Efficient compound additive of methanol gasoline and preparation method thereof

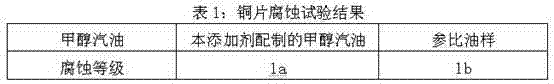

A compound additive, methanol gasoline technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of imperfect additive performance, high engine noise, blockage of fuel injection nozzles, etc., to avoid weight instability and use. Safe, corrosion-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: This high-efficiency composite additive for methanol gasoline is prepared according to the following weight ratio and steps at normal temperature and pressure:

[0023] Weight percentage of raw materials: isopropanol 14%; isooctanol 56%; methyl tert-butyl ether 5%; tetrahydrofuran 5%; xylene: petroleum xylene 10%; metal corrosion inhibitor: N,N' dialkyl Aminomethylene benzotriazole 0.3%; Rubber swelling inhibitor: 2,6-Dimethylmorpholine 0.3%; Detergent and dispersant: Polyethylene glycol alkyl ether 8%; Anti-wear lubricant: Sulfurized olefin cottonseed oil T405 1.2%; antioxidant: 2,6-di-tert-butyl-p-cresol 0.2%. The total mass percentage content of o-xylene, m-xylene and p-xylene in the petroleum xylene is 98%.

[0024] Preparation:

[0025] (1) Add isopropanol, methyl tert-butyl ether, tetrahydrofuran, and xylene to the container containing iso-octanol at one time;

[0026] (2) Add the metal corrosion inhibitor and the rubber swelling inhibitor into th...

Embodiment 2

[0029] Embodiment 2: The weight ratio and preparation method of the high-efficiency composite additive for methanol gasoline are as follows.

[0030] Raw material weight percent: isopropanol 12%; isooctanol 56%; methyl tert-butyl ether 8%; tetrahydrofuran 6%; xylene: coking xylene 8%; metal corrosion inhibitor: dimerized oleic acid 0.4%; Rubber swelling inhibitor: 2,4,6-trichloroisocyanate phenyl 0.2%; detergent and dispersant: polyisobutylene succinimide 7.6%; anti-wear lubricant: vulcanized olefin cottonseed oil T405 1.5%; antioxidant Agent: 0.3% of 2,6-di-tert-butyl-4-methylphenol. The total mass percent content of o-xylene, m-xylene and p-xylene in the coking xylene is 96%.

[0031] The method of preparation and use is the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: The weight ratio and preparation method of the high-efficiency composite additive for methanol gasoline are as follows.

[0033] Weight percentage of raw materials: isopropanol 11%; isooctanol 62%; methyl tert-butyl ether 4%; tetrahydrofuran 7%; xylene: petroleum xylene 7%; metal corrosion inhibitor: benzotriazole 0.2% ;Rubber swelling inhibitor: Dioctyl phthalate 0.3%; Detergent and dispersant: Glycol ether 7%; Anti-wear lubricant: Sulfurized olefin cottonseed oil T405 1.3%; Antioxidant: 2,6-ditert Butyl p-cresol 0.2%. The total mass percentage content of o-xylene, m-xylene and p-xylene in the petroleum xylene is 97%.

[0034] The method of preparation and use is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com