Tobacco stems carding device

A kind of equipment and tobacco stem technology, which is applied in the fields of tobacco, paper cigarette manufacturing, application, etc., can solve the problems of improving the quality and quality of cigarettes with a ratio of filamentous stems and shreds, and achieve the goal of changing the physical shape, reducing the crushing rate, and changing the color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

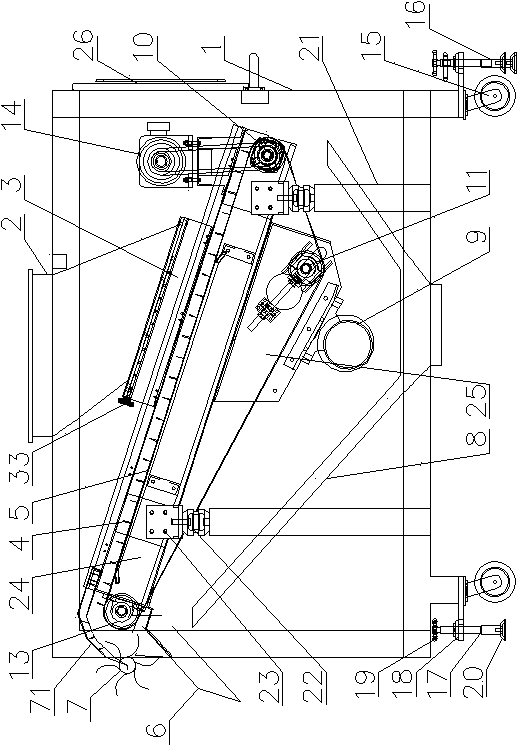

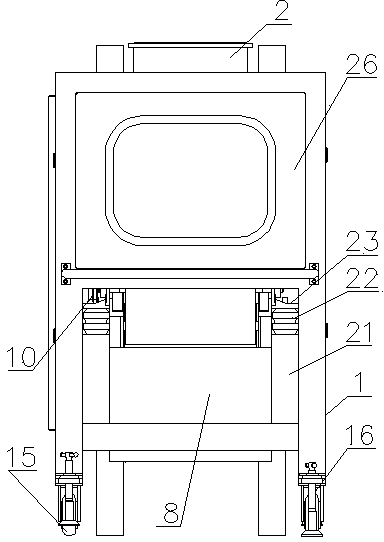

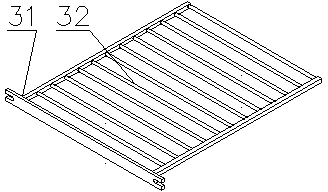

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown tobacco stem carding equipment includes a frame 1 and a feed hopper 2, a carding screen 3, a vibrating conveying mechanism and a buffer mechanism arranged sequentially on the frame 1 from top to bottom. The carding sieve 3 includes a screen frame 31 and a screen bar 32 inserted in the screen frame 31. The screen frame 31 supports the screen bars 32. The distance between the screen bars 32 is smaller than the length of the tobacco stem. The screen frame 31 is fixed by pressing the hand wheel 33 At the lower port of the feed hopper 2, the carding screen 3 is detachable and replaceable, which is convenient for cleaning and maintenance. The vibrating conveying mechanism includes an upper fixed plate 24 and a lower fixed plate 25. The two ends of the upper fixed plate 24 are respectively provided with a driving roller 10 and a driven roller 13, and the position of the driven roller 13 is higher than that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com