Method for synthesizing silver indium sulfide heterojunction structure nano material through hydro-thermal mode

A technology of silver indium sulfide and heterostructure, which is applied in the field of hydrothermal synthesis of silver indium sulfide heterostructure nanomaterials, can solve the problems of complex reaction conditions, excessively high reaction temperature, long reaction time and the like, and achieves simple raw materials and product purity. High effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

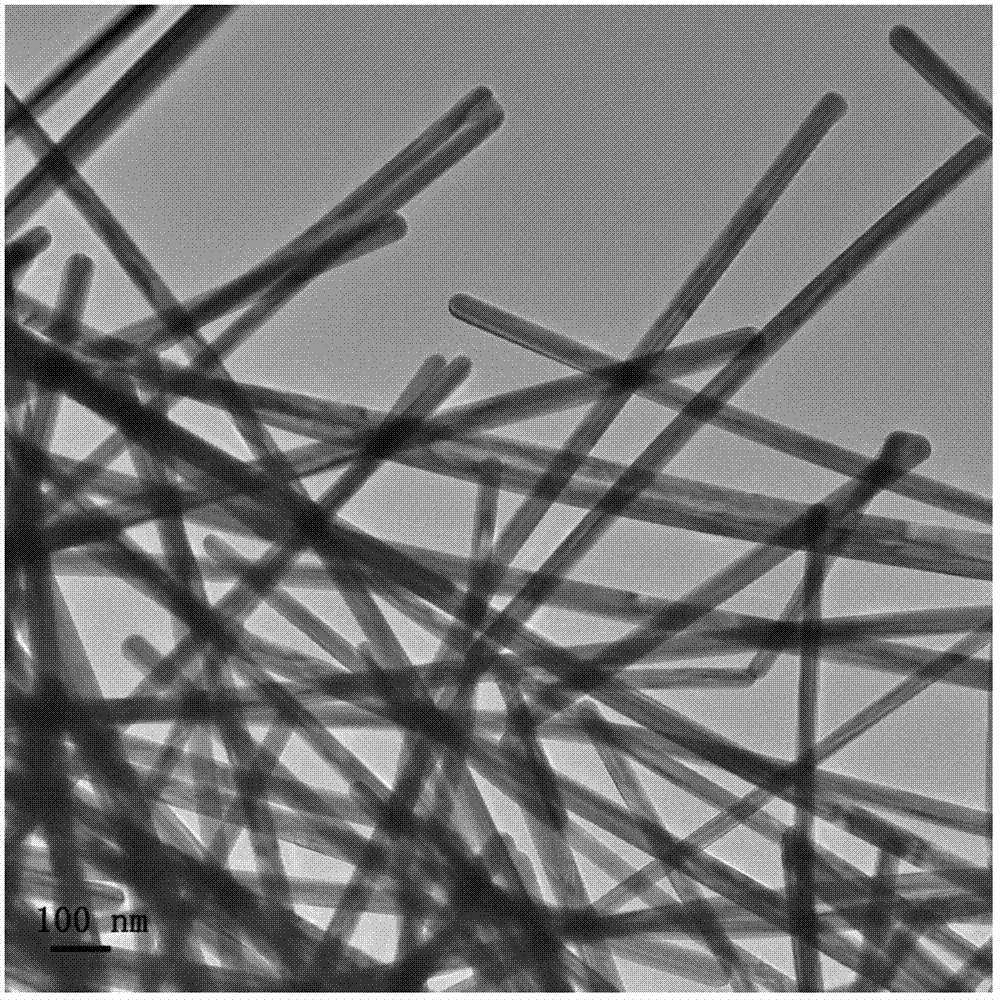

Embodiment 1

[0032] Follow the preparation process. First drop 2mL of the alcohol suspension of silver nanowires into 23ml of deionized water, and stir magnetically for 5 minutes, then add 0.231g of indium trichloride tetrahydrate solid into the previous mixed solution, and stir magnetically for 7 minutes to obtain a new mixed solution ; Another 260mg of cetyltrimethylammonium bromide was added, and the stirring was continued for 10 minutes; finally, 178mg of thioacetamide was added, and magnetically stirred for 10 minutes to obtain the precursor of the reaction. The mixed solution was poured into a 100ml three-necked round bottom flask, and placed in a reaction heating reaction system with a reflux device to keep the temperature while refluxing. The reaction conditions were: 95°C, 80min. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a p...

Embodiment 2

[0034]Follow the preparation process. Add 0.231g of indium trichloride tetrahydrate into a beaker containing 25ml of deionized water, and stir magnetically for 7 minutes to obtain a transparent and clear solution; add 260mg of hexadecyltrimethylammonium bromide and continue to stir for 10 minutes; When the solution was still clear, 178 mg of thioacetamide was finally added and magnetically stirred for 10 minutes to obtain a pale yellow solution, which was used as a reaction precursor. The solution was injected into a 100ml three-necked round-bottomed flask, and placed in a reaction heating reaction system with a reflux device to keep the temperature constant while refluxing. The reaction conditions were: 95°C, 80min. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a powder. The scanning electron microscope test sample is to t...

Embodiment 3

[0036] Follow the preparation process. Follow the preparation process. First drop 2mL of the alcohol suspension of silver nanowires into 23ml of deionized water, and stir magnetically for 10 minutes, then add 0.231g of indium trichloride tetrahydrate solid into the previous mixed solution, and stir magnetically for 7 minutes to obtain a new mixed solution ; Finally, 178mg of thioacetamide was added and magnetically stirred for 10 minutes to obtain the precursor of the reaction. Pour the mixed solution into a 100ml three-necked round bottom flask, and keep the temperature constant while refluxing in a reaction heating reaction system with a reflux device. The reaction conditions are: 95°C, 80min. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a powder. The scanning electron microscope test sample is to take out a small amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com