End part thread five-pointed-star-shaped variable-section prefabricated pipe pile and construction method thereof

A technology of prefabricated pipe piles and threads, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing the safety reserve of pile body strength, uneven subsidence of upper structures, and reducing bearing capacity, etc., to achieve increased The effect of bearing capacity, simple construction, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

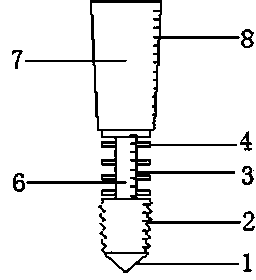

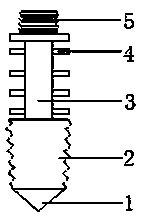

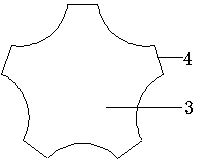

[0028] Embodiment 1: A prefabricated pipe pile with threaded five-star deformed section at the end of the present invention, its structure is as follows figure 1 As shown, the first pipe section 6 and the second pipe section 7 are included. The structure of the first pipe section 6 is as follows: figure 2 , from bottom to top, there are pile tip 1, large section section 2, ribbed section 3 and top threaded section 5. The large section section 2 is frustum-shaped with threads on the surface. equal, such as image 3 , the surface of the ribbed section has ribs 4; the cross section of the top threaded section 5 is circular.

[0029] Such as Figure 4 , the second pipe joint 7 is in the shape of an inverted truncated cone, the truncated cone has a central through hole 10, the lower section of the central through hole is provided with an internal thread section 9, the surface of the truncated cone is smooth, and a scale line 8 is provided, and the scale line is marked with a br...

Embodiment 2

[0030] Embodiment 2: Apply the construction method of a prefabricated pipe pile with threaded five-star shape at the end provided in Embodiment 1 of the present invention, including the following construction steps:

[0031] (1) Level the site and put the static pressure pile driver 11 in place, such as Figure 5 shown.

[0032] (2) Lifting of prefabricated piles: use a crane 12 to lift the first pipe joint 6 into the pile pressing box 13, so that the pile tip 1 is vertically aligned with the center of the pile position, such as Figure 6 as shown in a.

[0033] (3) Press into the first pipe joint 6: press the first pipe joint 6 into the ground with the pile pressure hydraulic cylinder of the pile pressure box 13 . Such as Figure 6 As shown in b, the pile is clamped by using the force-increasing principle of the wedge splitting of the chuck box, and the pile is pressed into the ground with the pile-pressing hydraulic cylinder. The pile-pressing stroke is 1m each time, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com