Retrofit technology for cutting and lengthening ships via dry-type trolley method

A trolley and ship technology, which is applied in the field of dry-type trolley method for ship cutting and lengthening, can solve the problems of complex process operation, lengthened refit cycle, and narrow range of ship types, so as to achieve simple and reliable process operation, reduce the number of docking and undocking, and apply The effect of a wide range of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

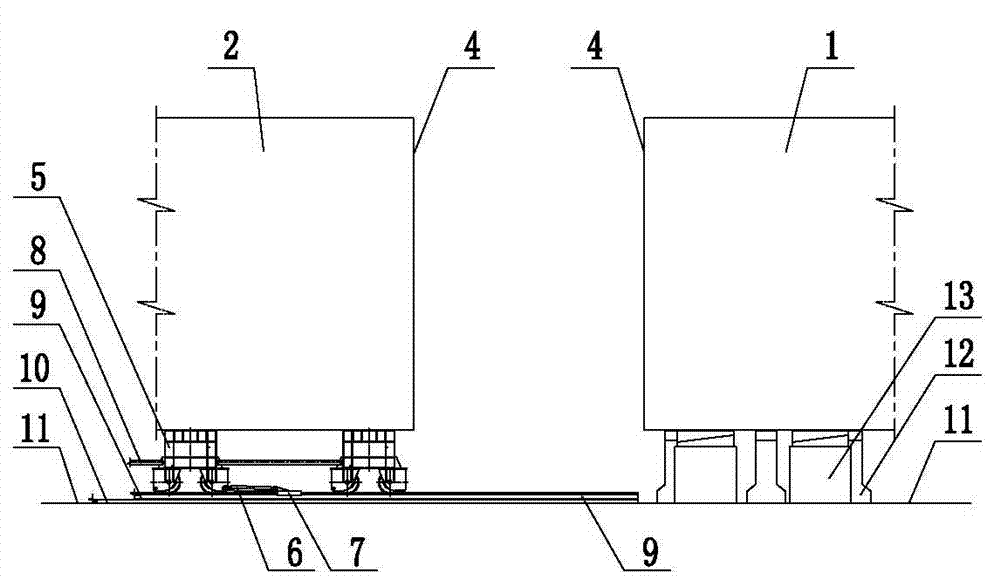

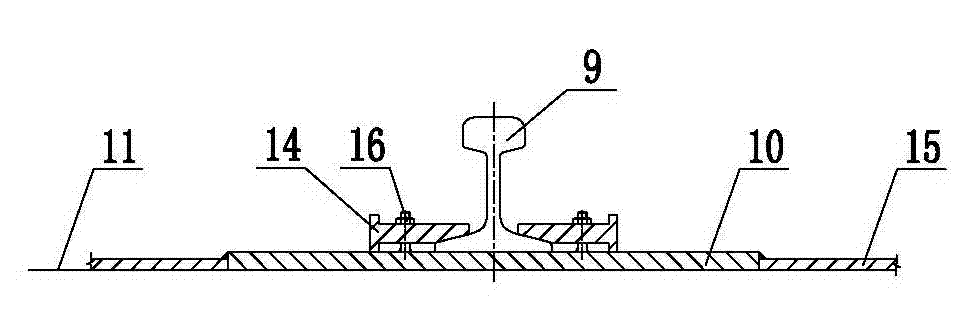

[0039] This embodiment is illustrated by the refitting of the ship "Nuohang Kobe" of the Norwegian Hoag Company. The entire ship cutting and lengthening refitting technology includes new section prefabrication, hull marking, hull structure strengthening, ship docking precision control, and docking pier. Arrangement, laying of combined guide rails, connection and placement of combined trolleys, precise docking of ships, installation and arrangement of thrust devices, support for the front end of the bow section and rear end of the stern section, segmental cutting, shifting of the bow section, and adding new sections Assembled and closed with the stern section, the bow section and the newly added section are precisely aligned, positioned and closed.

[0040] The main steps are described in detail as follows:

[0041] 1. Newly added seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com