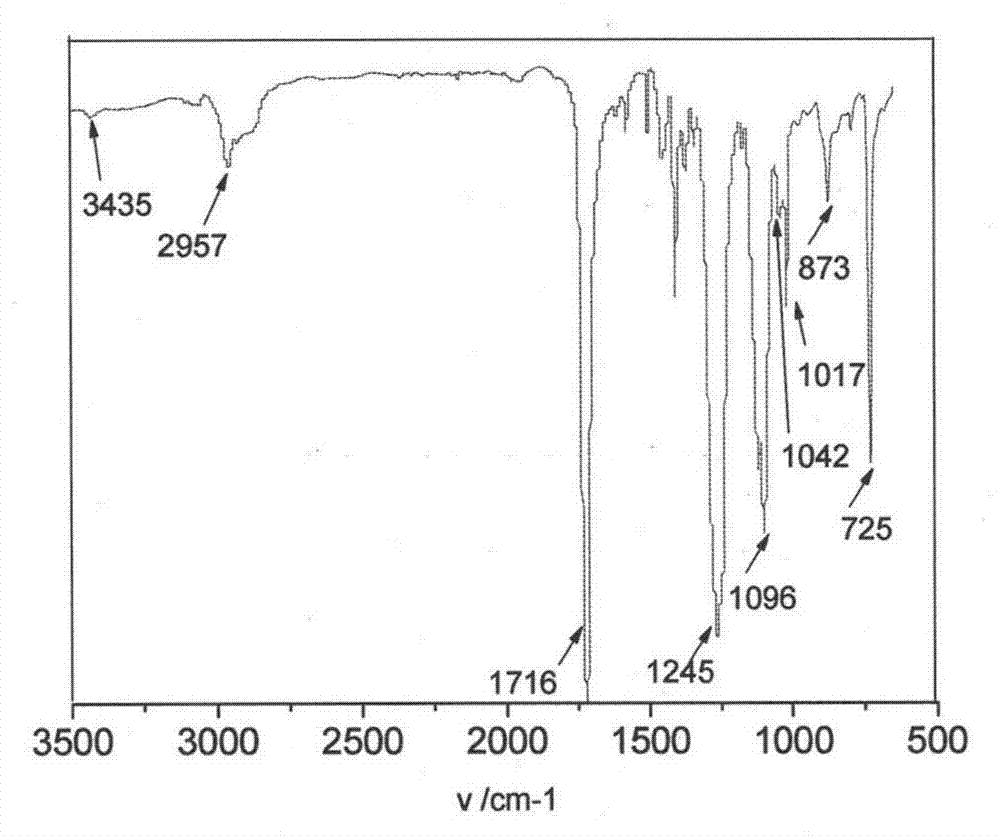

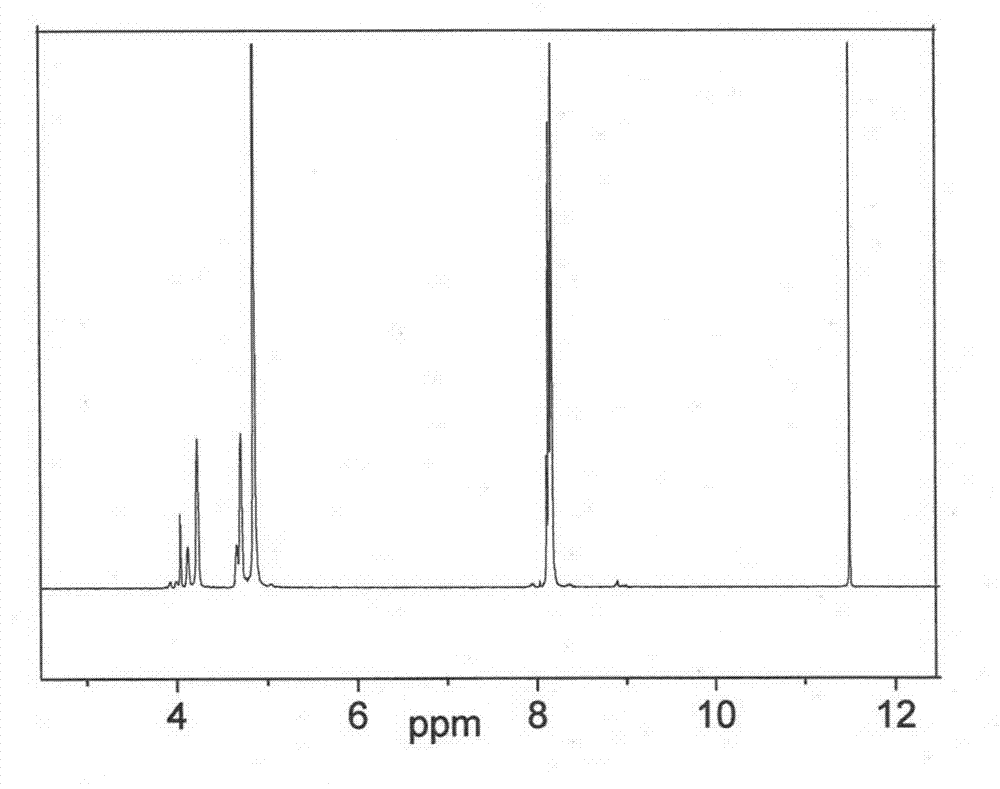

Hydrophilic polyester and preparation method thereof

A hydrophilic, polyester technology, applied in the direction of one-component copolyester rayon, etc., to achieve the effect of improving hydrophilic performance, improving hydrophilic performance and reducing development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

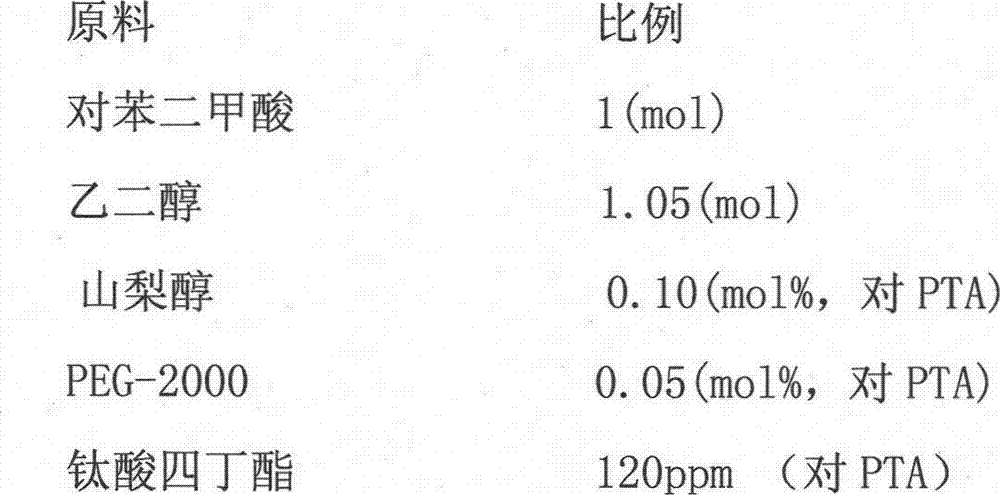

Embodiment 1

[0040]

[0041] Mix terephthalic acid and ethylene glycol in proportion to prepare slurry. Mix the prepared slurry with the catalyst tetrabutyl titanate in proportion and then add it to the esterification reactor for the first esterification reaction. The temperature of the first esterification reaction is 225°C, the reaction time is 4 hours, and the relative pressure of the reaction is 0 MPa. The by-product water is separated and collected by a fractionating tower, and the collection amount is measured with a graduated cylinder, and the theoretical value is calculated according to the reaction formula. When the collection amount of water reaches 82% of the theoretical value, add sorbitol and polyethylene glycol (PEG-2000 ) to carry out the second esterification reaction, the temperature of the second esterification reaction is 240° C., the pressure is normal pressure, and the esterification reaction time is 1 h. After the esterification reaction is completed, the esterifi...

Embodiment 2

[0045]

[0046]

[0047] Mix terephthalic acid and ethylene glycol in proportion to prepare slurry. Mix the prepared slurry with ethylene glycol antimony, antioxidant 1010 and trimethyl phosphate in proportion and then add it to the esterification reactor for the first esterification reaction. The temperature of the first esterification reaction is 250°C, and the reaction time is 0.5h, the relative pressure of the reaction is 0.4MPa. Water is separated and collected by a fractionating tower, and the collected amount is measured with a measuring cylinder, and the theoretical value is calculated according to the reaction formula. When the collected amount of by-product water reaches 95% of the theoretical value, add sorbitol and polyethylene glycol (PEG-4000 ) to carry out the second esterification reaction, the temperature of the second esterification reaction is 260°C, the pressure is normal pressure, and the esterification reaction time is 0.5h. After the esterificatio...

Embodiment 3

[0049]

[0050] Mix terephthalic acid and ethylene glycol in proportion to prepare slurry. Mix the prepared slurry with the mixture of antimony trioxide and tetrabutyl titanate, antioxidant 168 and alkyl phosphoric acid diester in proportion, and then add it to the esterification reactor for the first esterification reaction. The temperature of the first esterification reaction is The temperature is 240°C, the reaction time is 3h, and the relative pressure of the reaction is 0.3MPa. Water is separated and collected by a fractionating tower, and the collected amount is measured with a graduated cylinder, and the theoretical value is calculated according to the reaction formula. When the collected amount of by-product water reaches 92% of the theoretical value, add sorbitol and polyethylene glycol (PEG-6000 ) to carry out the second esterification reaction, the temperature of the second esterification reaction is 250° C., the pressure is normal pressure, and the esterificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com