Method for leaching out scandium from niobium tailing dressing

A tailings and leaching technology, which is applied in the field of metallurgy, can solve the problems of high cost, low scandium leaching rate, and difficult recovery of scandium, and achieve the effect of low cost, simple method, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

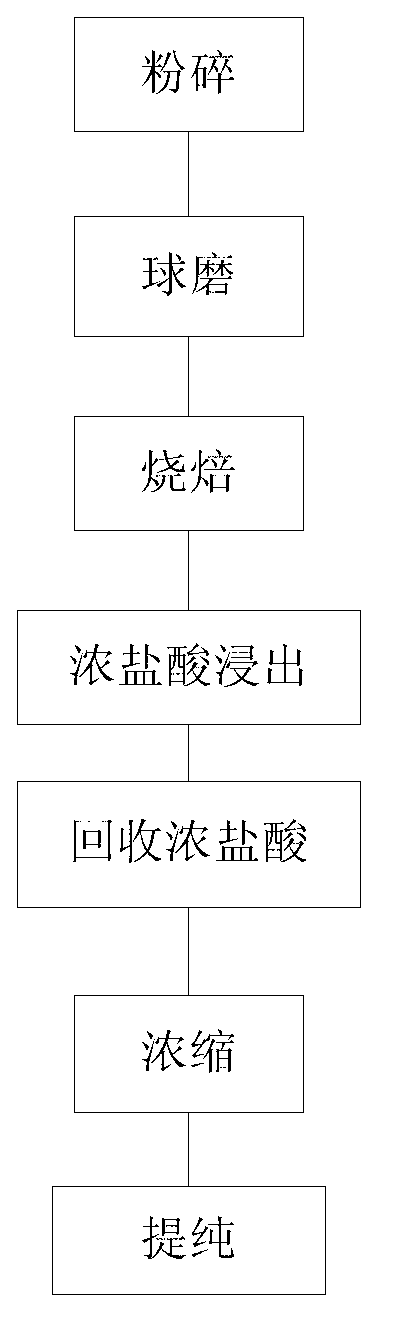

[0048] 1) The niobium-selected tailings are crushed to obtain niobium-selected tailings powder with a particle size of 100 mesh, and the niobium-selected tailings powder, CaCl 2 and reducing carbon powder according to the mass ratio of 20:15:4, fully ball milled and mixed evenly, adding tap water to obtain a slurry;

[0049] 2) Pellet the slurry, place it in an oven and dry it at 120°C for 2 hours, then place it in a box-type electric furnace and roast it at 800°C for 2 hours to obtain a roasted product;

[0050] 3) Grind the roasted product into fine powder, add concentrated hydrochloric acid with a mass percentage of 37% concentration at a solid-liquid mass-volume ratio (roasted product mass: leachate volume) of 1:3.2, and leach at 80°C for 2 hours to obtain leachate and leachate slag;

[0051] 4) Put the leaching solution in a graphite evaporator and heat it to 108°C to concentrate to obtain a concentrated solution. Stop heating when the volume of the concentrated solution...

Embodiment 2

[0053] 1) The niobium-selected tailings are crushed to obtain niobium-selected tailings powder with a particle size of 100 mesh, and the niobium-selected tailings powder, CaCl 2 and reducing carbon powder according to the mass ratio of 20:15:4, fully ball milled and mixed evenly, adding tap water to obtain a slurry;

[0054] 2) Pellet the slurry, place it in an oven and dry it at 120°C for 2 hours, then place it in a box-type electric furnace and roast it at 680°C for 6 hours to obtain a roasted product;

[0055] 3) Grind the roasted product into fine powder, add concentrated hydrochloric acid with a mass percent concentration of 37% at a solid-to-liquid mass-volume ratio of 1:2.1, and leaching at 60°C for 4 hours to obtain leaching liquid and leaching residue;

[0056] 4) Put the leaching solution in a graphite evaporator and heat it to 108°C to concentrate to obtain a concentrated solution. Stop heating when the volume of the concentrated solution is 50% to 60% of the volume...

Embodiment 3

[0058] 1) The niobium-selected tailings are crushed to obtain niobium-selected tailings powder with a particle size of 100 mesh, and the niobium-selected tailings powder, CaCl 2 and reducing carbon powder according to the mass ratio of 20:15:4, fully ball milled and mixed evenly, adding tap water to obtain a slurry;

[0059] 2) Pellet the slurry, place it in an oven and dry it at 120°C for 2 hours, then place it in a box-type electric furnace and roast it at 700°C for 3 hours to obtain a roasted product;

[0060] 3) Grind the roasted product into fine powder, add concentrated hydrochloric acid with a mass percent concentration of 37% at a solid-to-liquid mass-volume ratio of 1:2.8, and leaching at 90°C for 2 hours to obtain leaching liquid and leaching residue;

[0061] 4) Put the leaching solution in a graphite evaporator and heat it to 108°C to concentrate to obtain a concentrated solution. Stop heating when the volume of the concentrated solution is 50% to 60% of the volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com