Method for manufacturing crude melt of glass raw materials and method for manufacturing optical glass

A technology of glass raw materials and manufacturing methods, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve problems such as optical glass coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

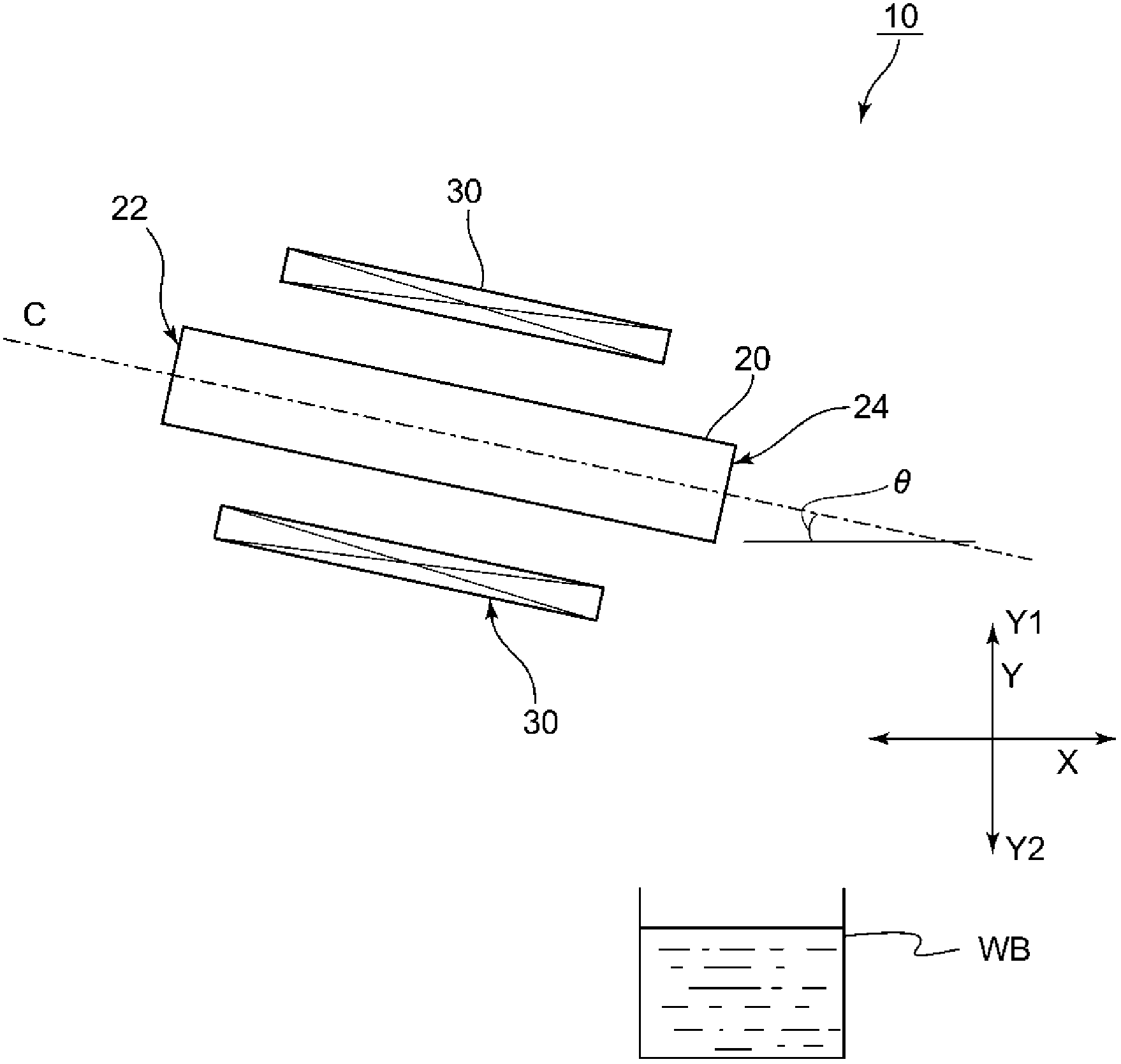

[0089] -Raw material melting furnace-

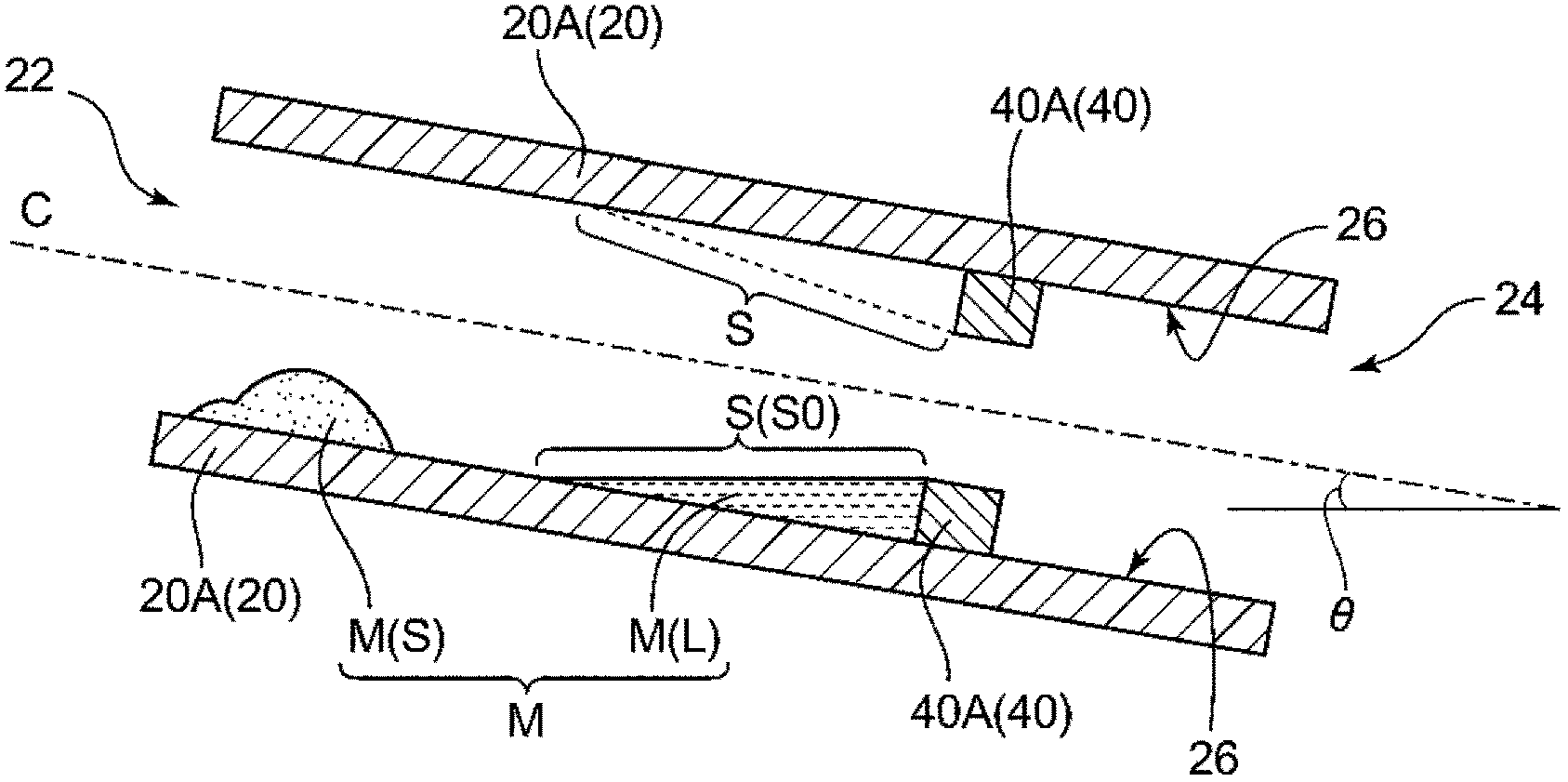

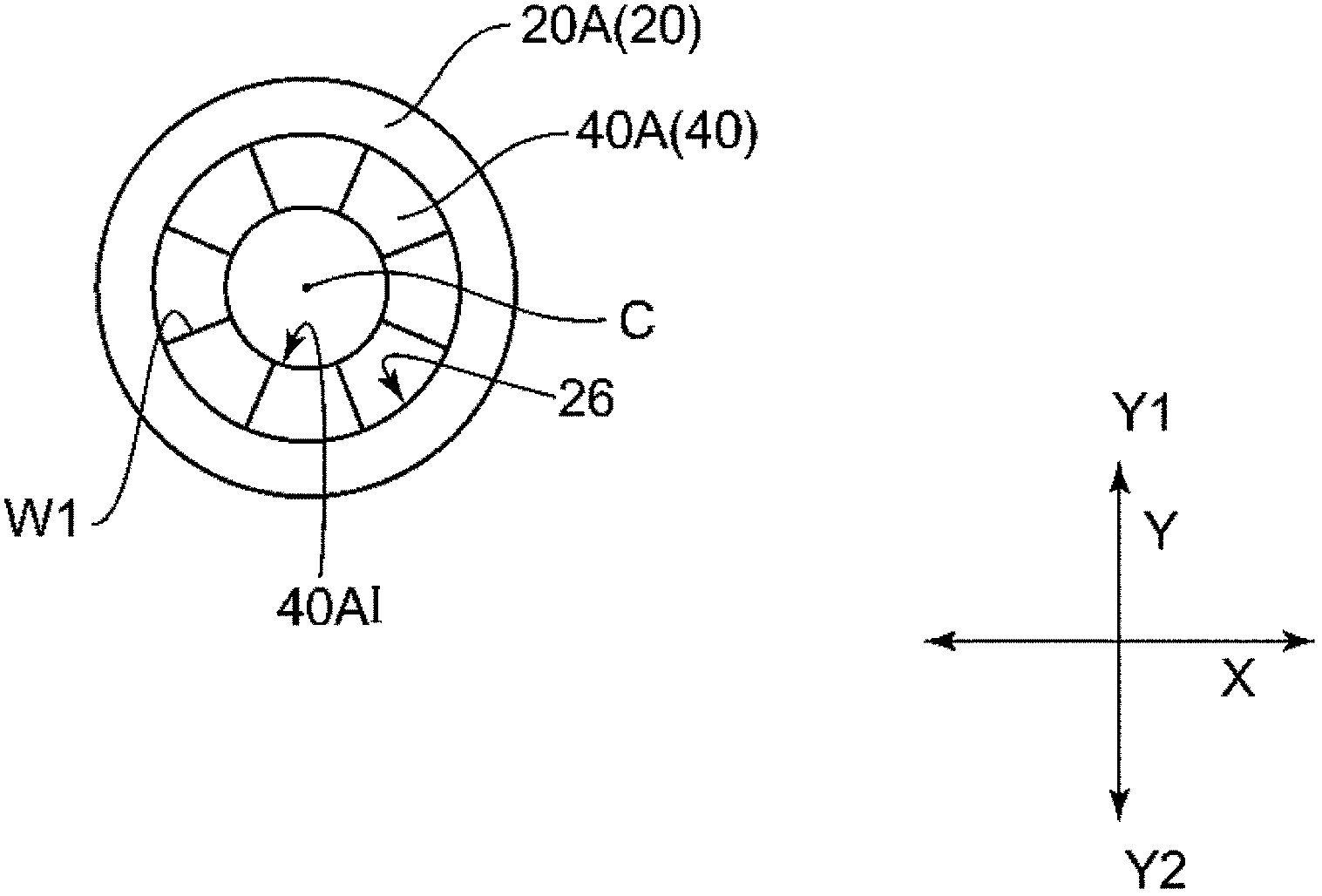

[0090] As a raw material melting furnace 10, a cylindrical tube 20 is used image 3 structure shown. All the constituent materials of the cylindrical tube 20B and the components disposed therein are made of quartz glass. Here, the dimensions and shape of the cylindrical tube 20B are: length 100 cm, outer diameter 10 cm, and inner diameter 8 cm, and the stagnation part forming member 40B is a ring-shaped member with a thickness of 5 cm, an outer diameter of 8 cm, and an inner diameter of 6 cm. After eighth equal parts, the shape is trimmed appropriately for easy placement in the cylindrical tube 20B. The gap between the two adjacent retention portion forming members 40B arranged in the cylindrical tube 20B is about 1 mm. In addition, the block member 50 is produced by appropriately cutting an annular member having the same thickness as the annular member used for producing the stagnation portion forming member 40B. In addition, the st...

Embodiment A2

[0112] Use the following raw material melting furnace 10, that is, except that instead of using the blocking member 60 at the same time image 3 structure shown in the Figure 4 The shown structure is the raw material melting furnace 10 having the same structure as the raw material melting furnace 10 used in Example A1 except for the structure inside the cylindrical tube 20 of the raw material melting furnace 10 . Here, the size and shape of the cylindrical tube 20C are the same as those of the cylindrical tube 20B used in Example A1. In addition, the stagnation portion forming member 40C is formed by quartering an annular member made of the same material as the cylindrical pipe 20C at equal intervals in the circumferential direction, and then trimming its shape appropriately for easy placement in the cylindrical pipe 20C. part. Moreover, 40 C of stagnation part formation members were arrange|positioned at the position of about 20 cm from the side of the outlet 24 of 20 C of...

Embodiment A3

[0122] Instead of the cylindrical tube 20B used in Example A1, a semi-cylindrical tube ( Figure 6 Shown trough member 100). The trough member 100 is the same as the cylindrical pipe 20B in other dimensions and constituent materials except for the point that the cylindrical pipe 20B is divided into two. In addition, the number of stagnation portion forming members 40B and block members 50 arranged in the cylindrical tube 20B is reduced to half, as shown in Figure 6The configuration shown is on the inner peripheral surface of the trough member 100 . And except that the tank-shaped member 100 was not rotated, the blocking member 60 was arranged in the stagnation part in the same manner as in Example A1, and cullet was produced under the same conditions as in Example A1. As a result, λ70 showed substantially the same value as that of Example A1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com