Film-type automatic bagging machine

A bagging machine and automatic technology, applied in horticulture, application, botany equipment and methods, etc., can solve problems such as the need for manual collars, difficult production, low bagging efficiency, etc., to achieve the change of process flow, simple operation, and improved The effect of degree of automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

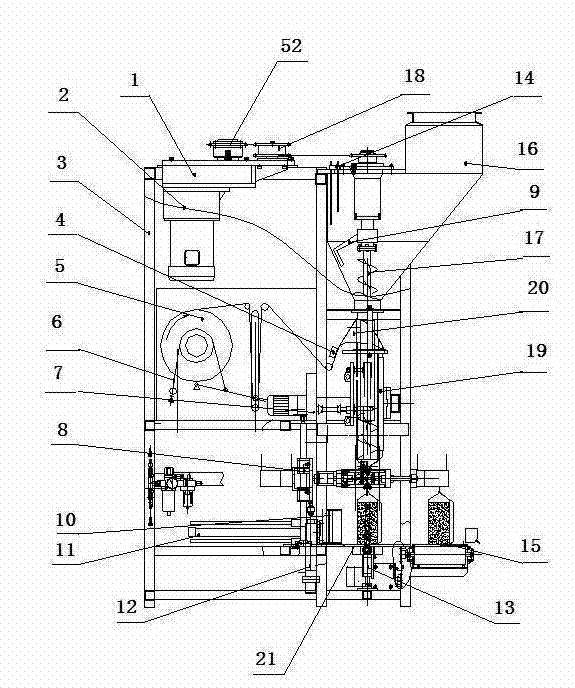

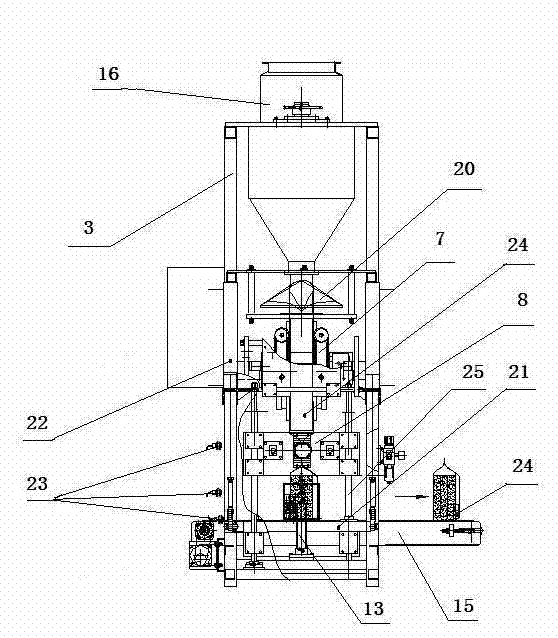

[0033] Embodiment 1, with reference to Figure 1-10 , a membrane automatic bagging machine,

[0034] The bagging machine includes a frame 3, on which a driving motor 2 is arranged on the top of the frame 3, and the driving motor 2 is connected with the feed screw 17 through the forward and reverse transmission device 1, and the forward and reverse rotation transmission device 1 is rotated by the forward rotation Composed of electromagnetic reversing clutch 52, reverse electromagnetic reversing clutch, transmission sprocket 18 and transmission chain;

[0035] Also be provided with storage hopper 16 on the top of frame 3, be provided with material level meter 14 on storage hopper 16, be provided with the feeding screw rod 17 that is supported by bearing seat inside storage hopper 16, be provided with on the feeding screw rod 17 in storage hopper 16 There is a stirring rod 9, and a feed pipe 24 set outside the feeding screw 17 is provided at the lower end of the storage hopper 1...

Embodiment 2

[0059] Embodiment 2, in the film-type automatic bagging machine described in Embodiment 1: the position detection device 23 is provided with three proximity sensors in total, upper, middle and lower.

Embodiment 3

[0060] Embodiment 3, in the film type automatic bagging machine described in Embodiment 1: a detector 4 is provided at the side of the curved surface former 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com