Energy-saving fuel gas oven tool

A gas cooker and combustion-supporting air technology, which is applied to household stoves, heating fuels, household appliances, etc., to achieve a healthy working environment and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

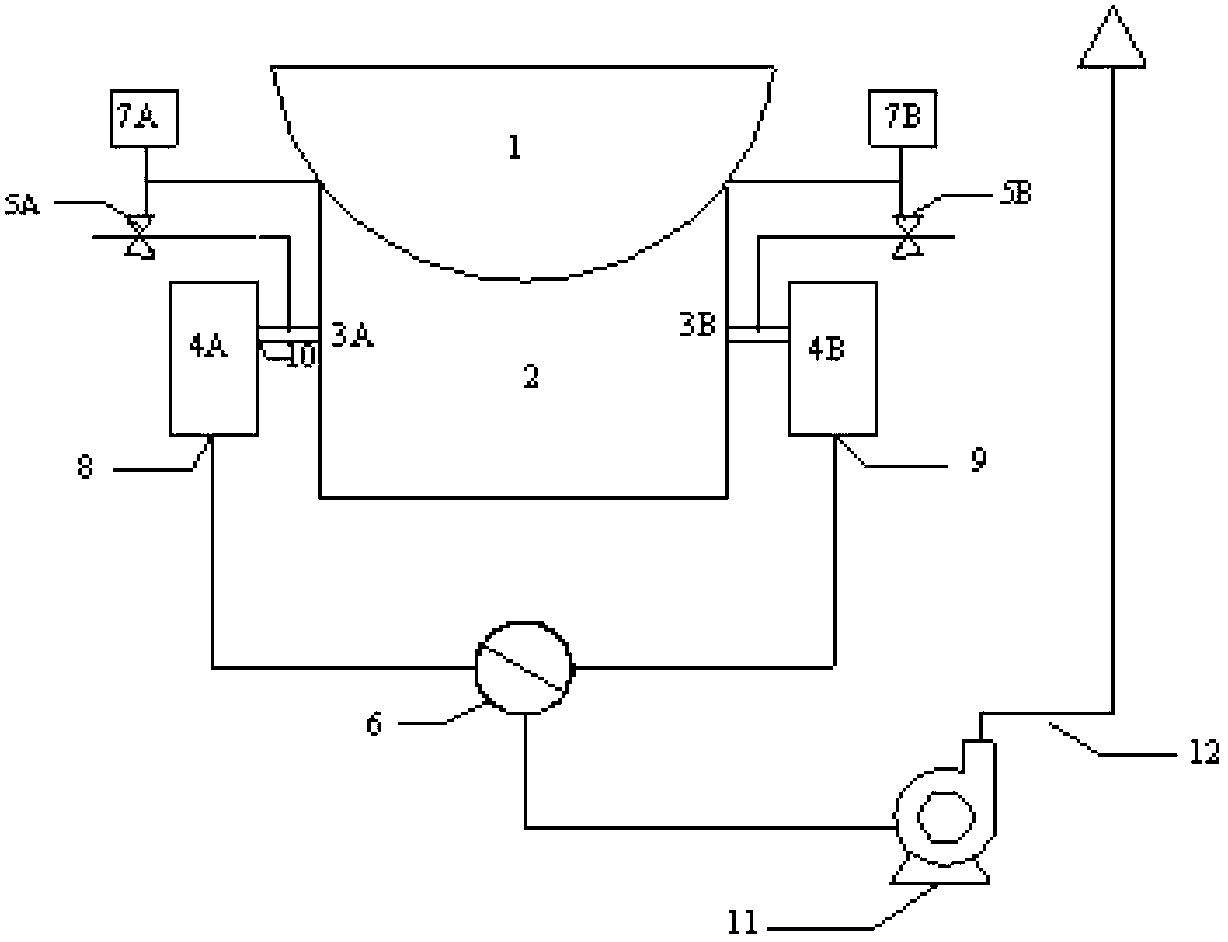

[0012] Its preferred specific implementation is as figure 1 As shown, it includes a pot 1, a furnace body 2, a regenerative burner 3A and 3B, a regenerator 4A and 4B, a gas flow control valve 5A and 5B, a reversing control valve 6, a temperature control adjustment device 7A and 7B, Induced fan 11, exhaust flue 12.

[0013] The combustion air at normal temperature enters the regenerator 4A through the reversing valve 6 and the low-temperature air inlet 8 to absorb heat and generate high-temperature air above 600°C. As combustion air, it is sent to the combustion chamber in the stove body 2 to participate in combustion, and the gas passes through the gas control valve. 5A enters, is ignited by the burner 3A and burns in the combustion chamber, and the pot body 1 is heated. The heating temperature of the pot body can be controlled by the temperature control regulator 7A. At this time, the burner 3B and the gas control valve 5B are closed. After combustion, high-temperature flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com