Cigarette with temperature adjustment function

A functional and cigarette technology, applied in the field of cigarettes with temperature adjustment function, can solve the problems of low cigarette release efficiency, low acceptance, and easy volatilization of flavors, so as to improve the effect of thermal distillation, improve the utilization rate, and reduce the release of harmful substances volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

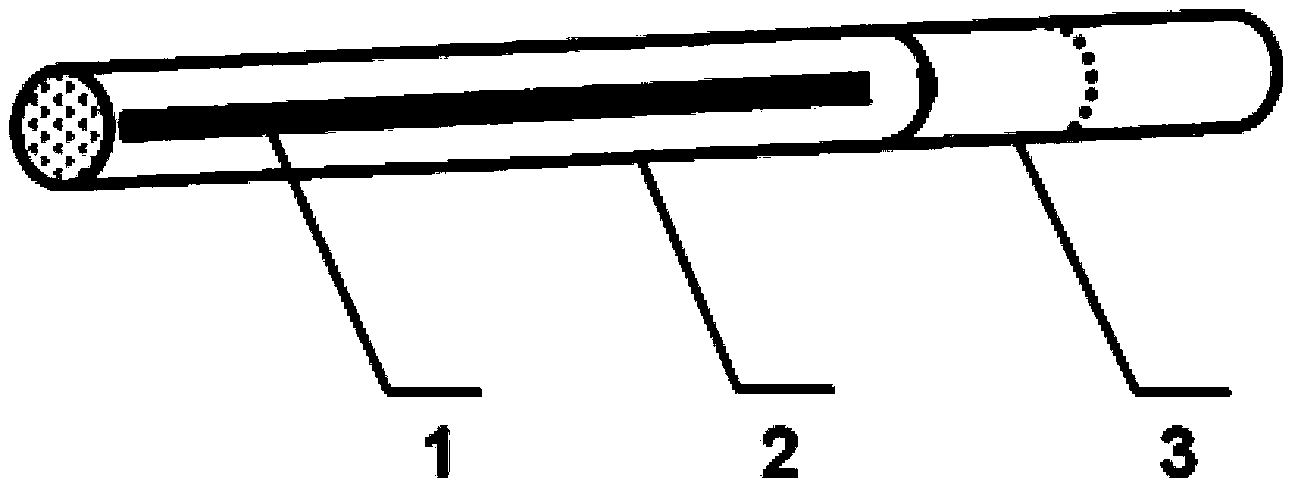

[0024] see figure 1 , the cigarette with temperature regulation function in this embodiment includes a filter rod 3, a shredded tobacco rod 2 and a thermal conductor 1 arranged in the shredded tobacco rod 2, along the longitudinal direction of the shredded tobacco rod, the thermal conductor 1 is loaded in the center of the shredded tobacco rod 2 The position, the end (near the end of the filter rod) is 4mm away from the end face of the filter rod, and the head end (ignition end) is 2mm away from the end face of the tobacco rod. The thermal conductor in this embodiment is cylindrical, with a circular cross-section and a diameter of 2 mm. Of course, in other embodiments, the diameter is 1 mm, 1.5 mm, etc. can be used.

Embodiment 2

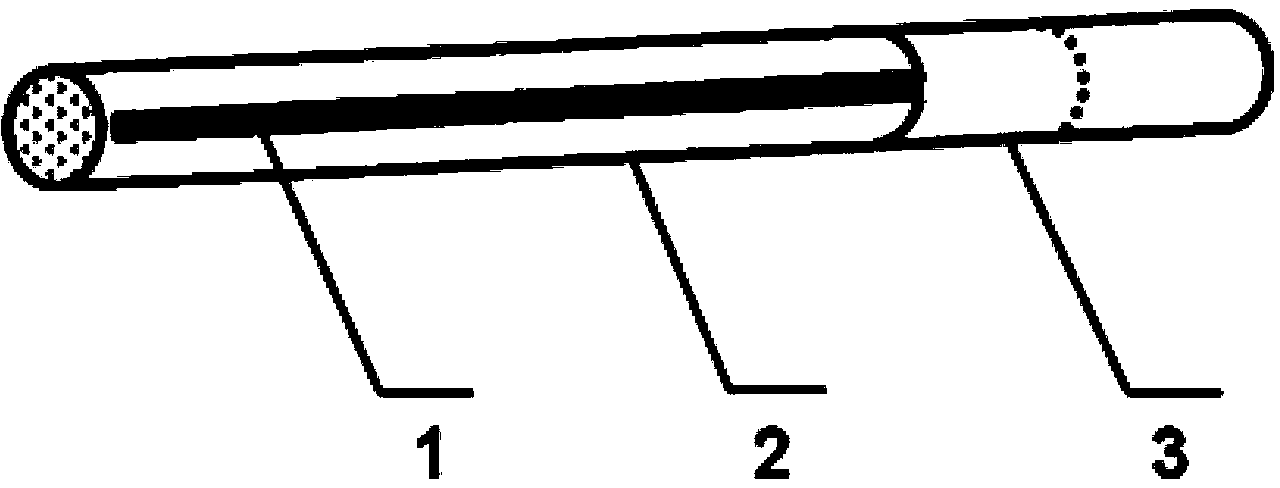

[0026] see figure 2 , the cigarette with temperature regulating function in this embodiment includes a filter rod 3, a shredded tobacco rod 2 and a thermal conductor 1 arranged in the shredded tobacco rod 2, along the longitudinal direction of the shredded tobacco rod, the thermal conductor 1 is loaded at the center of the shredded tobacco rod , its end (the end in contact with the filter rod) extends into the junction of the tobacco rod and the filter rod, and the head end (ignition end) is 3mm away from the end face of the tobacco rod. The heat conductor in this embodiment is in the shape of a quadrangular prism with a square cross section and a side length of 2 mm.

Embodiment 3

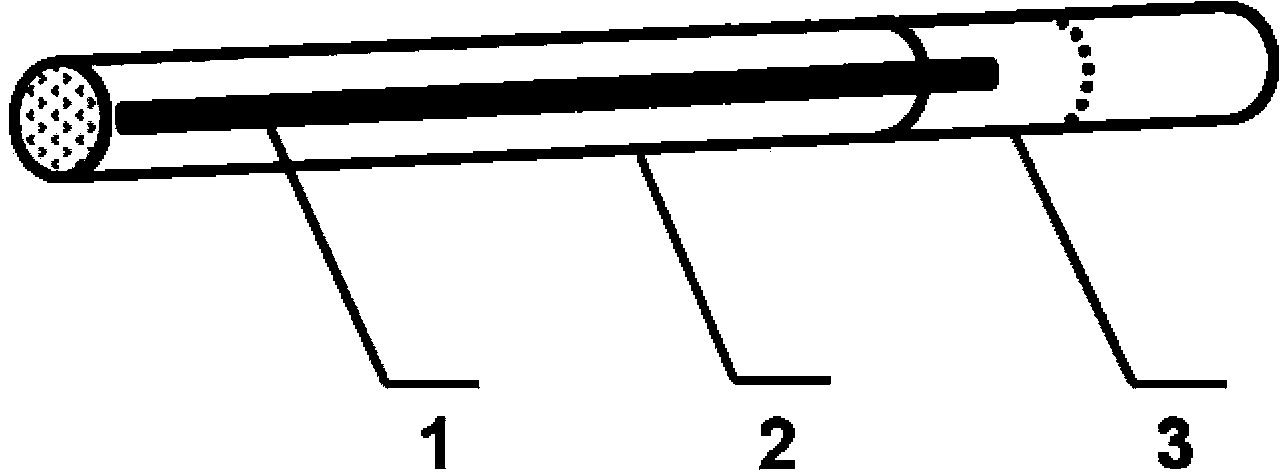

[0028] see image 3 , the cigarette with temperature regulating function in this embodiment includes a filter rod 3, a shredded tobacco rod 2 and a thermal conductor 1 arranged in the shredded tobacco rod 2, along the longitudinal direction of the shredded tobacco rod, the thermal conductor 1 is loaded at the center of the shredded tobacco rod , the end (the end in contact with the filter rod) is inserted into the filter rod 5mm, and the head end (ignition end) is 2mm away from the end face of the tobacco rod. The good thermal conductor in this embodiment is in the shape of a cylinder with a circular cross section and a diameter of 2 mm.

[0029] Compared with Embodiment 1 and Embodiment 2, in this embodiment, since the heat conductor extends into the filter rod, the heat of the combustion cone can be directly transferred to the microcapsules, Porous adsorption materials, dripping pills, etc., so that the essence can be released at a higher temperature, and the utilization ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com