Method for producing fuel ethanol by fermenting corncob processing residue

A technology of fuel ethanol and corn cob, applied in the direction of microorganism-based methods, biofuels, biochemical equipment and methods, etc., capable of solving problems such as low ethanol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

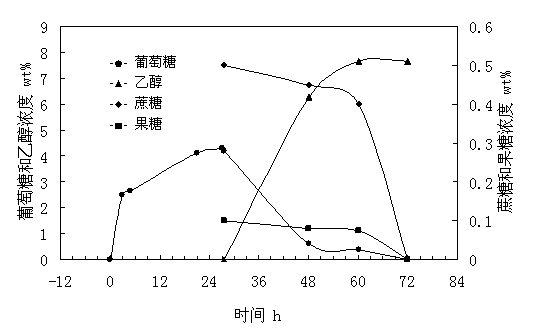

[0022] Take 100 g of corn cob processing residue (75% water content, 63% fiber content in the dry basis of corn cob processing residue), add appropriate amount of NaOH to adjust the pH to 5.0, add 6.3 g of compound enzyme preparation and 170 g of water, and put it in 1L glass for reaction In the tank, hydrolyze at 150 rpm and 50 ℃. Add 100 g of corncob processing residue at 3 h, 5 h and 21 h, respectively. After 27.5 hours, lower the temperature to 35°C, insert the cultured heat-resistant Saccharomyces cerevisiae FE-B, the amount of yeast introduced is 1‰ (the ratio of dry yeast mass to the system), and start to add molasses to the system after 28 hours (The total sugar concentration of molasses is 52.69%), the flow acceleration rate is 3.7 g / h, the feeding time is 28h-60h, and a total of 118.4 g molasses is added to the system. Results After 72 h, the ethanol concentration in the simultaneous saccharification and fermentation system of xylose residue was 9.7% v / v (concentrat...

Embodiment 2

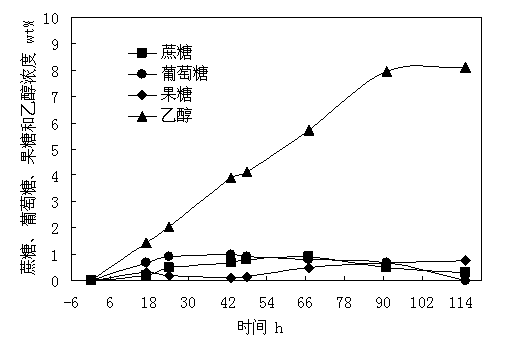

[0024]The co-fermentation experiment of corncob processing residue and molasses was carried out in a 5L fermenter. Take 1000 g of corn cob processing residue (75% water content, 63% fiber content in dry basis of corn cob processing residue), add an appropriate amount of NaOH to adjust the pH to 5.0, add 100 g of compound enzyme preparation and 1700 g of water, and put it in 5 L for fermentation Into the tank, insert the cultured temperature-resistant Saccharomyces cerevisiae FE-B, the amount of yeast added is 1 wt‰ (the ratio of the dry yeast mass to the system), and the simultaneous saccharification and fermentation are carried out at 150 rpm and 42 °C. At 16 h and 24 h, 750 g and 250 g of corncob processing residue were added twice, respectively. At 0 h, molasses (total sugar concentration: 52.69 %) was added to the system, the flow acceleration rate was 3.7 g / h, and the feeding time was from 0 h to 96 h. A total of 996 g of molasses was added to the system. Results After 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com