Slip ring and lead fixing structure for inverted dynamic braking wound rotor motor

A winding motor and energy-consumption braking technology, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the design problems of winding motor slip ring and lead wire fixing, etc., and achieves ingenious structural concept, obvious effect and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

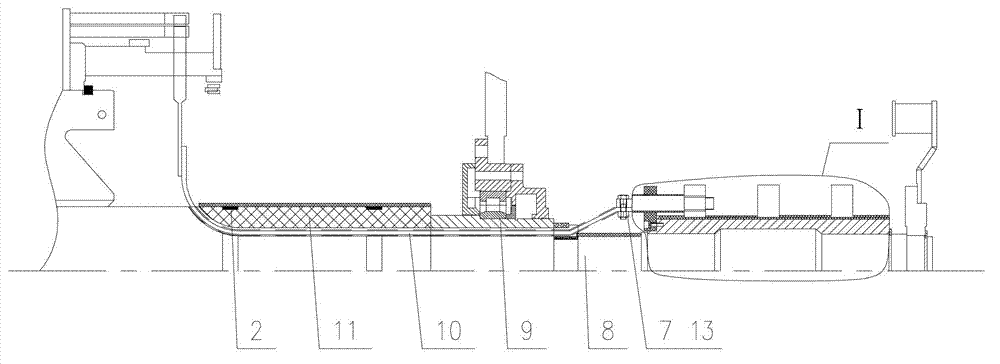

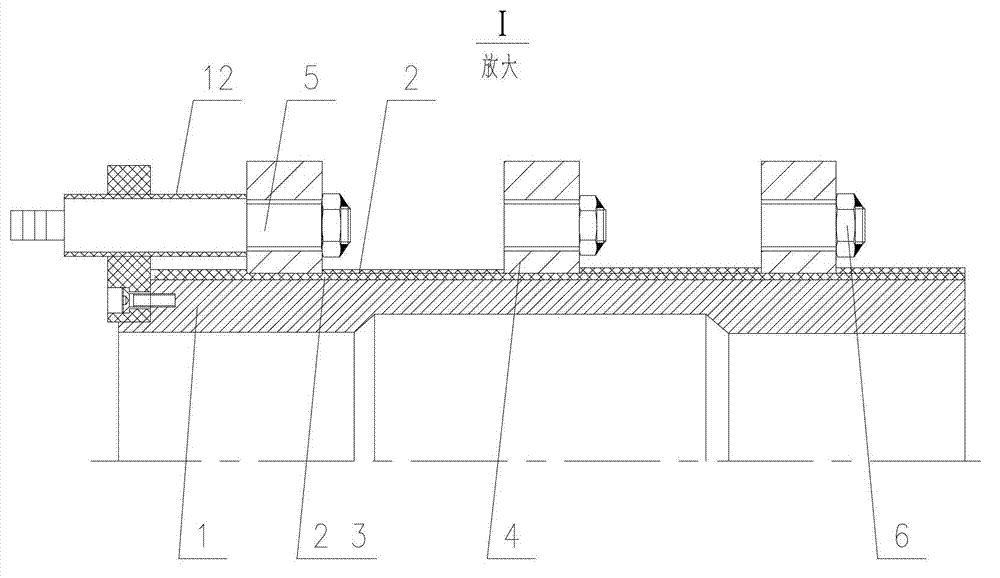

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , figure 2 As shown, the present invention includes slip ring bushing 1, latitude-free tape 2, polyesterimide film 3, conductive ring 4, conductive rod 5, flat nut 6, bolt 7, shaft 8, steel sleeve 9, lead wire conductive row 10 , Epoxy plate spacer 11, mica tape 12, stop washer 13.

[0021] The slip ring insulation cancels the traditional structure of "epoxy board wrapping or epoxy glass cloth pipe". The outer surface of the slip ring bushing 1 is knurled. The polyesterimide film 3 is flat-wrapped, and then the latitude-free tape 2 is continued to be bound. After the latitude-free tape 2 is cured, the outer circle of the car is guaranteed to ensure the size and shape tolerance, and then the conductive rings 4 are covered, and the latitude-free tape 2 is used for binding between each conductive ring 4. And dip the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com