Strip plate section form for machining T-section metal strips

A technology of cross-sectional shape and metal strip, applied in the direction of slender components, electrical components, building components, etc., can solve the problems of large local wear, elongation, uneven force on the mold, and improve the yield and service life. , the effect of eliminating cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are the embodiments made according to the technical solution of the present invention in conjunction with the accompanying drawings to further illustrate the present invention.

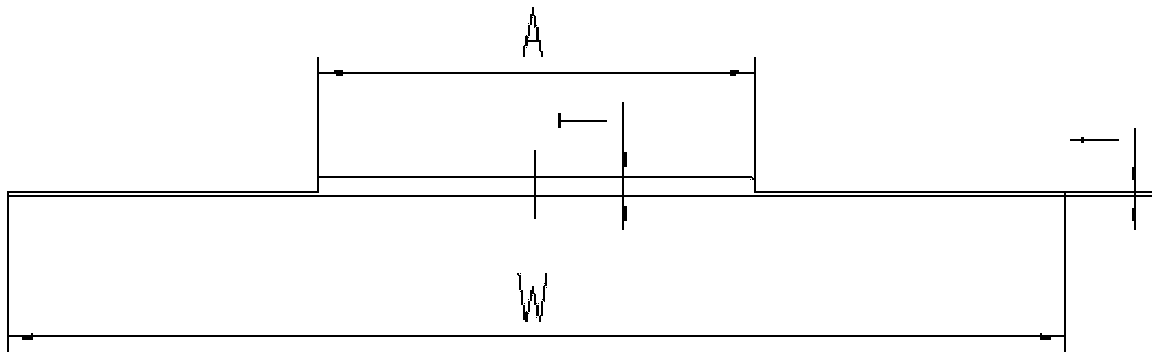

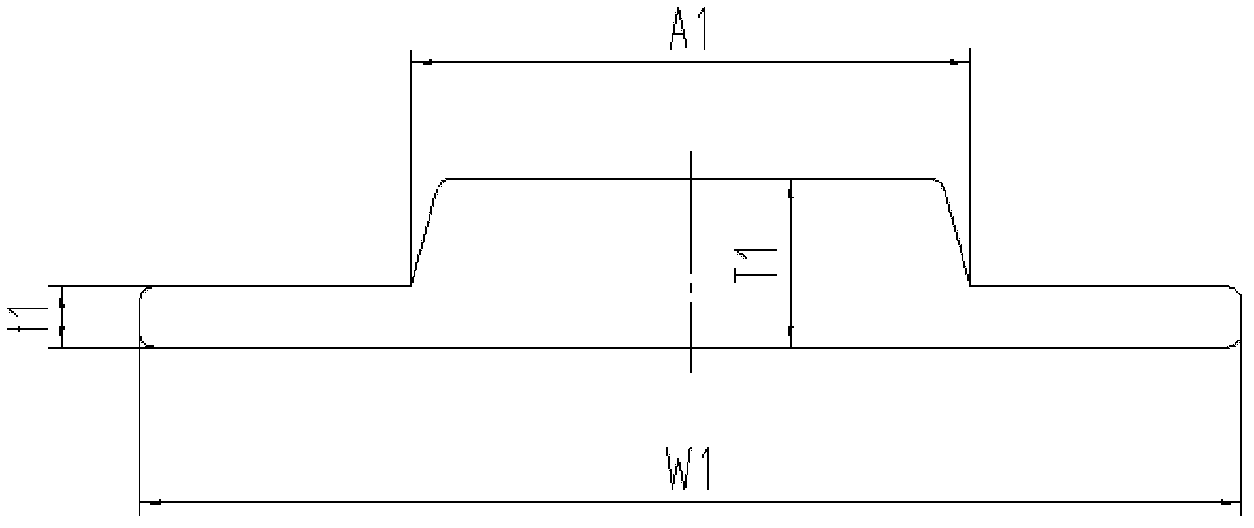

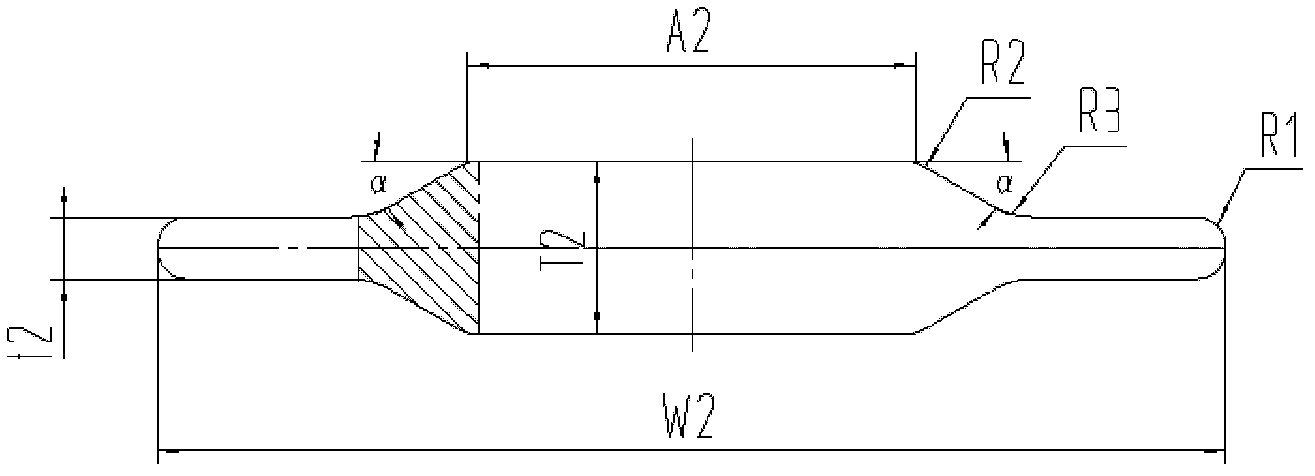

[0018] See figure 1 , the thin material thickness t=0.381mm of the finished product T-shaped strip, the thick material thickness T=1.27mm, A=27mm, W=64mm, the strip blank section shape of the present invention sees image 3 , Thickness t2=4.7mm for thin material, T2=14.5mm for thick material, A2=33mm, α=28°, W2=74mm, R1=1mm, R2=2mm, R3=4mm.

[0019] image 3 The cross-sectional shape of the strip blank shown is a T-shaped strip, and the cross-sectional shape of the strip blank can be a single strip blank cross-sectional shape ( image 3 ) for multiple combination molding ( Figure 4 ), forming a plurality of T-shaped strips is another form of the present invention, and is also within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com