High etching rate non-residue acidic aluminum etching solution and its preparation process

An etching rate and no residue technology, which is applied in the field of aluminum etching solution composition and its preparation process, can solve problems such as difficulty in controlling etching angle and etching amount, slow etching speed, affecting product yield and etching rate, etc., and achieves improved wettability. Effect of wet and etch uniformity, improved etch angle, reduced side etch amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

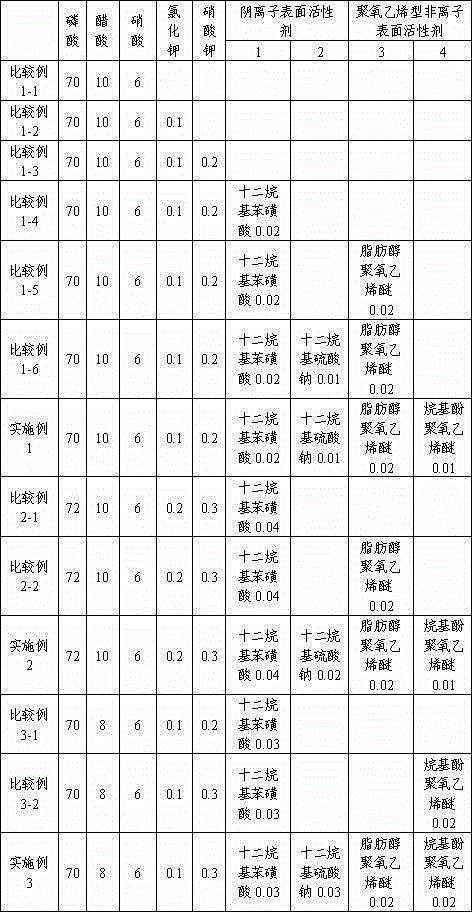

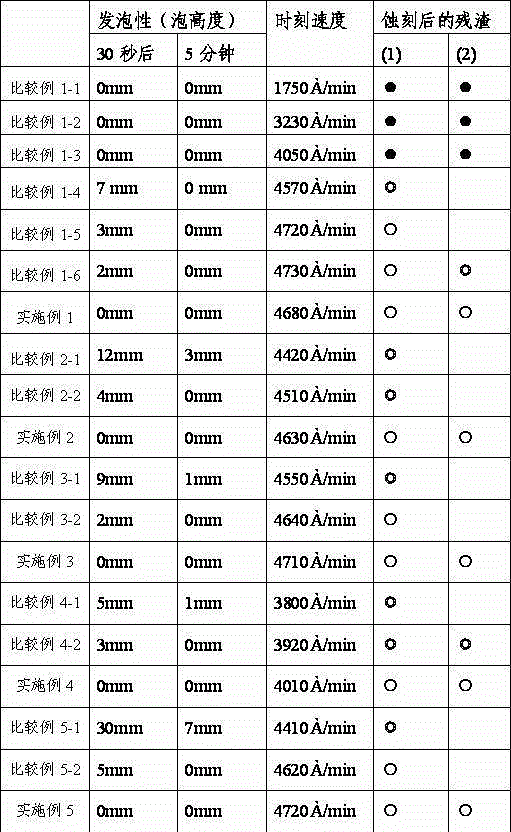

[0031] The invention is an acidic aluminum etching solution with high etching rate and no residue. The composition of the aluminum etching solution can be uniformly mixed with phosphoric acid, acetic acid, nitric acid, potassium chloride, metal nitrate, surfactant and pure water.

[0032] Wherein, the weight percentage of each raw material in the raw materials is prepared according to the components in the table respectively, and the rest is pure water; when the purity of raw materials changes, its proportioning should be adjusted.

[0033] Wherein, the purity of said phosphoric acid, acetic acid, and nitric acid can be respectively: 85.5% of phosphoric acid, 99.8% of acetic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com