Multi-functional efficient oil scavenge polymer and preparation method of raw material graft modification starch thereof

A technology of oil displacement polymer and graft modification, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve the problem of low viscosity retention rate, low water absorption of monomer graft modified starch, and reduced interface Tension and other issues, to achieve good biodegradability, excellent interface activity, and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

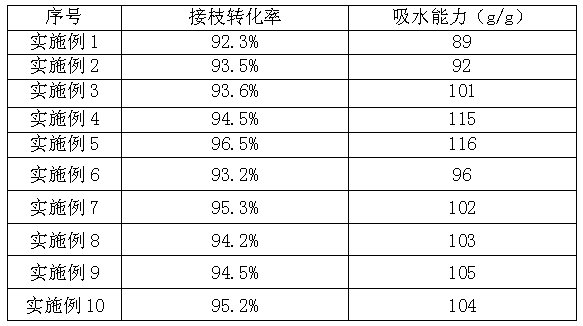

Examples

Embodiment 1

[0020] a. Weigh 50g of water and put it into a four-necked flask, add 25g of acrylonitrile starch, when the temperature rises to 55°C, stir to dissolve the starch, add 3.5g of potassium chloride, 5g of 20% sodium hydroxide solution, stir evenly, and use drops Slowly drop 35g of dodecane chloride into the liquid funnel, raise the temperature to 80°C, finish the reaction after 6 hours of reaction, and generate an intermediate for use.

[0021] b. Weigh 50g of intermediate 1 into a polymerization reaction vessel, add 35g of deionized water, stir evenly, heat up to 80°C, pass nitrogen gas for 30 minutes, cool down to 50°C, add 0.02g of initiator cerium ammonium nitrate, stir After 10 minutes, 10 g of acrylic acid was added, and after reacting for 3 hours, the crude product was extracted with ethanol to obtain monomer grafted modified starch.

Embodiment 2

[0023] a. Weigh 60g of water and put it into a four-necked flask, add 30g of acrylonitrile starch, when the temperature rises to 50°C, stir to dissolve the starch, add 3g of 20% sodium hydroxide solution, stir evenly, slowly dissolve 30g of acrylonitrile starch with a dropping funnel Chlorododecane was added dropwise, and the temperature was raised to 85°C. After 6 hours of reaction, the reaction was terminated, and an intermediate was generated for use.

[0024] b. Weigh 35g of intermediate 1 into a polymerization reaction vessel, add 35g of deionized water, stir evenly, heat up to 80°C, pass nitrogen gas for 30 minutes, cool down to 50°C, add 0.03g of initiator cerium ammonium nitrate, stir After 10 minutes, 20 g of acrylic acid was added, and after reacting for 3 hours, the crude product was extracted with ethanol to obtain monomer grafted modified starch.

Embodiment 3

[0026] a. Weigh 70g of water and put it into a four-neck flask, add 35g of acrylonitrile starch, when the temperature rises to 60°C, stir to dissolve the starch, add 2.5g of potassium chloride, 4g of 20% sodium hydroxide solution, stir evenly, and use drops Slowly drop 25g of dodecane chloride into the liquid funnel, raise the temperature to 90°C, finish the reaction after 6 hours of reaction, and generate an intermediate for use.

[0027] b. Weigh 40g of intermediate 1 into a polymerization reaction vessel, add 35g of deionized water, stir evenly, heat up to 80°C, pass nitrogen gas for 30 minutes, cool down to 50°C, add 0.035g of initiator cerium ammonium nitrate, and stir After 10 minutes, 25 g of acrylic acid was added, and after reacting for 3 hours, the crude product was extracted with ethanol to obtain monomer grafted modified starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com