Method for machining stereoscopic patterns of aluminum plate surface

A technology of three-dimensional pattern and processing method, which is applied in decorative arts, embossed ornaments and other directions to achieve the effect of improving flexibility, improving aesthetics and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

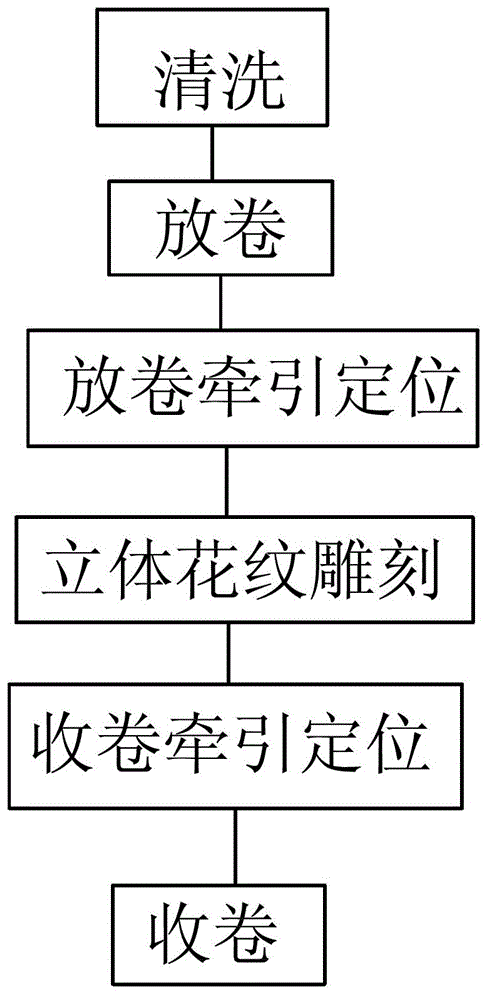

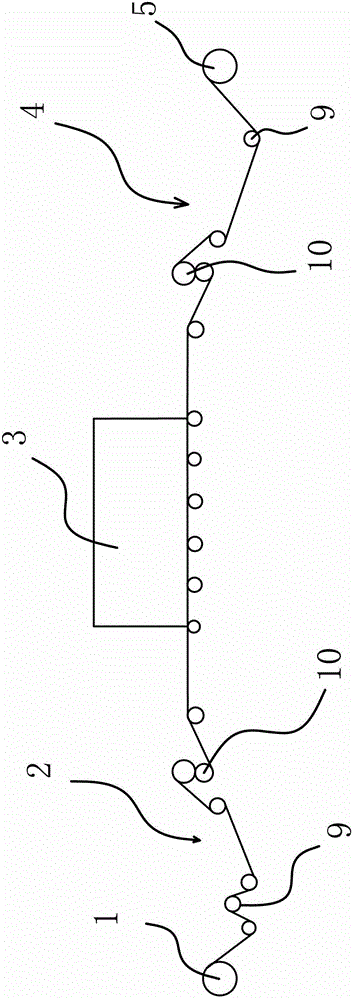

[0032] like figure 1 , figure 2 and image 3 As shown, the processing method of the three-dimensional pattern on the surface of the aluminum plate includes the following steps:

[0033] a. Cleaning: remove oil stains and impurities on the surface of the aluminum plate 11 by cleaning; the cleaning in process a includes sequentially treating the surface of the aluminum plate 11 with alkali washing, pickling and passivation. Through the treatment of the above several steps, basically all the oil stains and impurities on the surface of the aluminum plate 11 are removed.

[0034] b. Unwinding: Place the aluminum coil wound into a cylindrical shape by the aluminum plate 11 on the unwinding mechanism 1. In this embodiment, the size of the aluminum coil is generally 0.12*1270mm, and the unwinding tension is determined according to the weight of the aluminum coil and the type of pattern The preset value of the unwinding mechanism 1 is 70-80N, and the unwinding tension of the unwind...

Embodiment 2

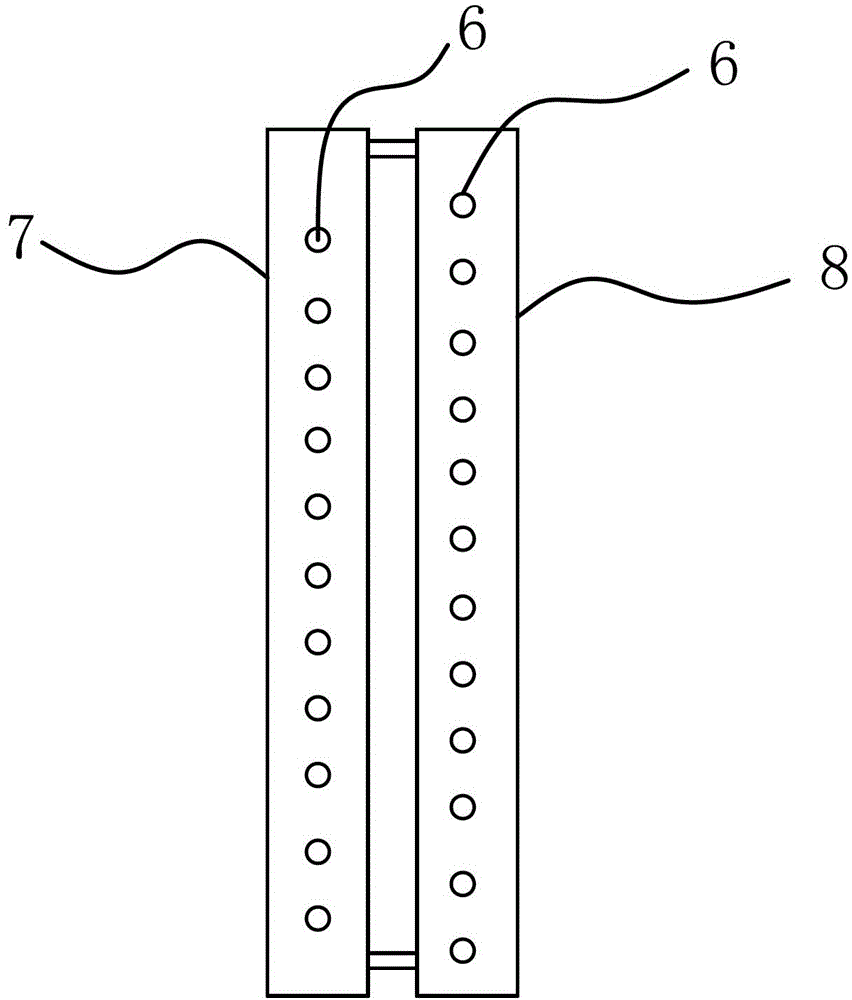

[0041] The general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the CNC grinding machine device 3 includes several grinding heads 6, and each grinding head 6 is connected with a servo motor for driving. The distribution mode of the grinding heads 6 is disc distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com