Nano intermetallic compound soldering paste and preparation method thereof

A technology of intermetallic compounds and nano-metals, applied in the field of materials, can solve the problems of incompatibility between manufacturability and high temperature reliability, high energy consumption of spray pyrolysis, and decreased reliability of connection interfaces, etc., achieving huge development potential and application Foreground, time-saving interconnection process, good shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

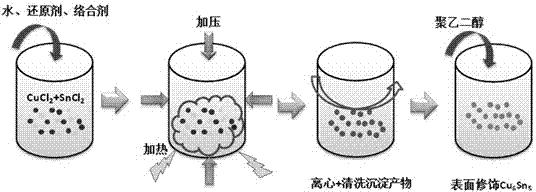

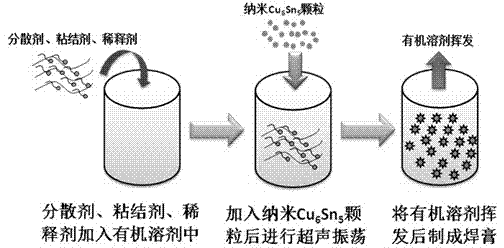

[0021] Specific implementation mode one: as figure 1 and 2 As shown, this embodiment combines the preparation of Cu 6 sn 5 The concrete method of nano solder paste is described in detail to the present invention:

[0022] Step 1: will contain CuCl 2 and SnCl 2 The metal salt of the metal salt is used as a precursor, placed in the polytetrafluoroethylene lining of the autoclave according to the ratio of 2:1~1.2:1;

[0023] Step 2: Add water to the autoclave to 60-80% of its volume;

[0024] Step 3: Add an appropriate amount of reducing agent and complexing agent, immediately seal the autoclave, pressurize to 1.2MPa, and heat to 80~110°C, wherein the reducing agent can be KBH 4 , N 2 h 4 Or Zn, complexing agent can be propylene diamine;

[0025] Step 4: After reacting for 5-20 hours, cool the autoclave to room temperature naturally, and take out the precipitated product for later use;

[0026] Step 5: Place the above precipitated product in a centrifuge for centrifugat...

specific Embodiment approach 2

[0031] Specific embodiment two: This embodiment combines the preparation of Ni 3 sn 4 The concrete method of nano solder paste is described in detail to the present invention:

[0032] Step 1: will contain NiCl 2 and SnCl 2 As a precursor, the metal salt is placed in the polytetrafluoroethylene lining of the autoclave according to the ratio of 3:4;

[0033] Step 2: Add water to the autoclave to 60-80% of its volume;

[0034] Step 3: Add an appropriate amount of reducing agent and complexing agent, immediately seal the autoclave, pressurize to 1.2MPa, and heat to 80~110°C, wherein the reducing agent can be KBH 4 , the complexing agent can be propylene diamine;

[0035] Step 4: After reacting for 5-20 hours, cool the autoclave to room temperature naturally, and take out the precipitated product for later use;

[0036] Step 5: Place the above precipitated product in a centrifuge for centrifugation, wash with deionized water, and then wash with ethanol three times;

[0037]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com