Method of controlling copper-film etching process and method of regenerating copper-film etchant composition

A control method and etching solution technology, applied in spectrometry/spectrophotometry/monochromator, semiconductor/solid-state device manufacturing, optical radiation measurement, etc., can solve the problem of difficult real-time analysis and simultaneous real-time automatic analysis of copper film Changes in the composition concentration of the etching solution, the concentration of copper ions, and the inability to obtain the composition of the copper film etching solution in real time, the treatment and management of the composition of the copper film etching solution, etc., to achieve the effects of saving raw materials, saving manufacturing costs, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

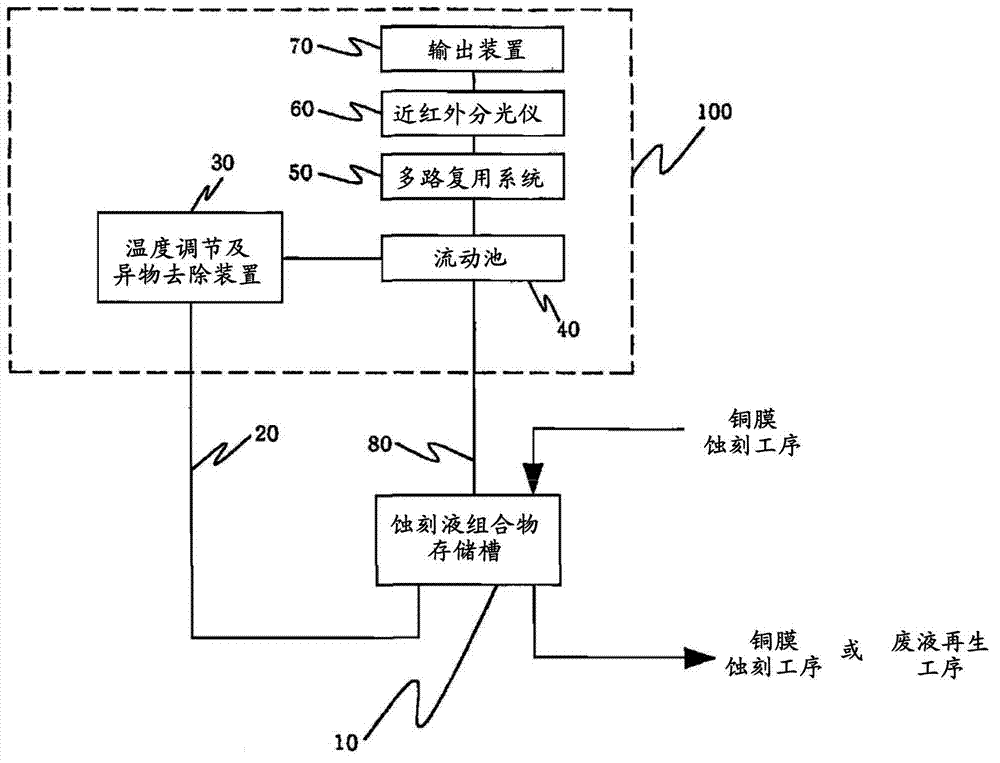

[0069] In order to evaluate the process suitability of the analysis system that has utilized the near-infrared spectrophotometer, as shown in Table 1 below, the concentration of the following etching solution composition components for copper film etching was changed, and at the same time, using figure 1 The shown copper film etching process control system performs real-time measurement, and the results of the measured component analysis values are listed in Table 1. At this time, the near-infrared absorbance was measured using a 10 mm quartz cell, and the measurement was repeated five times for each sample and averaged.

[0070] Table 1

[0071] composition

salt composition

acid component

ammonium salt

Deionized water

Copper ions*

Concentration measurement range

2~3% by weight

0.2~0.8% by weight

0.2~0.8% by weight

94~97% by weight

0~3,500ppm by weight

0.998

0.9999

0.99...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com