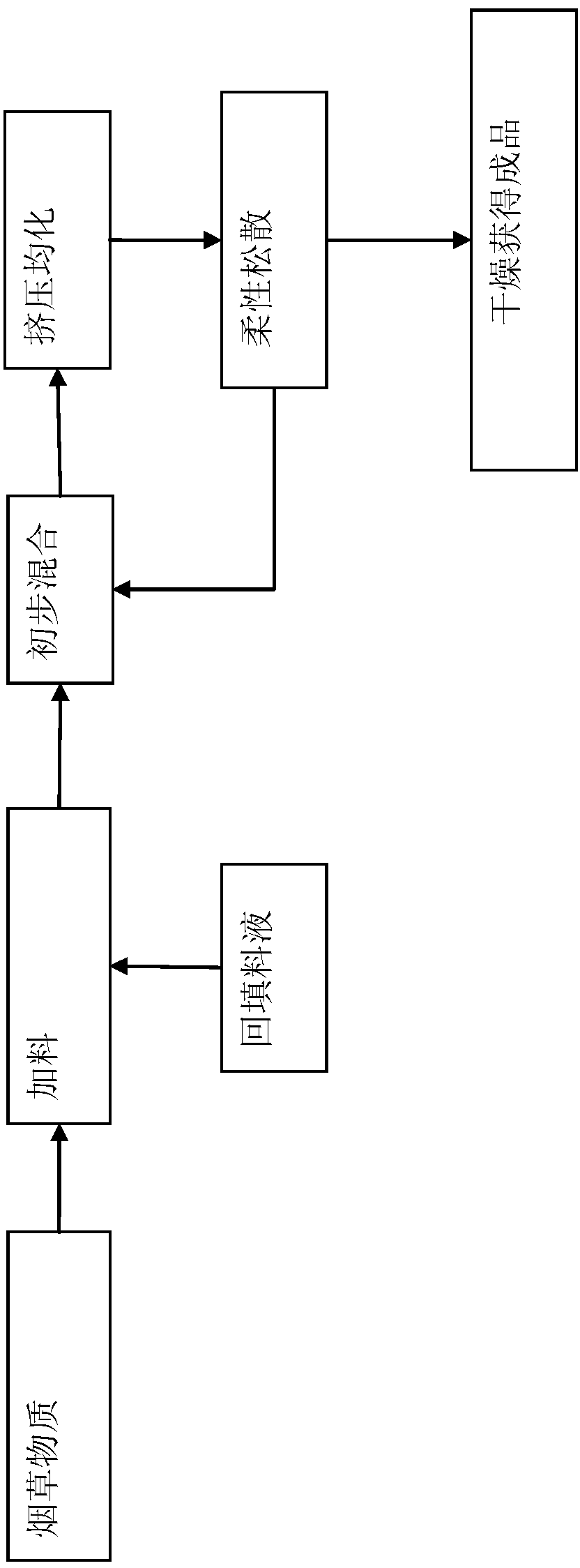

Method for homogenizing and mixing tobacco material and backfill liquid

A technology of backfill and tobacco, which is applied in the field of tobacco technology, can solve problems such as large quality differences and affecting the stability of cigarette quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

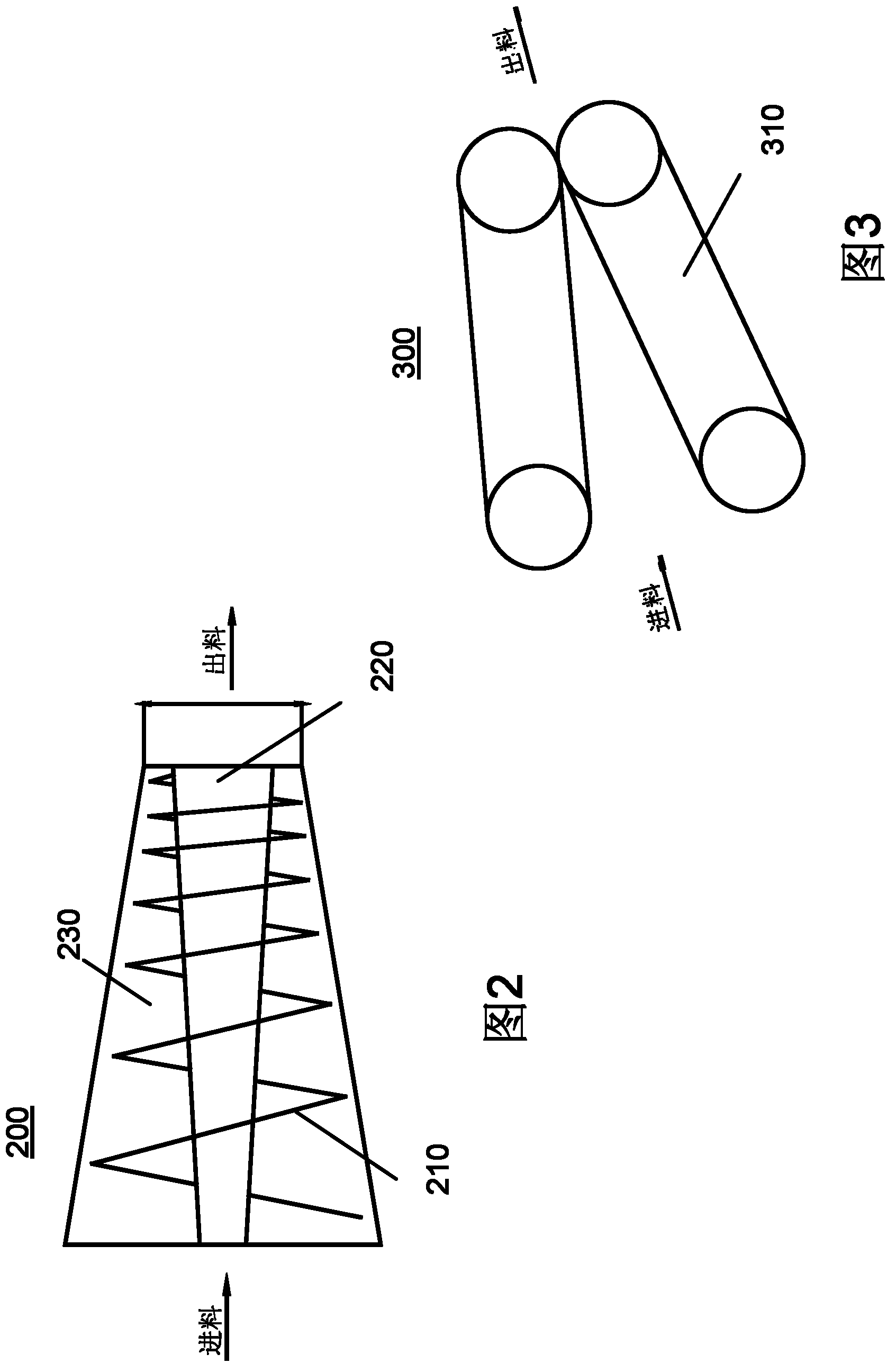

Embodiment 1

[0040]Embodiment 1: After water extraction and solid-liquid separation, the cut tobacco stems have a water content of about 70%, and are dried to about 20% of the moisture by airflow drying equipment, and then the weight of the cut stems is used in the feeding device: the weight of the liquid = Spray 45% solid content of cut stem additives at a ratio of 1:1, the actual backfill rate is 36%, and the water content after backfill is 37.5%. The distribution is relatively even. The cut stems homogenized by the drum are sent to a single-screw continuous extrusion device for extrusion. The compression ratio of the screw extrusion is 3:1, and the rotation frequency of the screw is 25 Hz. After the extruded material is loosened by the flexible loosening device, it is found that the color is uniform. After continuous sampling and testing, the fluctuation value of the backfill rate is less than 1.5%.

Embodiment 2

[0041] Embodiment 2: After water extraction and solid-liquid separation, the cut tobacco stems have a water content of about 70%, and they are dried to about 18% of moisture by airflow drying equipment, and then the weight of the cut stems is used in the feeding device: the weight of the liquid = The ratio of 1:1.5 was sprayed with 45% solid content of cut stem additives, the actual backfill rate was 45.8%, and the water content after backfill was 40.2%. The distribution is relatively even. The cut stems homogenized by the drum are sent to a single-screw continuous extrusion device for extrusion. The compression ratio of the screw extrusion is 3:1, and the rotation frequency of the screw is 35 Hz. After the extruded material is loosened by the flexible loosening device, it is found that the color is uniform. After continuous sampling and testing, the fluctuation value of the backfill rate is less than 1%.

Embodiment 3

[0042] Embodiment 3: After the shredded tobacco is extracted with water and separated from solid and liquid, the moisture content is about 72%, and it is dried to about 30% moisture by airflow drying equipment, and then the weight of shredded tobacco: the weight of feed liquid = 1:0.5 is used in the feeding device The ratio of spraying 40% cut tobacco additives with solid content, the actual backfill rate is 22%, and the moisture after backfill is 40%. After homogenizing by the drum, it is found that some cut tobacco color is lighter microscopically, but the distribution is relatively uniform. The cut stems homogenized by the drum are sent to the upper and lower copper bar chain trapezoidal continuous extrusion devices for extrusion, and the extrusion compression ratio is set to 2.8:1. After the extruded material is loosened by the flexible loosening device, it is found that the color is uniform. After continuous sampling and testing, the fluctuation value of the backfill rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com