Silicon on insulator (SOI)-based opto-isolator based on symmetrical vertical grating coupling structure

A vertical grating and vertical coupling technology, applied in the direction of coupling of optical waveguides, can solve the problems of inability to achieve monolithic integration, incompatible manufacturing processes, and restricting optical interconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

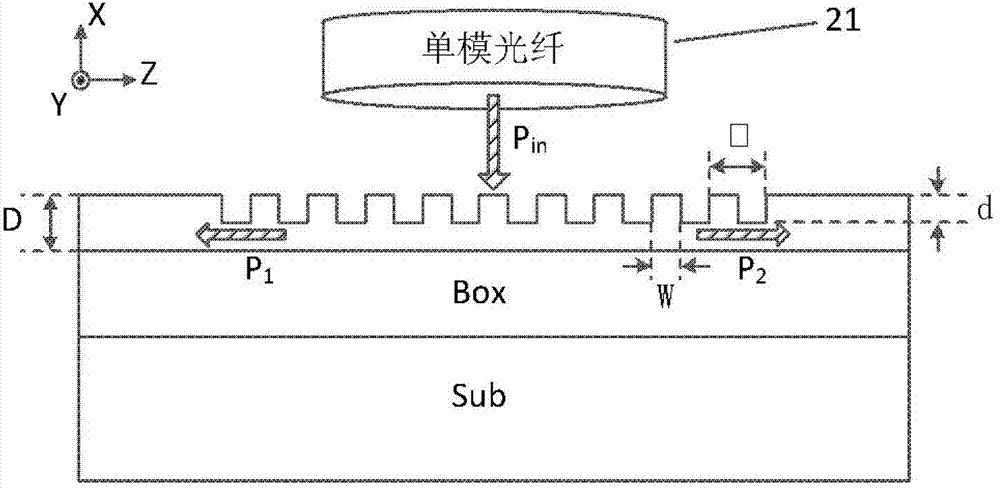

[0019] Because the present invention is a silicon-based optical isolator based on SOI substrate material design, for different buried oxide layer thicknesses and top-layer silicon thicknesses, the corresponding optimal design is also different in order to achieve functional requirements. Therefore, for convenience of description, the substrate of the present invention The bottom material defaults to specific implementation parameters, that is, the thickness of the buried oxide layer is 2 μm, and the thickness of the top silicon layer is 220 nm.

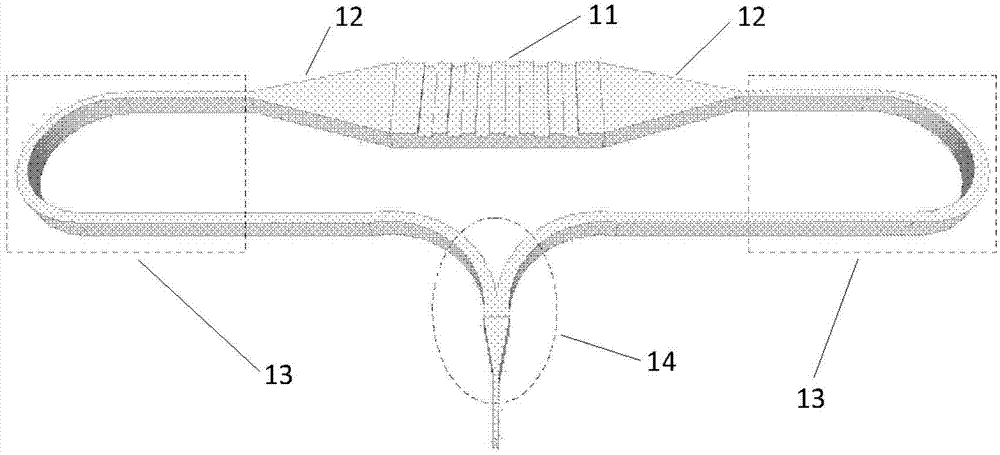

[0020] figure 1 For a three-dimensional schematic diagram of a specific embodiment of the present invention, refer to figure 1 As shown, the present invention provides a kind of SOI-based optical isolator based on symmetrical vertical grating coupling structure, comprising:

[0021] A vertical coupling grating 11, the vertical coupling grating 11 is a symmetrical vertical coupling grating 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com