Scanning type object surface three-dimensional shape measurement method and device

A technology of three-dimensional topography and object surface, which is used in measuring devices, optical devices, instruments, etc. It can solve the problems of scanning speed limitation, inability to achieve large-scale high-speed scanning at the same time, and small scanning range. Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

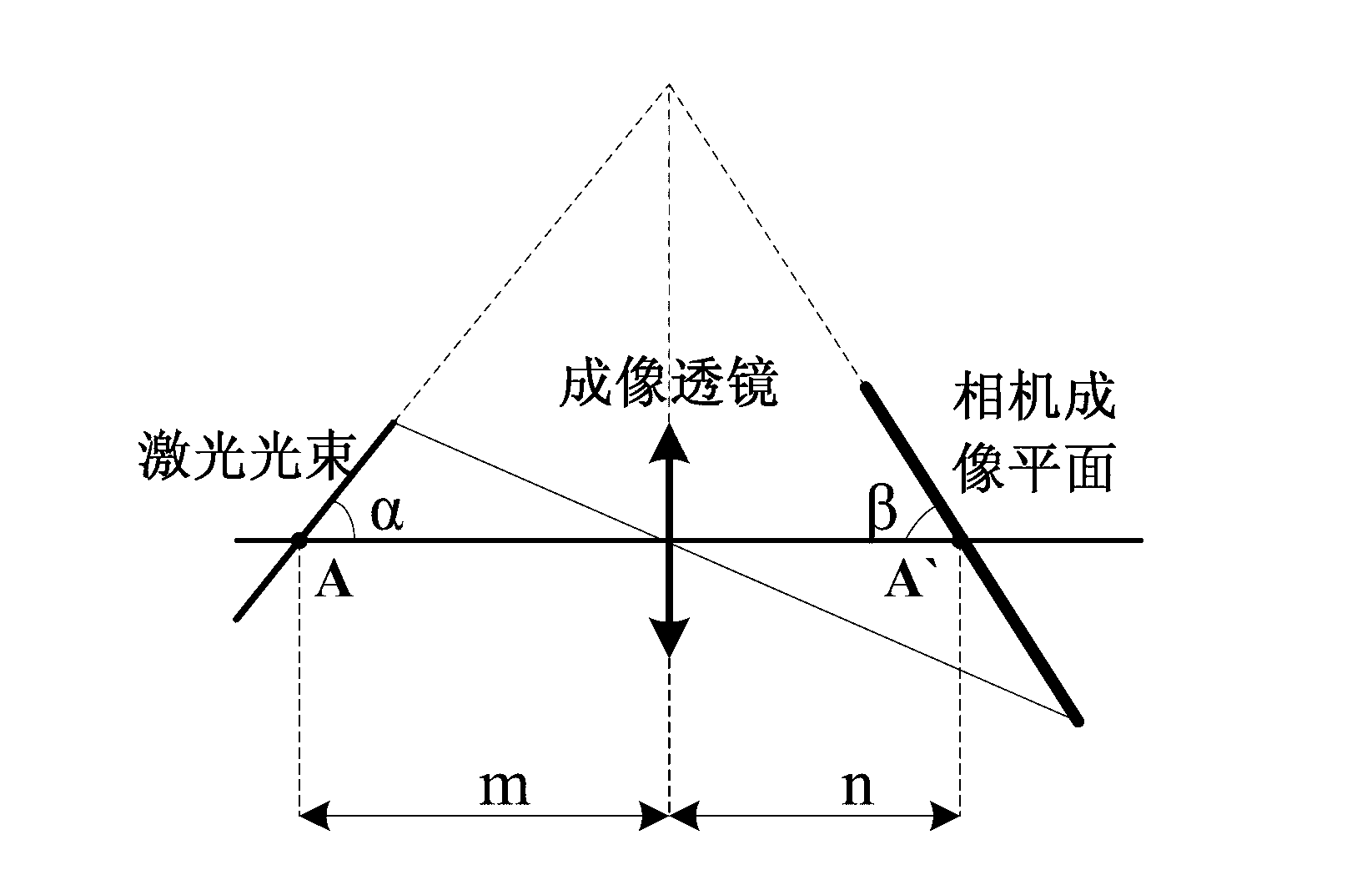

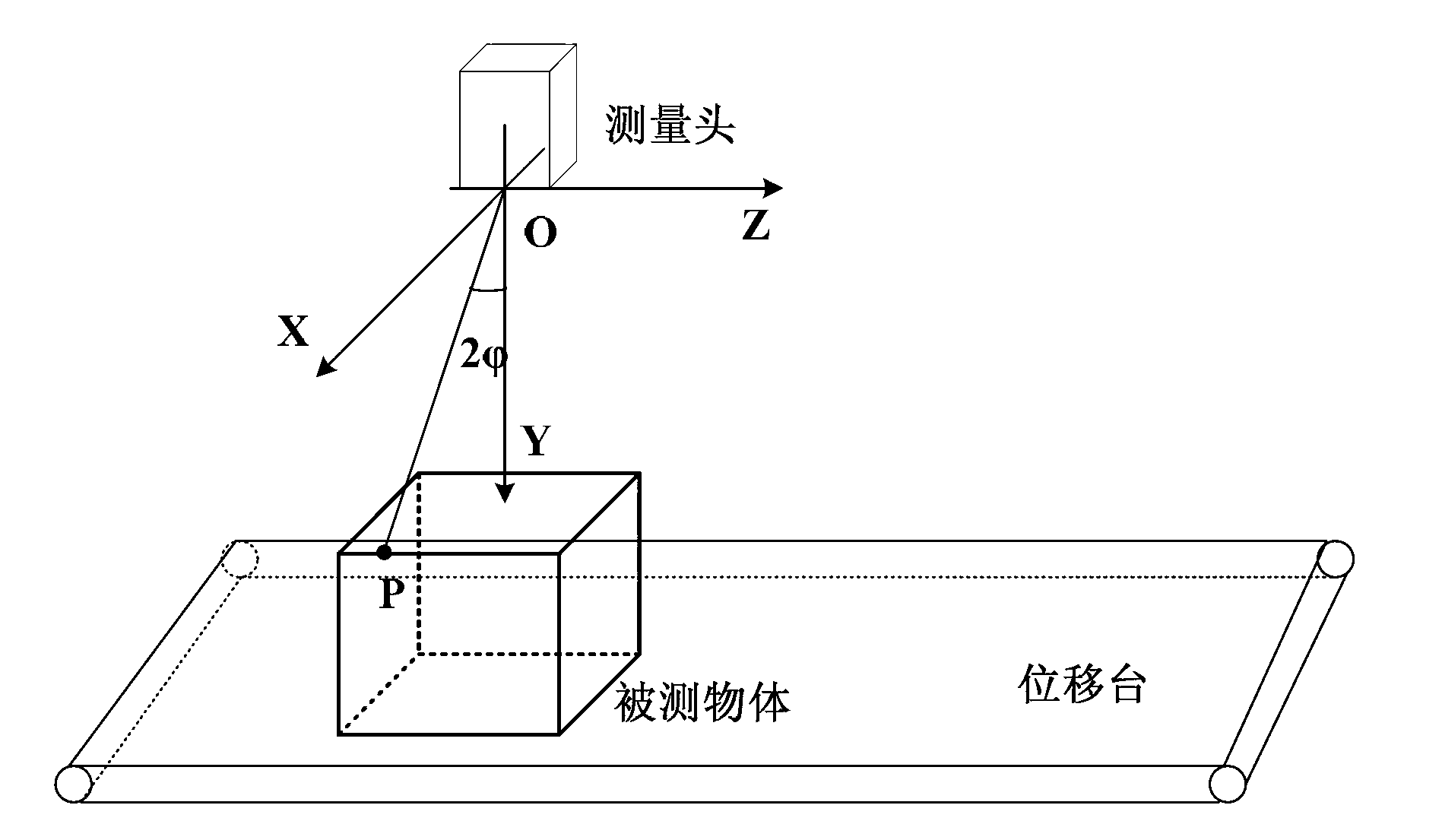

[0032] The specific implementation of the measuring device will be described below with reference to the accompanying drawings.

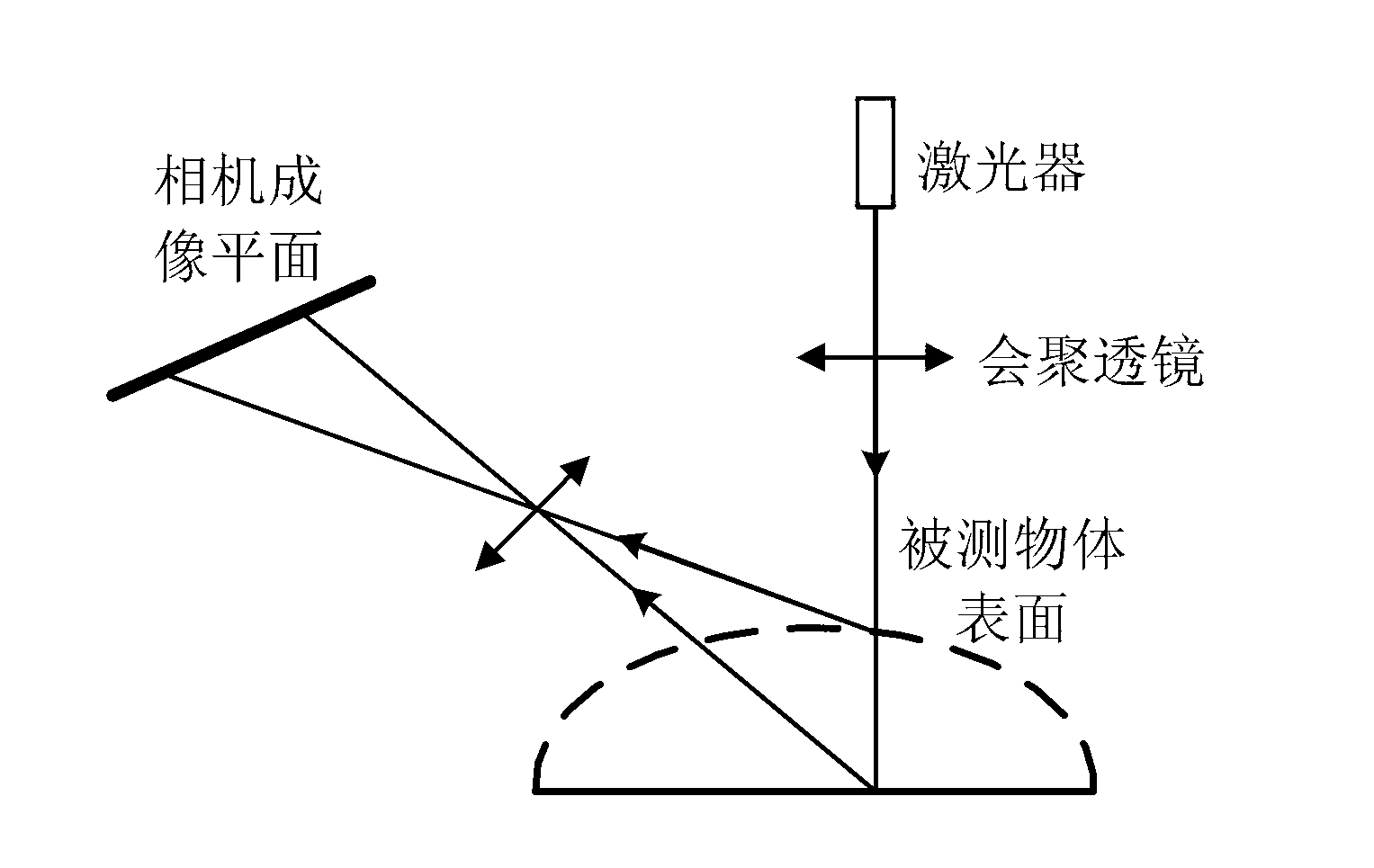

[0033] 1) if Figure 4 As shown, the present invention is a scanning type object surface three-dimensional shape measuring device, which is composed of a measuring head, a computer and a displacement platform, and the positional connection relationship between them is that the computer is connected to the measuring head and the displacement platform respectively through data lines.

[0034] The measuring head is composed of a laser, a scanning device and an imaging device. The positional connection relationship between them is that the laser and the imaging device maintain a predetermined angle and are placed on the same side of the scanning device.

[0035] The laser is a visible light semiconductor laser. The scanning device is composed of a motor, a multi-faceted rotating mirror, and an angle encoder; the relationship between them is: the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com