Installation method for steel reticulated shell and cable dome combined structure

An installation method and a combined structure technology, applied in building construction, building material processing, construction, etc., can solve the problems of high installation cost, long construction period, and difficult construction, so as to save construction period, save cost, reduce effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

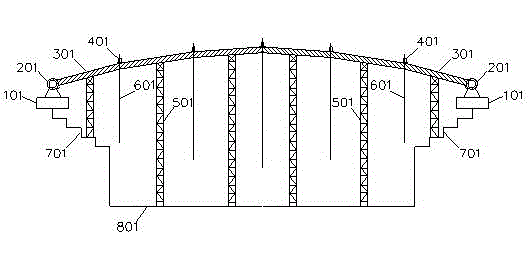

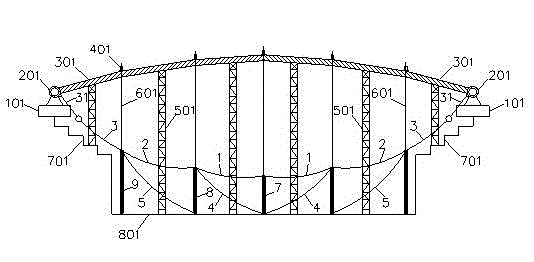

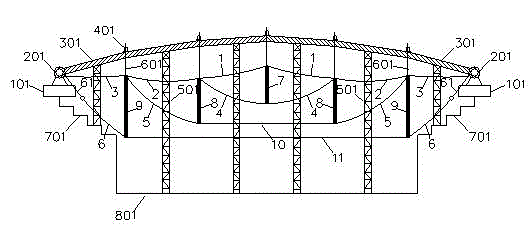

[0024] As shown in the figure, in the figure: inner ring notches 1, middle notches 2, outer notches 3, inner notches 4, middle notches 5, outer notches 6, center struts 7, middle struts 8, outer Ring support rod 9, middle ring cable 10, outer ring cable 11, ridge cable traction cable 31, oblique cable traction cable 61, outer ring beam 101, support 201, structural skeleton 301, lifting equipment 401, mounting bracket 501, lifting cable 601, stand 701, ground 801.

[0025] An installation method for a combined structure of a steel reticulated shell and a cable dome. First, according to the layout of the structure, an installation bracket is set in the middle of the site, and some rods of the steel reticulated shell are installed to form a temporary stable structural system, and then the steel reticulated shell is installed The upper part is equipped with multi-point synchronous lifting equipment, which connects the inner ring cable system of the ridge cable network with the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com