Method for comprehensively treating sewage of chemical fiber oiling agents in production plants

A chemical fiber oil, comprehensive treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc. Large and other problems, to reduce the inhibition of high COD concentration, less dead space, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

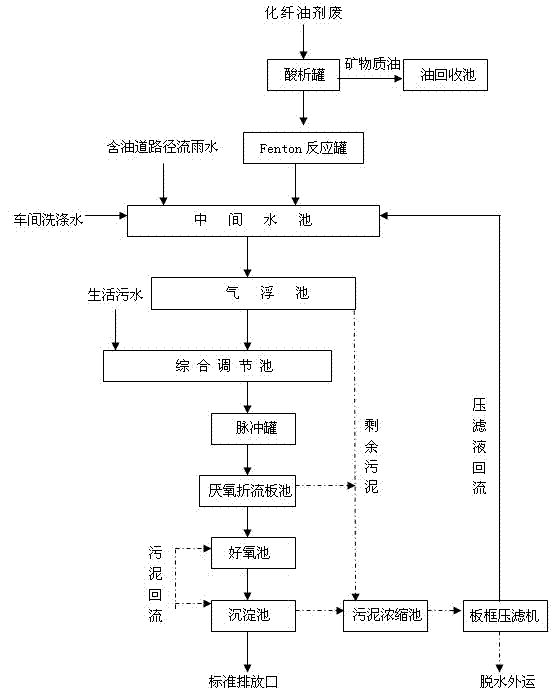

[0019] Attached below figure 1 And examples further illustrate the present invention.

[0020] Taking the sewage treatment process in the production plant of a chemical fiber oil production enterprise as an example, during the sewage treatment process in the production plant of the chemical fiber oil production enterprise, the amount of chemical fiber oil agent wastewater produced is about 2 tons per day, and the highest concentration of COD can reach 1×10 6 mg / L. In addition, the toilets and restaurants in the factory will produce about 7 tons of domestic sewage per day, with a maximum concentration of COD of 500 mg / L; the production of washing water in the workshop is about 2 tons per day, with a maximum concentration of COD of 1700 mg / L ; The amount of effluent in the oily road path generated by rain in the finished product loading and unloading area and the truck parking lot is about 9 tons per day.

[0021] process such as figure 1 , chemical fiber oil waste water firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com