Polystyrene high-gloss toughening color master batch and preparation method thereof

A technology of polystyrene and color masterbatch, applied in the field of polystyrene high gloss and toughening color masterbatch and its preparation, can solve the problems of lower average molecular weight, limited application field, lack of gloss, etc., and achieves improvement of toughness and surface gloss. efficiency, expanding the scope of application, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below.

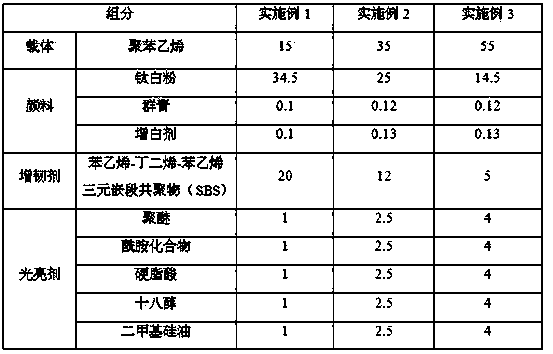

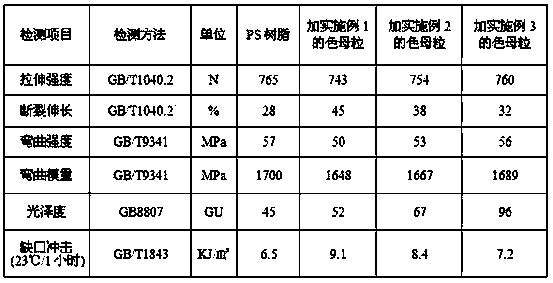

[0018] The raw material composition and parts by weight of the polystyrene high-gloss toughening masterbatch of each embodiment of the present invention are shown in the following table:

[0019]

[0020] The preparation method of the polystyrene high-gloss toughening color masterbatch of each embodiment of the present invention comprises the following steps:

[0021] 1) Add the pigment, coupling agent, surfactant and brightener to the high-speed mixer according to the ratio of raw materials and mix evenly; adding coupling agent and surfactant is to disperse the pigment;

[0022] 2) Then add polystyrene and toughening agent into the high-speed mixer according to the raw material ratio, and mix evenly with the mixed material obtained in step 1);

[0023] 3) Add the mixed material obtained in step 2) into a twin-screw extruder for kneading and extrusion, and then cool, pelletize and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com