Concentrating and dry stacking system of tailings and dry stacking method

A technology of tailings and dry stacking, applied in the direction of solid separation, etc., can solve the problems of loss of life and property of downstream people, large area of tailings pond, loss of surrounding water of dressing plants, etc. Low investment and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

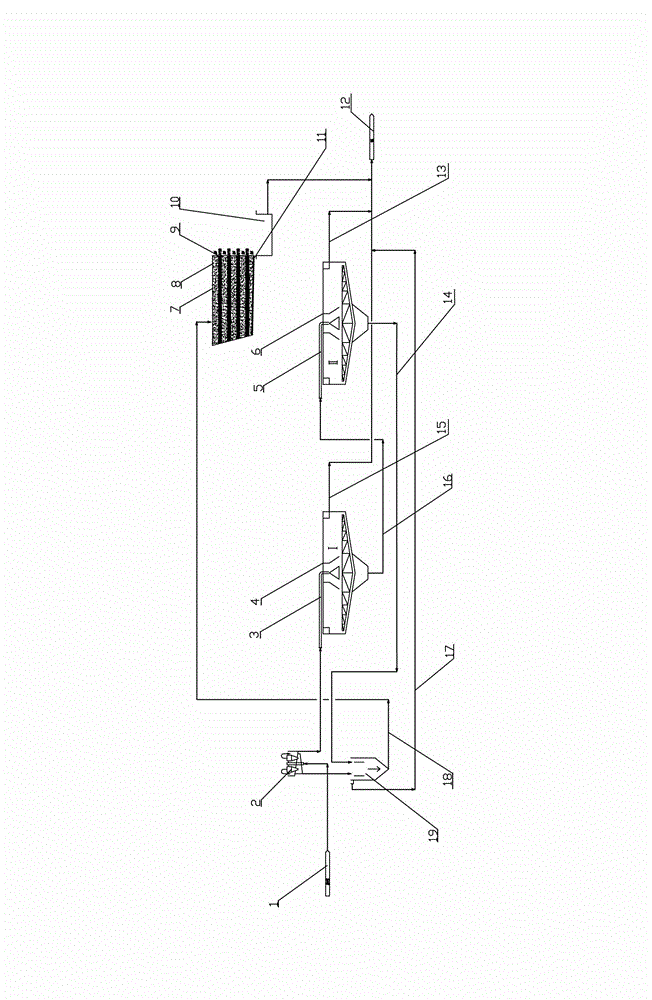

[0021] Such as figure 1 As shown, the tailings concentration and dry stacking system of the present invention includes a tailings concentration system, a delivery pipeline and a tailings and gravel storage site, and is characterized in that:

[0022] The tailings thickening system is composed of a cyclone group 2, a concentration pool I4 and a concentration pool II6 arranged on the side of the cyclone group 2, and a paste tailings concentration pool 19 arranged at the lower part of the cyclone group 2,

[0023] The ore feeding pipe 3 of the concentration pool I4 is connected with the overflow outlet pipe of the cyclone group 2, the overflow outlet pipe 15 of the concentration pool I4 is connected with the circulating water pipeline 12, and the bottom of the concentration pool I4 flows out of the ore pipe 16 is connected with the ore feeding pipe 5 of the concentration pool II6, the overflow outlet pipe 13 of the concentration pool II6 is connected with the circulating water pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com