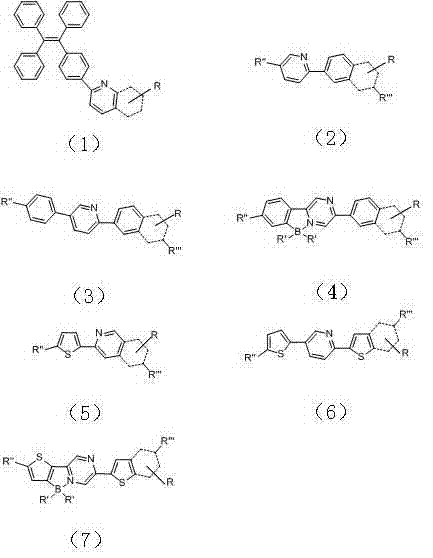

Boron-containing luminescent material and its preparation method and use

A technology of luminescent materials and raw materials, applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problem of no fluorescence phenomenon, and achieve the effects of good optical properties, stable optical materials, and stable generated compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

[0051]Dissolve the raw material (0.45g, 1mmol) with the structural formula (1-1) in 100ml of dichloromethane, add diisopropylethylamine (0.17ml, 1mmol) dropwise, and add tribromo Boronide (2.94ml.3mmol, 1M). Stir at room temperature for 24 hours. After the reaction, the color of the reaction solution is darkened and poured into water, extracted with dichloromethane, washed the organic layer with water, dried with anhydrous magnesium sulfate, filtered, and evaporated to obtain the primary product. Dissolve the obtained primary product in 100ml of toluene, add trimethylaluminum (1.08ml, 2.2mmol, 2M) at room temperature, react for 3 hours at room temperature, pour into water, extract with dichloromethane, wash the organic layer with water, anhydrous sulfuric acid Dry over magnesium, filter, and rotavap to give an intermediate product. The intermediate product was loaded into a column with a mixture of petroleum ether and dichloromethane (volume ratio of the mixture =...

Embodiment 2

[0056]

[0057] Dissolve the raw material (0.50g, 1.2mmol) with the structural formula (1-2) in 100ml of dichloromethane, add diisopropylethylamine (0.244ml, 1.4mmol) dropwise, and add Boron tribromide (4.80ml. 4.8mmol, 1M). Stir at room temperature for 24 hours. After the reaction, the color of the reaction solution is darkened and poured into water, extracted with dichloromethane, washed the organic layer with water, dried with anhydrous magnesium sulfate, filtered, and evaporated to obtain the primary product. Dissolve the obtained primary product in 100ml of toluene, add triethylaluminum (1.50ml, 3 mmol, 2M) at room temperature, pour it into water after reacting at room temperature for 4 hours, extract with dichloromethane, wash the organic layer with water, anhydrous magnesium sulfate Dry, filter, and rotavap to give an intermediate product. The intermediate product was packed into a column with a mixture of petroleum ether and dichloromethane (volume ratio of the mix...

Embodiment 3

[0062]

[0063] Dissolve the raw material (0.61g, 1mmol) with the structural formula (2-1) in 150ml of dichloromethane, add diisopropylethylamine (0.52ml, 3mmol) dropwise, and add tribromo Boronide (8.00ml, 8mmol, 1M). Stir at room temperature for 24 hours. After the reaction, the color of the reaction solution is darkened and poured into water, extracted with dichloromethane, washed the organic layer with water, dried with anhydrous magnesium sulfate, filtered, and evaporated to obtain the primary product. Dissolve the obtained primary product in 150ml of toluene, add trimethylaluminum (4ml, 8mmol, 2M) at room temperature, pour into water after reacting at room temperature for 3 hours, extract with dichloromethane, wash the organic layer with water, and dry over anhydrous magnesium sulfate. Filtration and rotary evaporation gave intermediate products. The intermediate product was packed into a column with a mixture of petroleum ether and dichloromethane (volume ratio of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com