01kg dibutyltin dilaurate and 0.01kg triethylene Triamine), 1.0kg antioxidant, 4.0kg complex UV absorber (1.5kg di(2,2,6,6-tetramethyl-4-piperidinyl) sebacate and 2.5kg 2 -(2-Hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole) is added in parts by weight into a twin-screw extruder (screw speed is between 70-90rpm) for mixing and reaction. The temperature of the feeding section of the extruder is controlled at 100-140°C, the temperature of the reaction zone is controlled at 150-200°C, the temperature of the extrusion zone is controlled at 160-210°C, the reaction time is 5-10 minutes, and finally the organic head extrudes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com