Device and method for measuring film thermoelectric performance parameters

A technology of thermoelectric properties and temperature measuring devices, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as low measurement accuracy and insufficient film materials, and achieve small size and insensitive contact resistance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

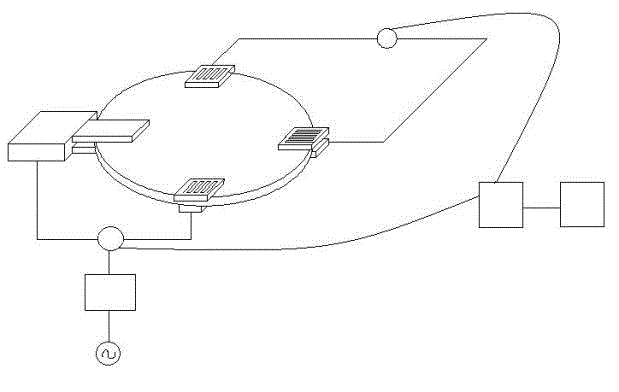

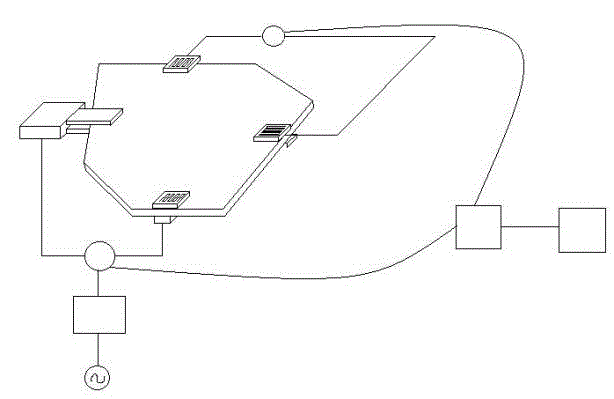

[0032] see Figure 1~Figure 3 , the measurement includes: temperature measuring device (2, 3, 4), data acquisition device (8), heat sink (1), current source (7), stage (5), computer (9), temperature control box (10) and a voltmeter (6), characterized in that: the sample to be tested is fixed on the stage (5); the first contact point (1′) of the sample to be tested is connected to the heat sink (1), and The second, third, and fourth contact points (2′), (3′), and (4′) are respectively connected to a temperature measuring device, and the power supply (11) is connected to the current source ( 7), the current source (7) is connected to the heat sink (1), the temperature measuring device a (2), the temperature measuring device b (3) and the temperature measuring device c (4) are connected to the voltmeter (6), the current source (7 ) and the voltmeter (6) are connected to the data acquisition device (8), and the output of the data acquisition device (8) is connected to the compute...

Embodiment 2

[0034] This embodiment is basically the same as the first embodiment, and the special feature is that: the film to be tested can be a uniform film or a non-uniform film, and can be of any shape. The temperature measuring devices (2, 3, 4) are Pt100, Pt10, Pt1000, Cu50 or Cu100 temperature measuring resistances, or thermocouples. The contact points are a series of contact points, and the number of the contact points is 4-20. The operation steps of the measurement are as follows:

[0035] 1) The sample needs to be cut into a shape similar to the stage (5);

[0036] 2) The first contact point (1') of the film sample to be tested is connected to the heat sink (1), and the second, third and fourth contact points (2', 3', 4') are respectively connected to a measuring Temperature resistance (2, 3, 4);

[0037] 3) Input current to the first and second contact points (1', 2'), measure the voltage between the third and fourth contact points (3', 4'), and then 1. Input current at the...

Embodiment 3

[0043] The method for measuring the thermoelectric performance parameters of the thin film uses the above-mentioned device for measuring the thermoelectric performance parameters of the thin film. The specific implementation steps of the method are:

[0044] 1) Prepare several film samples of different thicknesses to be tested, and cut out a square similar to the stage (5);

[0045] 2) One side of the film sample to be tested is connected to a heat sink, and the other three sides are respectively connected to a heating resistor and a thermocouple;

[0046] 3) Input the current to the first contact point (1') and the second contact point (2'), measure the voltage between the third contact point (3') and the fourth contact point (4'), and then 1. Input the current at the third contact point (1' and 3'), measure the voltage between the second and fourth contact point (2', 4'), and calculate the conductance of the sample to be tested according to the Vanderbilt equation Rate σ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com