Antibiosis perfuming type air filter

An air filter and filter technology, applied in the direction of dispersed particle filtration, gasification substances, chemical instruments and methods, etc., can solve the problems of organic antibacterial agent safety hazards, secondary pollution, and difficulty in ensuring long-term effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

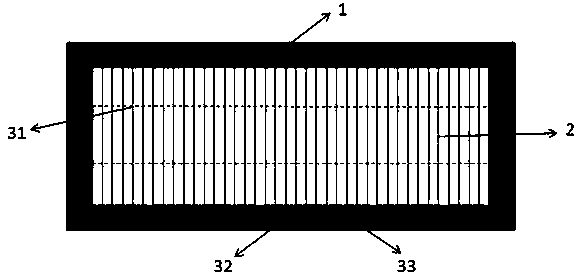

[0022] In this example, if figure 1 As shown, an antibacterial and scented air filter has a plate structure as a whole, and the outer plastic part 1 is made of PP material; the discounted antibacterial filter element 2 is made of a single layer with a weight of 120g / m 2 The antibacterial impregnated non-woven fabric is prepared at a discount. The antibacterial finishing method is the spraying method in the finishing process. The antibacterial agent adopts nano-silver liquid antibacterial agent, and the amount of antibacterial agent added is 2.5% of the mass of the impregnated non-woven fabric; The carrier is a hot-melt adhesive with a melting point of 120°C, which is loaded near the air outlet of the filter. The type of fragrance is a natural rose-flavored type, and the amount added is 30% of the mass of the hot-melt adhesive. The above-mentioned hot-melt adhesive and natural rose-flavored Flavoring adhesives 31, 32, 33 formed by uniformly mixing flavors are distributed on the...

specific Embodiment 2

[0023] In this embodiment, an antibacterial and scented air filter has a cylindrical structure as a whole, and the external plastic parts are made of PS material; the discounted antibacterial filter element is made of two layers of 2 A layer of impregnated non-woven fabric with a weight of 18g / m 2 The antibacterial PP melt-blown non-woven fabric is prepared at a discount. The antibacterial finishing method is realized by adding PP antibacterial masterbatch in the early stage. The antibacterial agent belongs to the nano-silver powder antibacterial agent. The amount of antibacterial agent added is 3 times the mass of the impregnated non-woven fabric %; the flavoring carrier is a two-component foaming polyurethane glue with a hardness of 20Shore A, which is filled in the tank of the cartridge filter. 15%.

specific Embodiment 3

[0024] In this embodiment, an antibacterial fragrance air filter has a plate structure as a whole, and the outer plastic parts are made of ABS material; the discounted antibacterial filter element is made of two layers of 2 A layer of impregnated non-woven fabric with a weight of 30g / m 2 The antibacterial needle-punched non-woven fabric is prepared at a discount. The antibacterial finishing method is the impregnation method in the finishing process. The antibacterial agent uses natural antibacterial ingredients extracted from licorice, honeysuckle and Artemisia annua as the antibacterial finishing agent. The amount of antibacterial agent added is 5% of the mass of impregnated non-woven fabric; the fragrance carrier is a two-component non-foaming polyurethane glue with a hardness of 50 Shore A, which is loaded near the air outlet of the filter. The type of essence is oil-soluble microporous capsule essence, and the fragrance type is lavender. The amount added is 20% of the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com