Nano silver paste for chip mounting and method for preparing nano silver paste

A nano-silver paste, chip mounting technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for material and surface science, can solve problems such as large heat generation, affecting light output efficiency and service life, and achieve heat dissipation. problems, suitable for automated production, the effect of reducing the sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

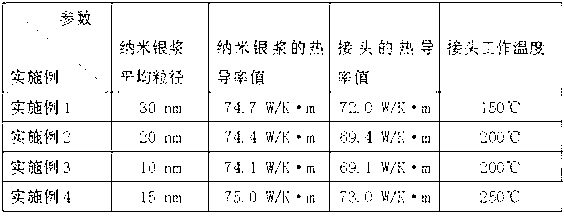

Examples

Embodiment 1

[0026] First, weigh 6mL, 2mol / L sodium citrate at a speed of 20mL / min, and add it dropwise to 2.5mL, 1mol / L silver nitrate solution, while applying 400r / min mechanical stirring. After the solution was added dropwise, the stirring was continued for 5 min.

[0027] The nano-silver solution obtained by the chemical reaction was centrifuged at a speed of 3500 r / min for 10 min. After the centrifugation is completed, pour off the mixed solution in the upper layer to obtain the silver nanoparticles precipitated in the lower layer. After the nano-silver particles were washed with deionized water, they were flocculated with 50 mL, 1 mol / L potassium nitrate solution and centrifuged again.

[0028] Repeat for three times to obtain the final nano silver paste. The nano-silver paste is applied to the surface of the interconnection between the chip and the substrate, heated with a hot-air workbench, the sintering temperature is set to 150°C, and the sintering time is 10 minutes to form a ...

Embodiment 2

[0030] First, mix 2.5mL, 1mol / L sodium citrate with 3.5mL, 2mol / L sodium borohydride solution, add dropwise to 3mL, 0.5mol / L silver nitrate solution at a speed of 10mL / min, At the same time, 1 mL of 0.3 mol / L polyvinylpyrrolidone solution was added dropwise, and mechanical stirring was applied at 500 r / min. After the solution was added dropwise, the stirring was continued for 5 min.

[0031] The obtained nano-silver solution was centrifuged at a speed of 5000r / min for 5min. After the centrifugation is completed, pour off the mixed solution in the upper layer to obtain the nano-silver slurry precipitated in the lower layer. After cleaning the nano-silver paste with deionized water, flocculate with 50 mL, 1 mol / L sodium citrate solution, and centrifuge again.

[0032] Repeat for three times to obtain the final nano silver paste. The nano-silver paste is applied to the surface of the interconnection between the chip and the substrate, heated with a hot air workbench, the sinte...

Embodiment 3

[0034] First, weigh 3.5mL, 1.5mol / L sodium citrate dihydrate and mix with 2.5mL, 1mol / L ferrous sulfate solution, and add dropwise to 2.5mL, 0.5mol / L silver nitrate solution at a speed of 20mL / min. In the solution, a mechanical stirring of 300r / min was applied. After the solution was added dropwise, the stirring was continued for 5 min.

[0035] The obtained nano-silver solution was centrifuged at a speed of 5000r / min for 5min. After the centrifugation is completed, pour off the mixed solution in the upper layer to obtain the nano-silver slurry precipitated in the lower layer. After cleaning the nano-silver paste with deionized water, flocculate with 50 mL, 1.5 mol / L sodium citrate solution, and centrifuge again.

[0036] Repeat for three times to obtain the final nano silver paste. The nano-silver paste is applied to the surface of the interconnection between the chip and the substrate, heated with a hot air workbench, the sintering temperature is 200°C, and the sintering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com