Semi-continuous preparation method of poly-p-phenylene benzobisoxazazole polymer

A technology of benzobisoxazole and polyparaphenylene, applied in the direction of single-component synthetic polymer rayon, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of inability to obtain high molecular weight polymers and batch-to-batch polymerization Large differences in material properties, difficult material transportation and transfer, etc., to achieve the effect of increasing surface renewal ability, ensuring performance and quality, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

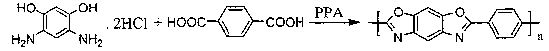

[0027] A semi-continuous preparation method of poly-p-phenylene benzobisoxazole polymer, comprising the following processing steps:

[0028] A. Add terephthalic acid, 4,6-diaminoresorcinol hydrochloride, polyphosphoric acid and phosphorus pentoxide to the kneader with the discharge screw conveying device under the belt to remove hydrogen chloride and material Mixing, and then the mixture is transported to the mixing kettle through the lower discharge screw conveying device of the kneader;

[0029] B. Mix and defoam the mixture delivered to the mixing tank at 120° C. for 1 hour, and then deliver it to a filter for conventional filtration in the field;

[0030] C, after the mixture is filtered, it directly enters more than 2 screw extruders in series for polymerization to obtain the product of the present invention i.e. the described polyparaphenylene benzobisoxazole polymer; the polymerization temperature in the screw extruder The control is 130°C.

Embodiment 2

[0032] A semi-continuous preparation method of poly-p-phenylene benzobisoxazole polymer, comprising the following processing steps:

[0033] A. Add terephthalic acid, 4,6-diaminoresorcinol hydrochloride, polyphosphoric acid and phosphorus pentoxide to the kneader with the discharge screw conveying device under the belt to remove hydrogen chloride and material Mixing, and then the mixture is transported to the mixing kettle through the lower discharge screw conveying device of the kneader;

[0034] B. Mix and defoam the mixture delivered to the mixing tank at 180°C for 10 hours, and then deliver it to a filter for conventional filtration in this field;

[0035] C, after the mixture is filtered, it directly enters more than 2 screw extruders in series for polymerization to obtain the product of the present invention i.e. the described polyparaphenylene benzobisoxazole polymer; the polymerization temperature in the screw extruder The control is 220°C.

Embodiment 3

[0037] A semi-continuous preparation method of poly-p-phenylene benzobisoxazole polymer, comprising the following processing steps:

[0038] A. Add terephthalic acid, 4,6-diaminoresorcinol hydrochloride, polyphosphoric acid and phosphorus pentoxide to the kneader with the discharge screw conveying device under the belt to remove hydrogen chloride and material Mixing, and then the mixture is transported to the mixing kettle through the lower discharge screw conveying device of the kneader;

[0039] B. Mix and defoam the mixture delivered to the mixing tank at 150° C. for 5.5 hours, and then deliver it to a filter for conventional filtration in this field;

[0040] C, after the mixture is filtered, it directly enters more than 2 screw extruders in series for polymerization to obtain the product of the present invention i.e. the described polyparaphenylene benzobisoxazole polymer; the polymerization temperature in the screw extruder The control is 175°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com