Silicon ingot tipping gear

A turning device and silicon ingot technology, applied in the direction of hoisting device, hoisting device, etc., can solve the problems of high material damage rate, unguaranteed safety, low work efficiency, etc., and achieve the effect of smooth turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

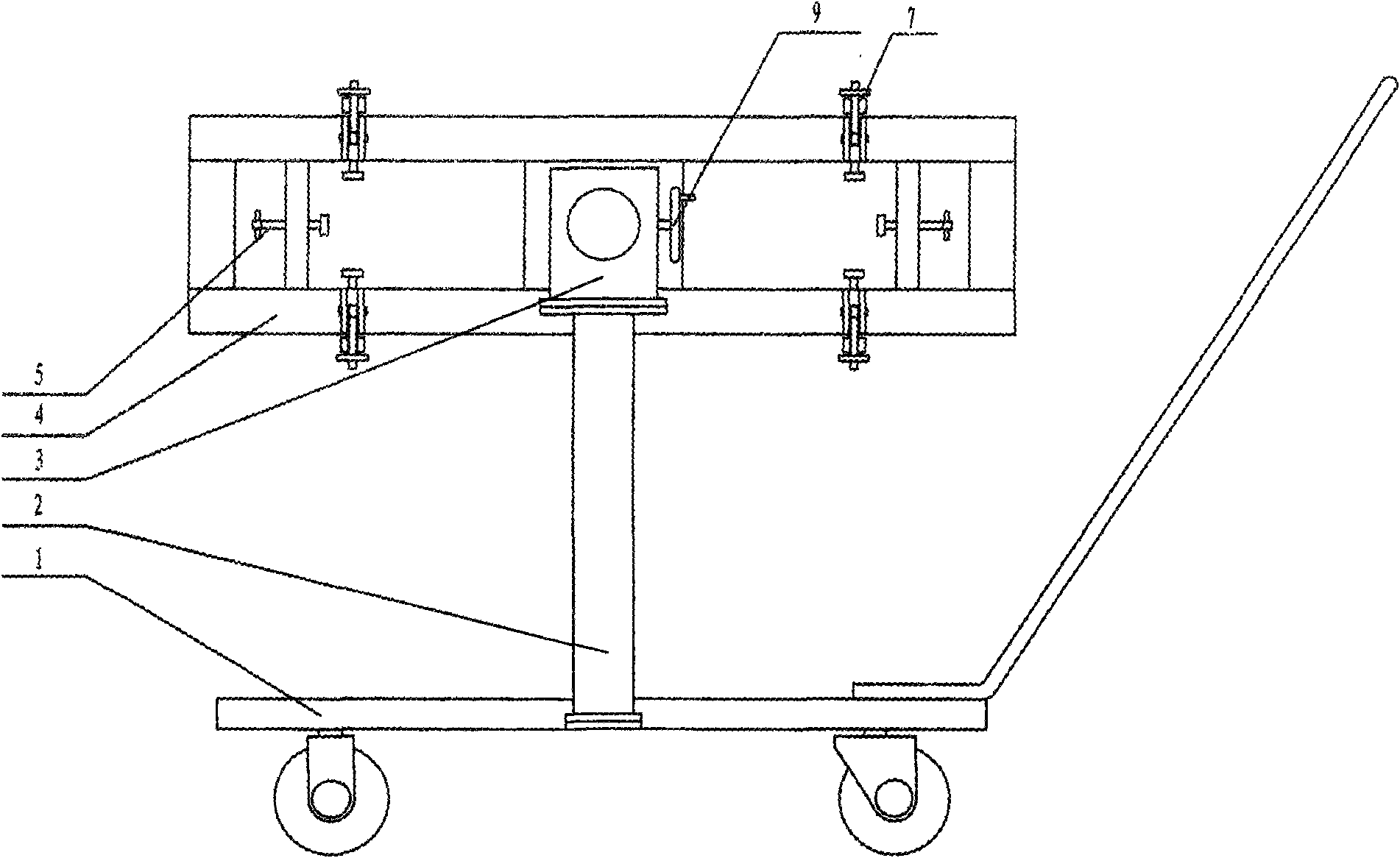

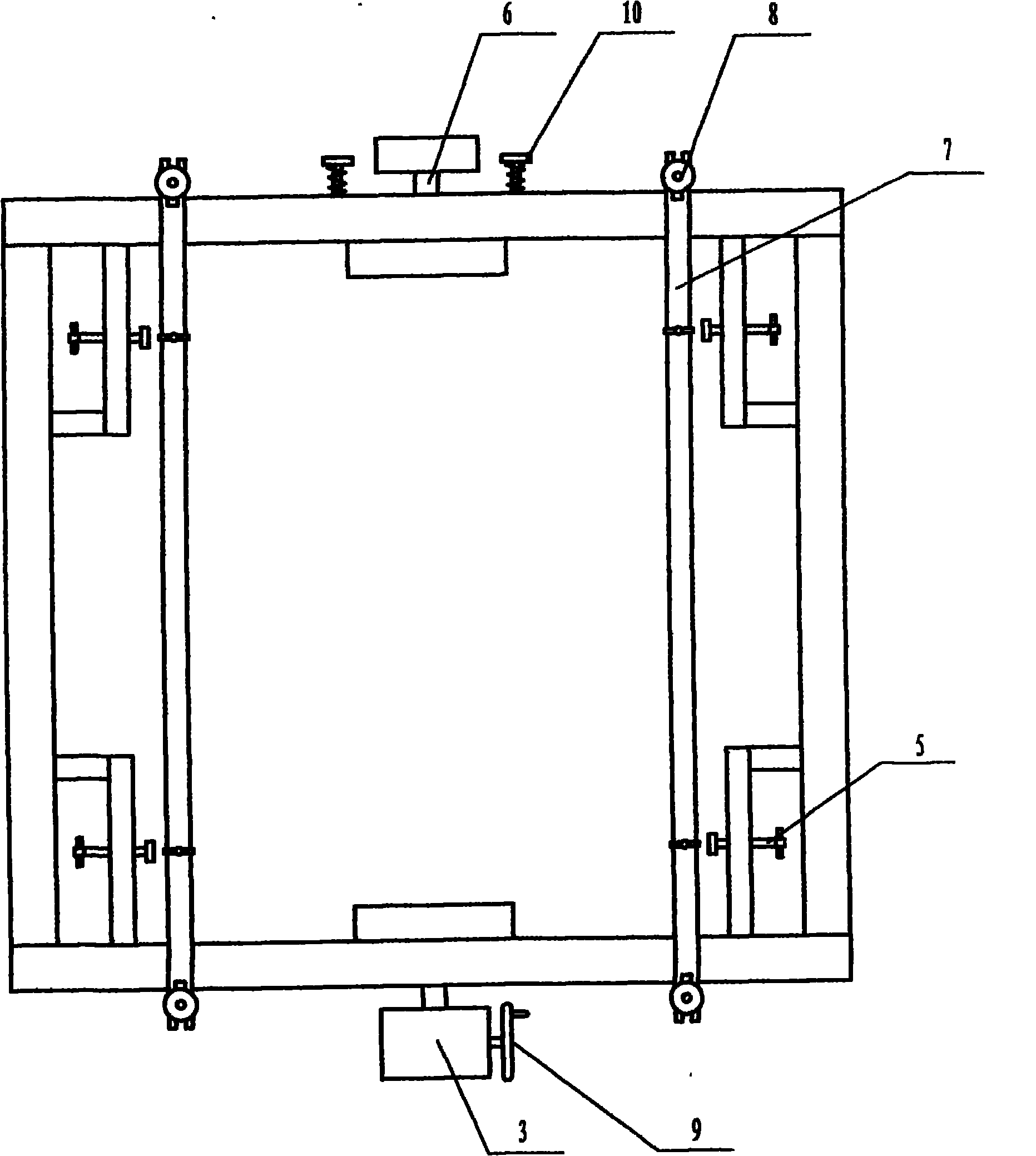

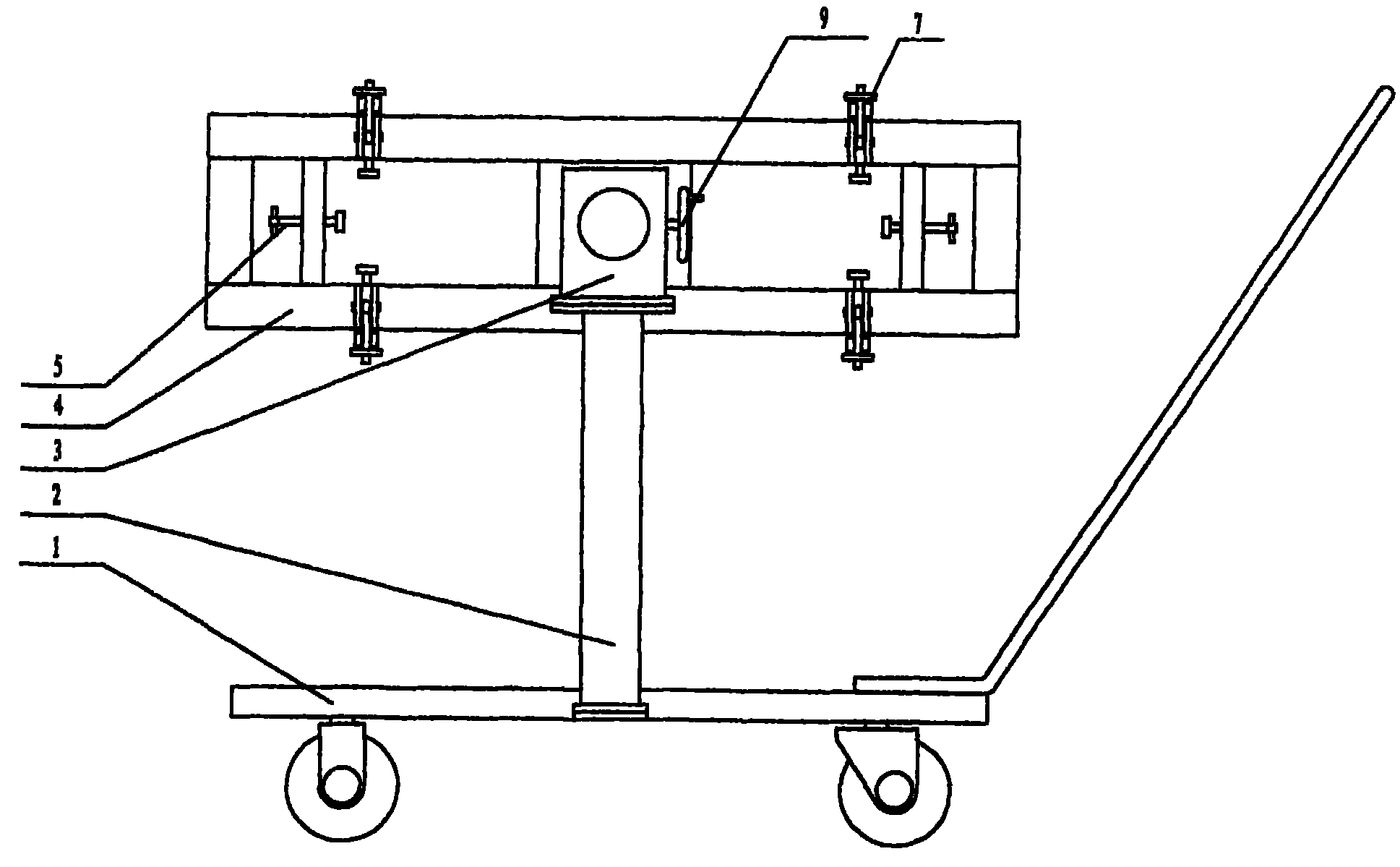

[0010] Such as figure 1 and figure 2 As shown, a silicon ingot turning device includes a loading trolley 1, a bracket 2 and a turning bracket 4, the bottom of the bracket 2 is fixed on the loading trolley 1, and the turning bracket 4 is movably connected with the bracket 2 through a rotating shaft 6, and the rotating shaft 6. One or two rotating shaft structures can be used. When two rotating shafts are used, each rotating shaft is respectively located at both ends of the bracket 2. When one rotating shaft is used, the whole body passes through the bracket 2, and the end of one side of the rotating shaft 6 extends out of the bracket 2. The outside is connected with the rotating mechanism. Described turning mechanism is made up of reduction box 3 and turning over handwheel 9, and turning over handwheel 9 is located on the reduction box 3 and links to each other with rotating shaft 6 through the reduction box 3 internal gears. The front and back sides of the overturning brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com