Mixed bacterial agent for reducing viscosity of thick oil, as well as preparation method and use thereof

A mixed bacterial agent and viscosity-reducing technology is applied in the direction of microorganism-based methods, biochemical equipment and methods, and drilling compositions, etc. It can improve the emulsification viscosity reduction ability, high adaptability, and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A mixed bacterial agent for viscous reduction of heavy oil, composed of emulsifying crude oil bacteria Xanthomonas sp., medium- and long-chain hydrocarbon degrading bacteria Pseudomonss sp., colloidal asphaltenes Composed of Microbacterium sp. and Bacillus sp., in the mixed bacterial agent, the emulsified crude oil bacteria Xanthomonas spp., medium and long chain hydrocarbon degrading bacteria Pseudomonas spp., colloidal asphaltene degradation The volume ratio of the fermented liquid of the genus Microbacterium and the genus Bacillus is 20-100:40-180:30-100:10-80. The effective number of viable bacteria in the mixed bacterial agent is 10 8 ~10 10 pieces / ml.

Embodiment 2

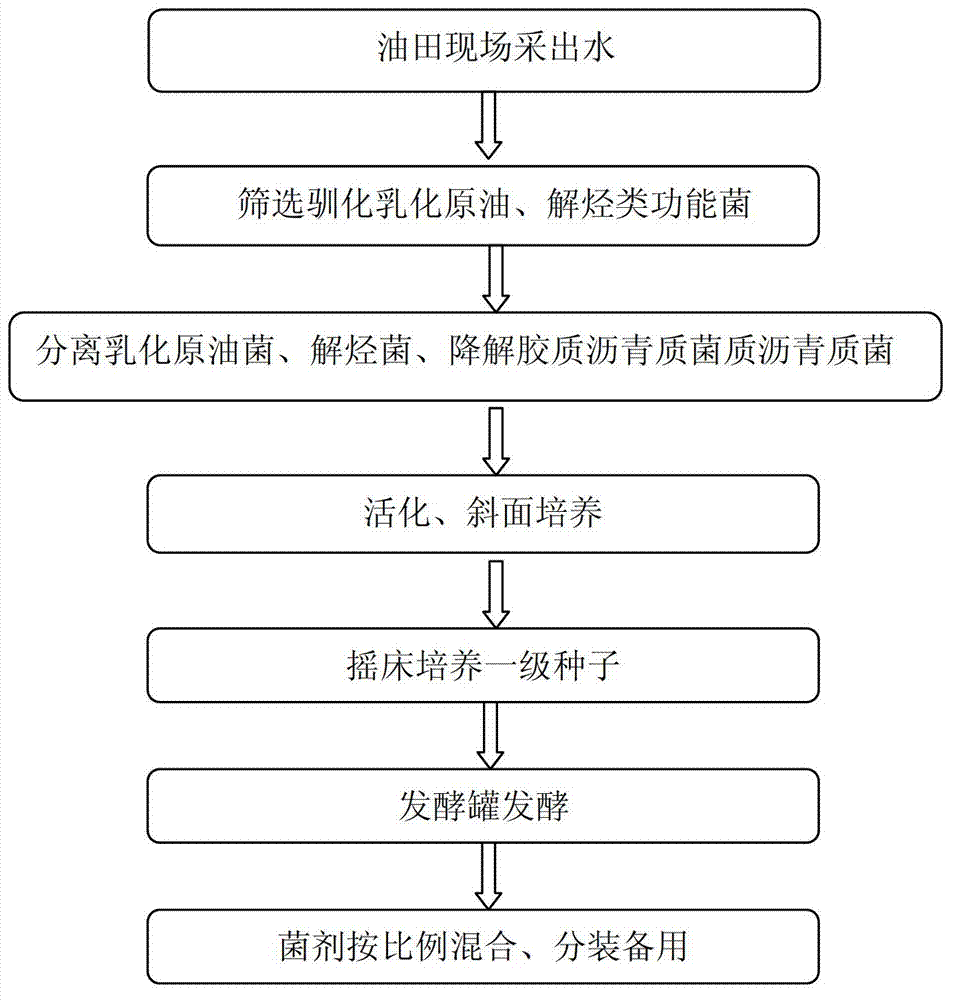

[0039] A method for preparing a mixed microbial agent for viscous reduction of heavy oil. The preparation process is to combine Xanthomonas sp., Pseudomonss sp., Microbacterium sp. ) and the primary seed liquid of Bacillus sp. were fermented and mixed separately. The specific steps are as follows:

[0040] (1) Source of bacteria

[0041] The strains were domesticated and screened from Bohai Bay produced water with viscous crude oil as the only carbon source, and they were Xanthomonas, Pseudomonas, Microbacterium and Bacillus;

[0042] (2) Preparation of primary seed solution

[0043] The strains obtained in step (1) were respectively activated on peptone yeast extract slant medium for 24h-30h, then transferred to liquid peptone yeast extract medium and activated in a shaker flask for 36-72h, as the primary seed solution. The activation temperature of the shake flask is 28-37°C, and the rotation speed is 100-250r / min.

[0044] Peptone yeast extract slant medium is beef extra...

Embodiment 3

[0049] A method for preparing a mixed bacterial agent for thick oil viscosity reduction, including the preparation of mixed bacterial fermentation broth, Xanthomonas sp., Pseudomonas sp., Microbacterium sp.) and Bacillus (Bacillus sp.), the bacterial fermentation liquid obtained through slant culture, shake flask activation culture and fermentation culture respectively, the specific operation steps are as follows:

[0050] (1) Incline medium

[0051] Prepare beef extract protein aged solid medium, the specific steps are: yeast extract 5g, protein aged 10g, NaCl 10g, distilled water 1000m1, pH 7.2-7.4, agar 1.5%-2%, stir evenly, and sterilize at 121.0°C for 25min. After sterilization, make inclined planes and place them on ultra-clean workbenches. Aseptically inoculate the preserved strains onto the inclined test tube, culture the strains at 30-37°C for 24-36 hours, and wait for the bacterial lawn to cover the inclined surface for later use.

[0052] (2) Preparation of seed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com