Material in-situ turning-over platform

A platform and in-situ technology, applied in the field of automation, can solve the problems of large space occupation, low positioning accuracy, material falling, etc., and achieve the effect of reducing the use of space, reducing production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

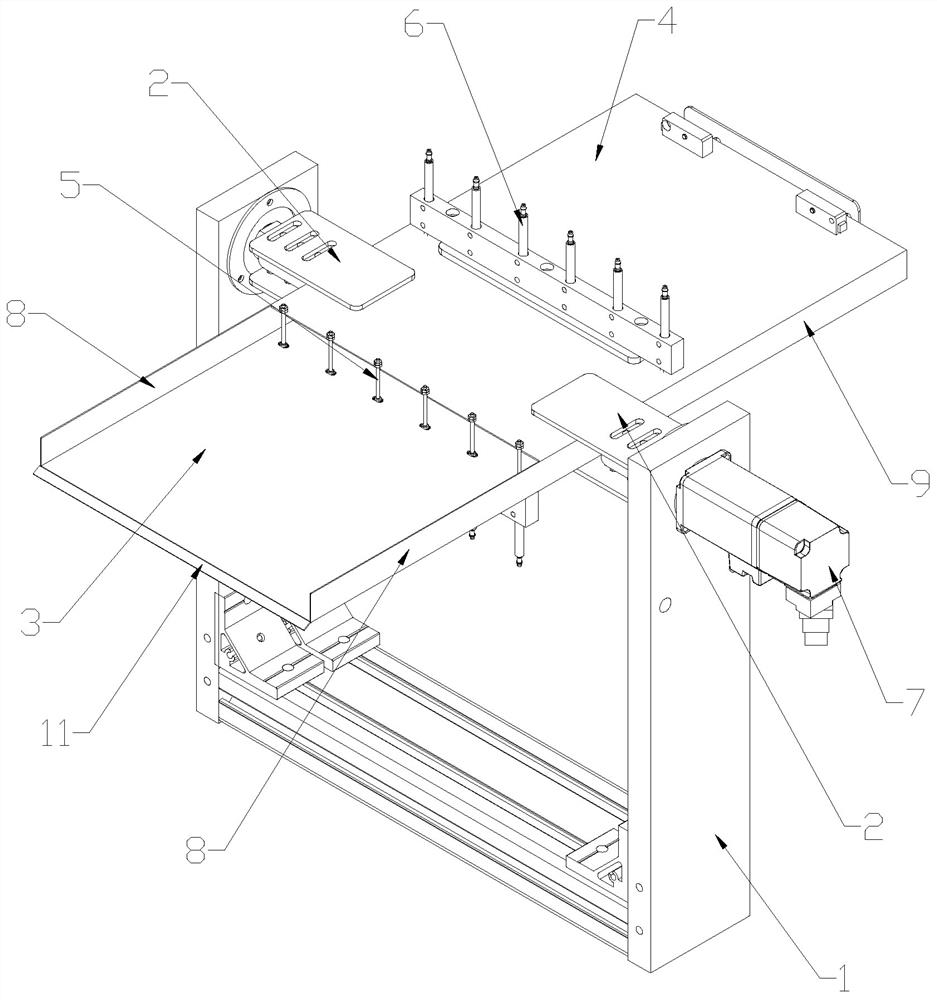

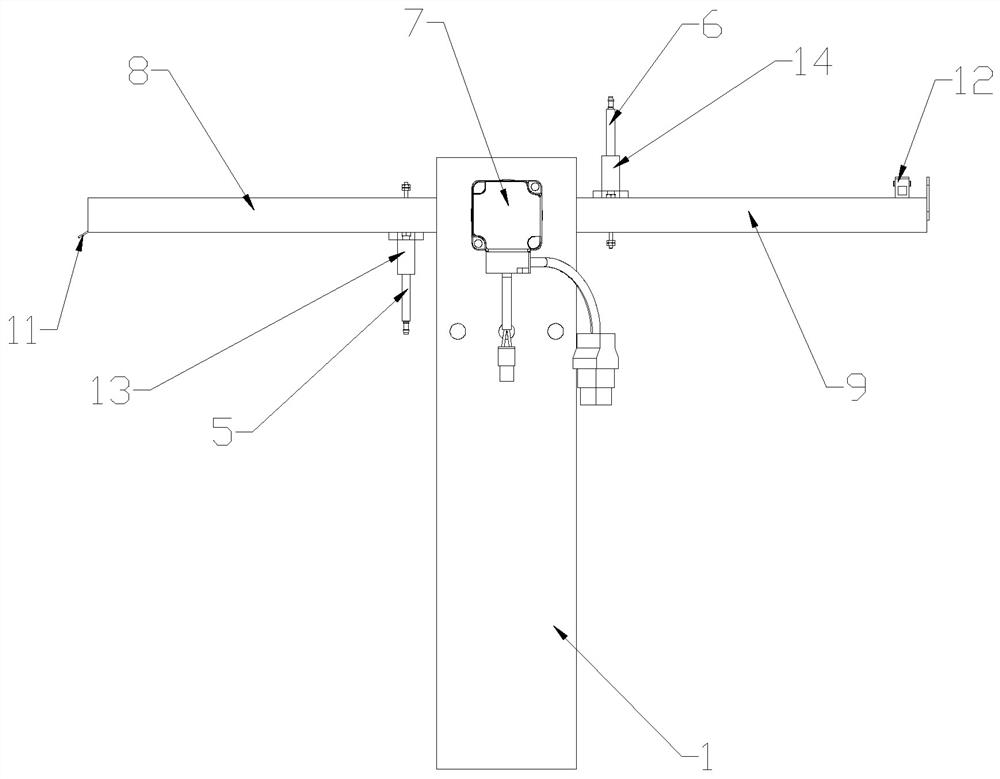

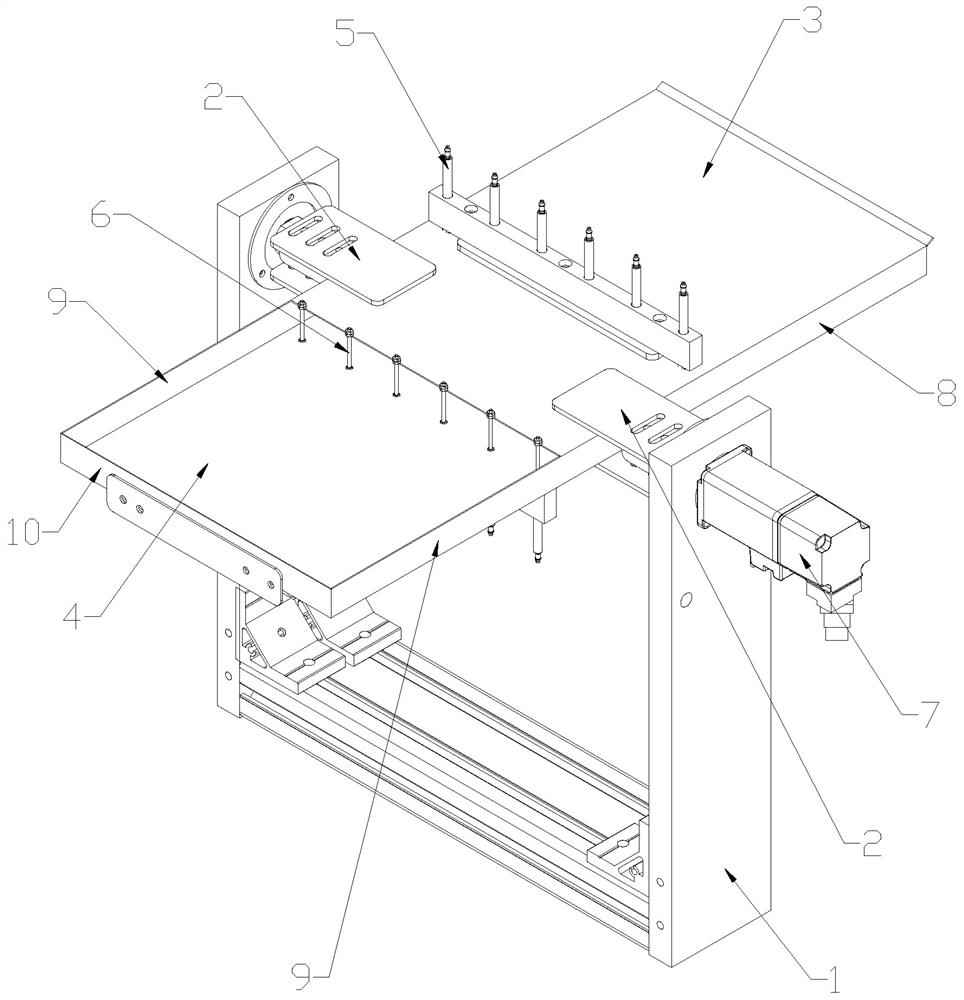

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] Such as Figure 1 to Figure 5 As shown, in this embodiment, a material in-situ turning platform includes a rotating frame 1, a movable splint 2, a first rotating table 3 and a second rotating table 4, and the opening of the first rotating table 3 faces upwards. , the opening of the second turntable 4 faces downward, one end of the first turntable 3 is connected to one end of the second turntable 4, the movable splint 2 is rotatably connected to the turntable 1, and the movable The splint 2 is clamped between the first rotary table 3 and the second rotary table 4 .

[0025] When the material is placed on the first rotary table 3 by the front-end structure, the rotary frame 1 acts as a fixed support, the middle part of the first rotary table 3 and the second rotary table 4 overlap, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com