Illumination member sealed with silicone rubber and manufacturing method for same

A technology of silicone rubber and silicone rubber composition, which can solve the problems of design cost restriction and other problems while being effective in vibration, and achieve the effects of preventing internal loss, excellent weather resistance and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

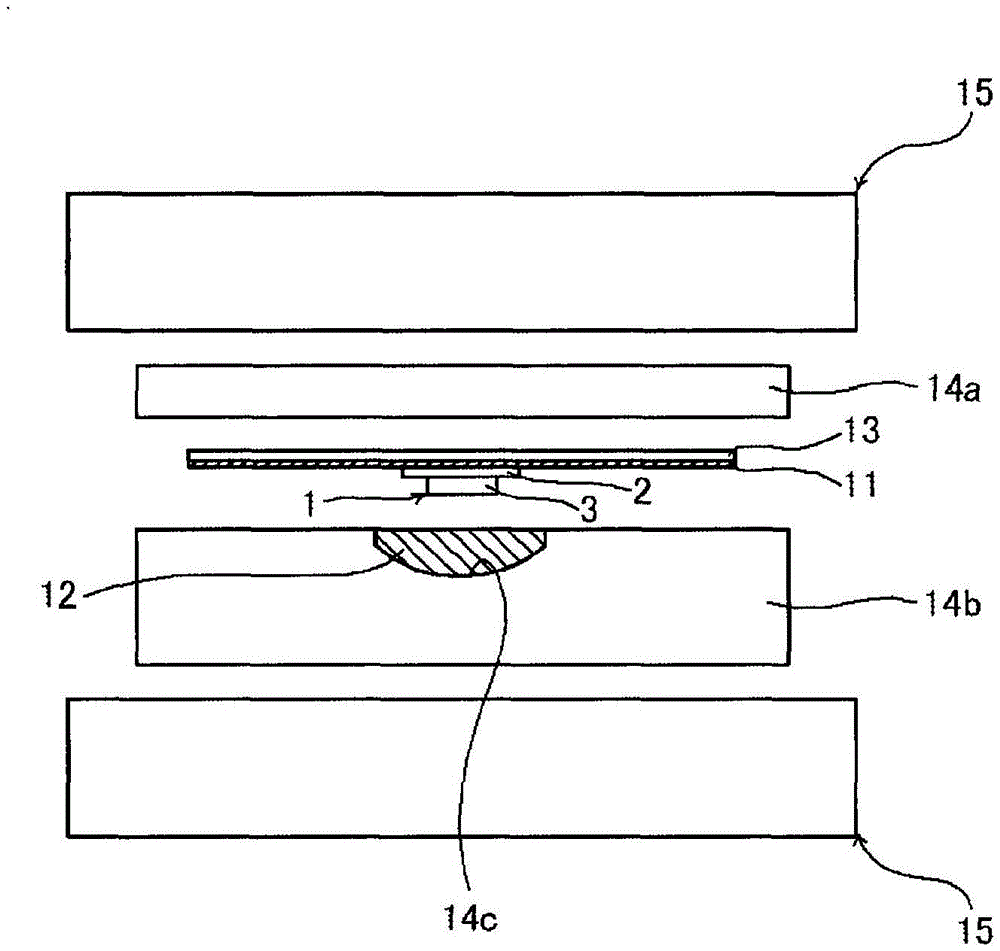

Image

Examples

Embodiment 1

[0101] As silicone rubber composition I capable of forming silicone rubber A having transparency, 100 parts by mass of (a-1) above, 15 parts by mass of (c-1), and (f -1) 4.5 parts by mass and 1 part by mass of ion-exchanged water were mixed and kneaded using a kneader while heating at 170° C. for 2 hours to make them uniform, and an unvulcanized silicone rubber compound A was prepared.

[0102] 100 parts by mass of unvulcanized silicone rubber compound A, 0.2 parts by mass of vinyl siloxane complex of chloroplatinic acid (b-1), and 0.7 parts by mass of curing agent (b-2) were prepared as (b-1 ) of 0.2 parts by mass of ethynylcyclohexanol as a control agent was kneaded using twin rolls to obtain a silicone composition A.

[0103]As the silicone rubber composition II capable of forming silicone rubber B, 350 parts by mass of alumina powder (manufactured by Showa Denko Co., Ltd., Almina AL-24) was added to the above-mentioned silicone composition A (the above-mentioned compoundin...

Embodiment 2

[0108] As silicone rubber composition I for forming silicone rubber A, 3 parts by mass of titanium oxide (color tone adjusting agent) with an average particle diameter of 3 μm was added to 100 parts by mass of silicone composition A of Example 1 to form a silicone composition b.

[0109] As the silicone rubber composition II for silicone rubber B, the BET specific surface area was set to 69 m 2 10 parts by mass of acetylene black powder per g was kneaded and blended in the same manner with twin rolls to obtain silicone composition B-2.

[0110] Except for this, a sheet and a molded product were obtained in the same manner as in Example 1. The obtained product was evaluated as follows. In addition, the electrical resistivity was evaluated as an electrostatic property of the rubber alone on the side opposite to the light-emitting surface.

Embodiment 3

[0112] As silicone rubber composition I for silicone rubber A, 100 parts by mass of the above-mentioned (a-2), 10 parts by mass of (c-1), and 4.5 parts by mass of (f-1) as a surface treatment agent of (c-1) 1 part by mass of ion-exchanged water and 1 part by mass of ion-exchanged water were mixed and kneaded while heating at 170° C. for 2 hours using a kneader to make it homogeneous, and unvulcanized silicone rubber compound B was prepared.

[0113] A silicone composition C was obtained in the same manner as in Example 1, except that the unvulcanized silicone compound B was used instead of the unvulcanized silicone compound A.

[0114] As silicone rubber composition II for silicone rubber B, 330 parts by mass of alumina powder (manufactured by Showa Denko Co., Ltd., Almina AL-24) with a BET specific surface area of 69m 2 10 parts by mass of acetylene black powder per g was kneaded and blended in the same manner using twin rolls to obtain silicone composition C-2.

[0115] Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com