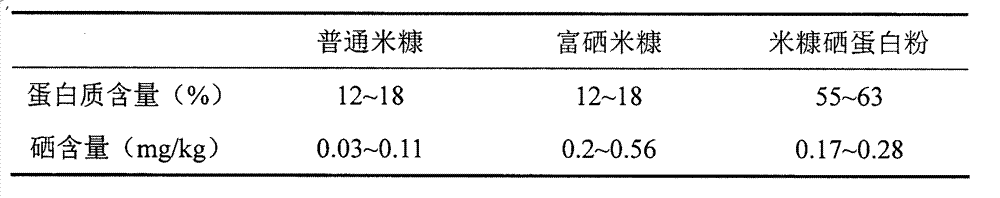

Preparation method of rice bran selenoprotein powder

A protein powder and rice bran technology, which is applied in the field of functional food processing and selenium-enriched rice by-product processing, can solve the problems of high process cost and achieve high acceptability, avoid waste, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Raw material pretreatment: The same batch of selenium-enriched rice is dehulled with a rice huller and milled with a rice mill to obtain coarse rice bran, which is then ground with a pulverizer and passed through an 80-mesh sieve.

[0026] (2) Degreasing: use n-hexane, the ratio of solid to liquid is 1:5, degrease twice on a magnetic stirrer, 3 hours each time, centrifuge, and air-dry the precipitate overnight in a fume hood.

[0027] (3) Removing polyphenols: Mix 65% ethanol with defatted rice bran powder (the ratio of solid to liquid is 1:4), stir on a magnetic stirrer for 20 minutes, and then centrifuge. This process is repeated 3 times. The precipitates after centrifugation were combined and air-dried overnight in a fume hood.

[0028] (4) Alkali extraction: the defatted rice bran powder was extracted twice with NaOH at a concentration of 0.08 mol / L, the ratio of solid to liquid was 1:10, the temperature was 40°C, and the time was 3 h, centrifuged, and the super...

Embodiment 2

[0033] (1) Raw material pretreatment: The same batch of selenium-enriched rice is dehulled with a rice huller and milled with a rice mill to obtain coarse rice bran, which is then ground with a pulverizer and passed through an 80-mesh sieve.

[0034] (2) Degreasing: use n-hexane, the ratio of solid to liquid is 1:5, degrease twice on a magnetic stirrer, 3 hours each time, centrifuge, and air-dry the precipitate overnight in a fume hood.

[0035] (3) Removing polyphenols: Mix 65% ethanol with defatted rice bran powder (the ratio of solid to liquid is 1:4), stir on a magnetic stirrer for 20 minutes, and then centrifuge. This process is repeated 3 times. The precipitates after centrifugation were combined and air-dried overnight in a fume hood.

[0036] (4) Alkaline extraction: the defatted rice bran powder was extracted twice with NaOH at a concentration of 0.08mol / L, the ratio of solid to liquid was 1:15, the temperature was 35°C, and the time was 2h, centrifuged, and the super...

Embodiment 3

[0041] (1) Raw material pretreatment: The same batch of selenium-enriched rice is dehulled with a rice huller and milled with a rice mill to obtain coarse rice bran, which is then ground with a pulverizer and passed through an 80-mesh sieve.

[0042] (2) Degreasing: use n-hexane, the ratio of solid to liquid is 1:5, degrease twice on a magnetic stirrer, 3 hours each time, centrifuge, and air-dry the precipitate overnight in a fume hood.

[0043] (3) Removing polyphenols: Mix 65% ethanol with defatted rice bran powder (the ratio of solid to liquid is 1:4), stir on a magnetic stirrer for 20 minutes, and then centrifuge. This process is repeated 3 times. The precipitates after centrifugation were combined and air-dried overnight in a fume hood.

[0044] (4) Alkali extraction: the defatted rice bran powder was extracted twice with NaOH at a concentration of 0.02 mol / L, the ratio of solid to liquid was 1:20, the temperature was 40°C, and the time was 2 h, centrifuged, and the super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com