Double-concave double-reflection type omnidirectional annular view filed imaging lens

An imaging lens and reflective technology, applied in the field of panoramic imaging lenses, can solve the problems of light energy loss, complex optical process, and difficult lens assembly, and achieve the effect of reducing difficulty and improving optical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

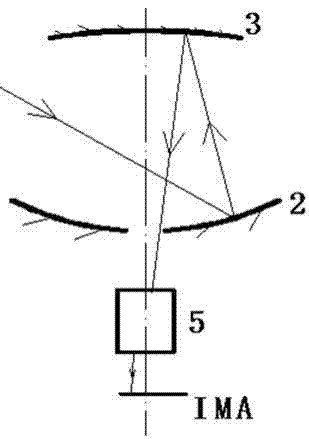

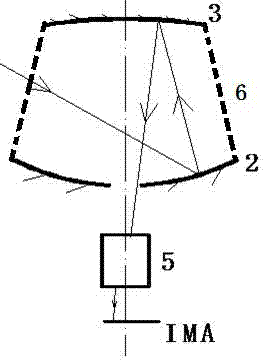

[0027] The reflective surfaces of the first concave reflective mirror surface 2 and the second concave reflective mirror surface 3 are opposite to each other, and they are both rotationally symmetrical about the optical axis (symmetry axis of the optical system); the relay lens group 5 is arranged on the first concave reflective mirror surface. Right behind the reflective mirror 2, that is, facing the middle hole of the first concave reflective mirror 2, and located between the first concave reflective mirror 2 and the focal plane (IMA); the first concave reflective mirror 2 and the second concave reflective mirror 3 are connected to each other through a suitable mechanical support mechanism 6 to form a mirror body.

[0028] The mechanical support mechanism 6 refers to a mechanism that can ensure that the optical interval and optical shading between the first concave reflective mirror surface 2 and the second concave reflective mirror surface 3 meet the specific optical design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com