Electric connector and connecting piece structure thereof

A technology for electrical connectors and connectors, which is applied in the installation, connection, and fixed connection of connecting components, which can solve the problems of affecting the effect of reflow soldering, production trouble, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

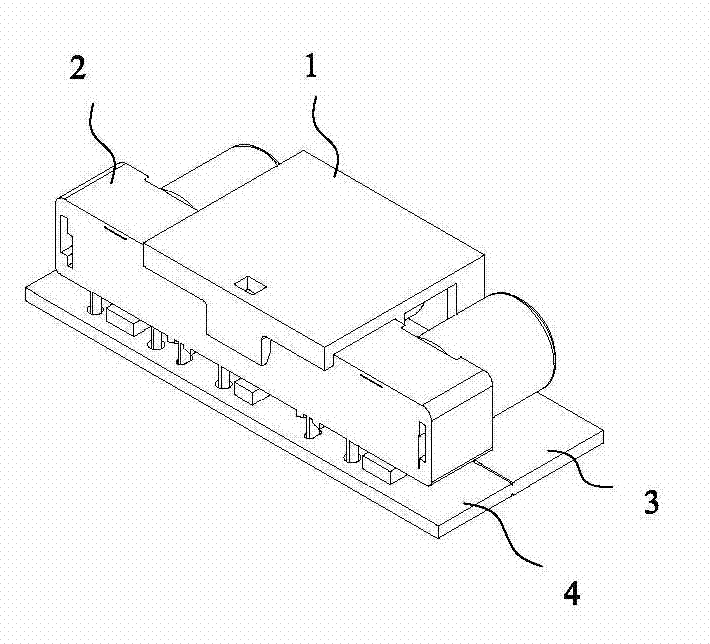

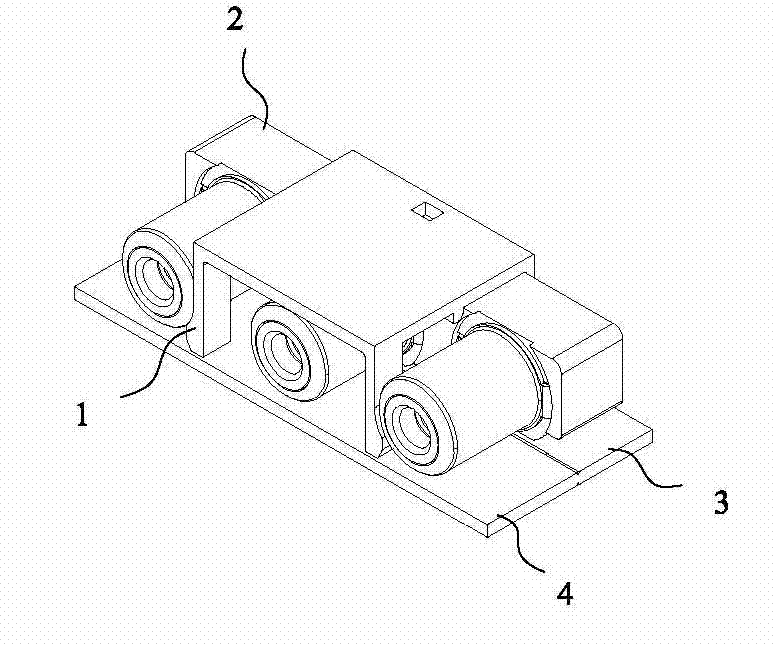

[0051] Please refer to Figure 4 to Figure 8 As shown, it has shown the specific structure of the preferred embodiment of the present invention. The present embodiment takes the audio and video socket as an example to illustrate the specific structure, but this design structure can not only be used on the audio and video socket, but also Used on other electrical connectors.

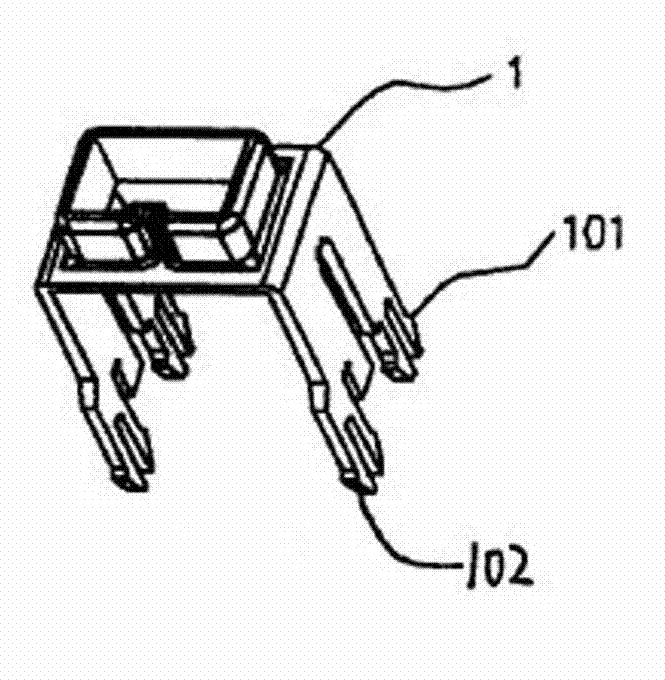

[0052]The audio-video socket of this embodiment includes a connector body and a connector 40, the connector body is composed of an insulating base body 10 and a plurality of audio-video interfaces 20 mounted on the insulating base body 10, the audio-video interface 20, one end extends out of the insulating base body 10, and the other end is embedded in the insulating base body 10, and the audio-video interface 20 has a conductive terminal 30 embedded in the insulating base body 10, and the connector 40 is fixed on the insulating base body 10, used to fix the main body of the connector on the PCB 50, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com